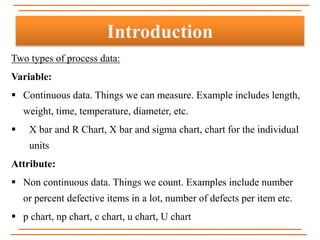

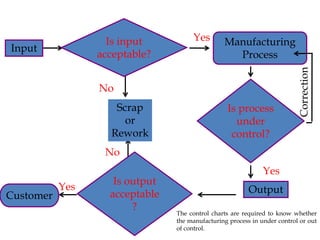

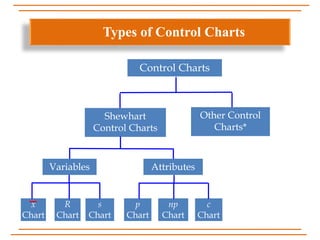

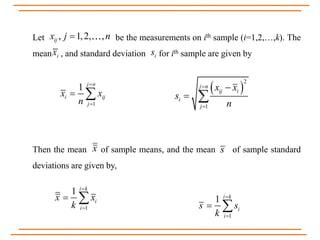

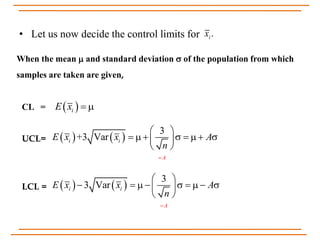

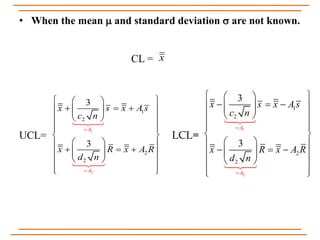

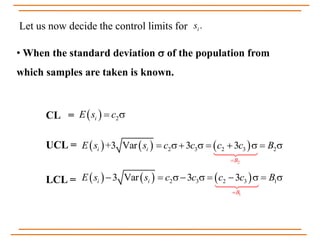

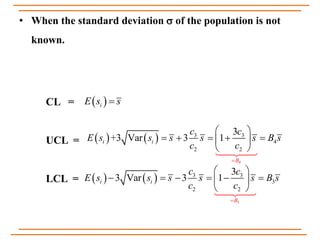

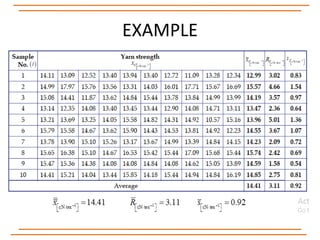

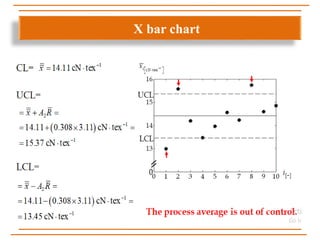

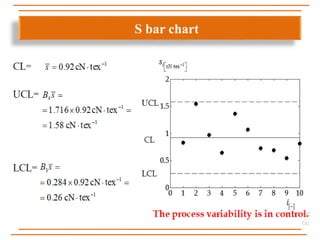

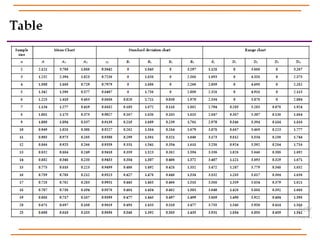

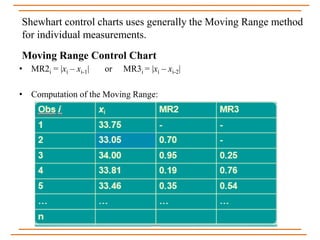

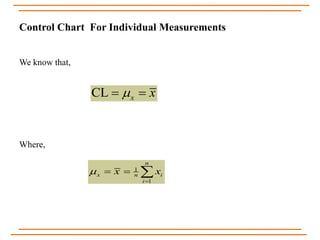

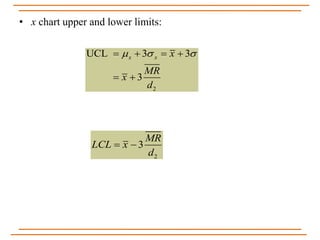

The document discusses statistical process control, specifically x, s, and Shewhart control charts for individual measurements. It highlights the importance of control charts in determining if a manufacturing process is in control or out of control, detailing types of data and various control chart methods. Additionally, it provides formulas for calculating control limits using known and unknown population parameters.