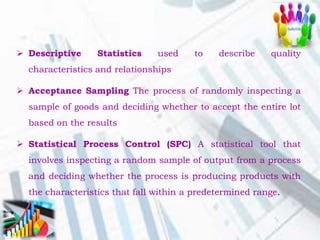

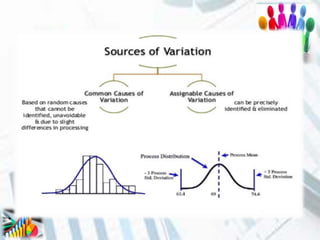

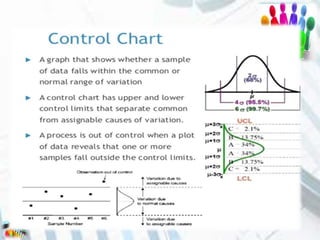

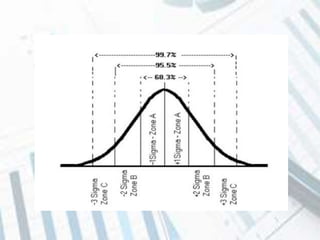

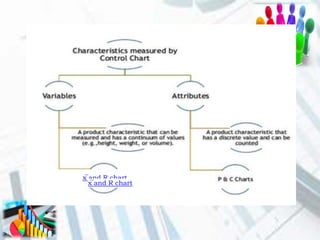

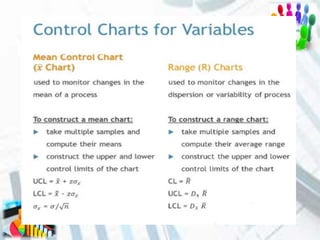

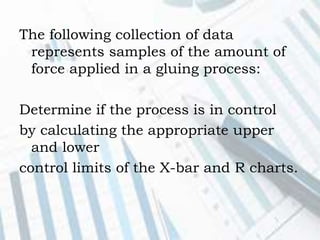

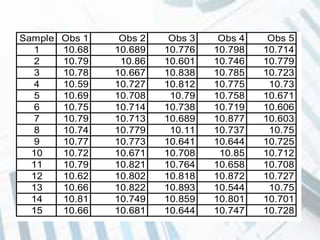

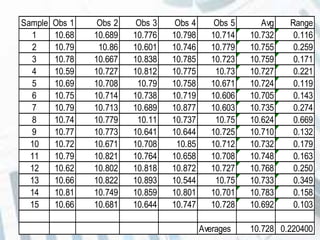

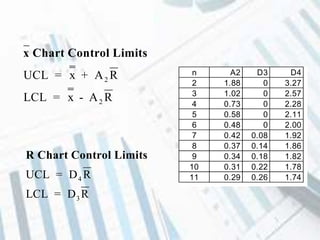

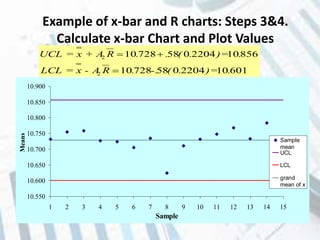

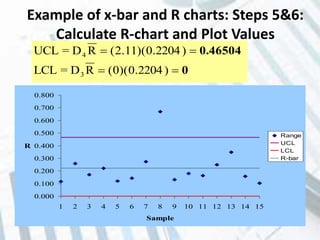

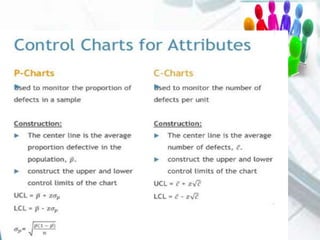

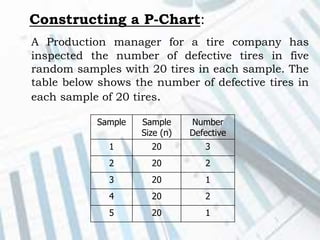

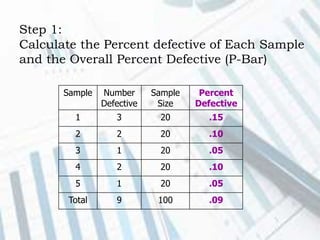

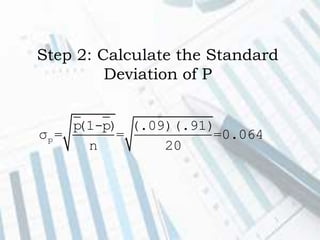

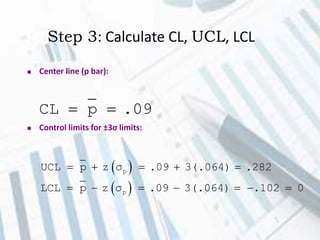

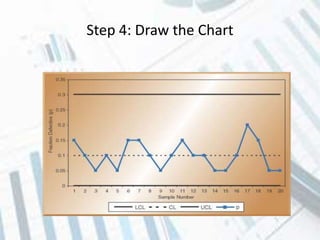

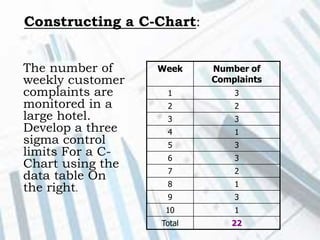

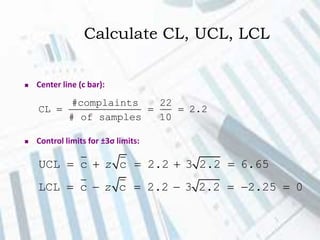

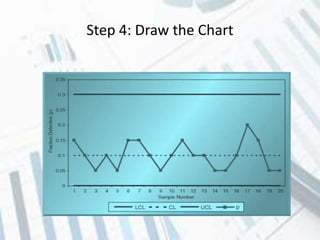

The document discusses quality control and statistical quality control. It defines quality as properties valued by consumers and quality control as maintaining standards through testing samples. The goal of quality control is to eliminate nonconformities and wasted resources at lowest cost. Statistical quality control uses statistical tools like descriptive statistics, acceptance sampling, and statistical process control to measure and control variation in processes. Examples are provided of x-bar and R charts to determine if a gluing process is in control, as well as P and C charts to monitor defects and complaints.