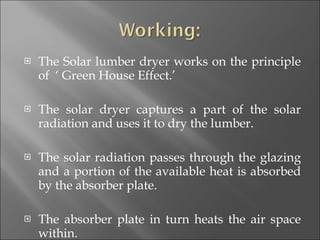

- The document discusses the design, construction, and working of a solar lumber dryer. It aims to provide a controlled drying method for lumber using solar energy as an alternative to open-air drying or expensive high-temperature dryers.

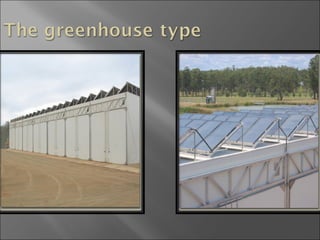

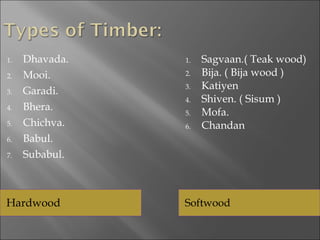

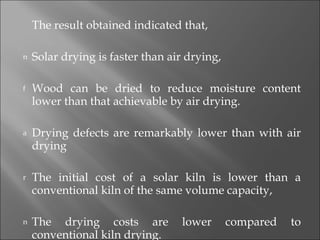

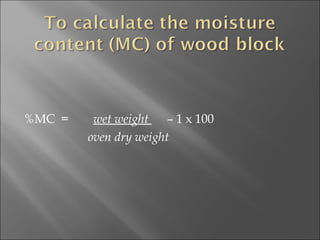

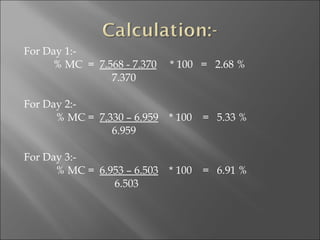

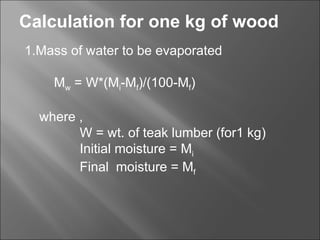

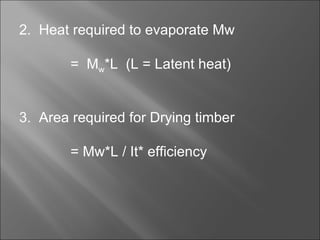

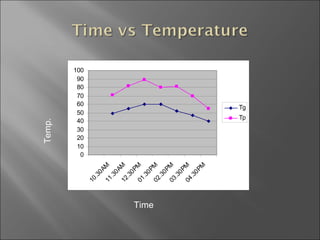

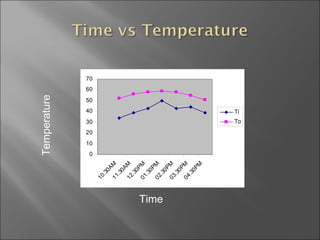

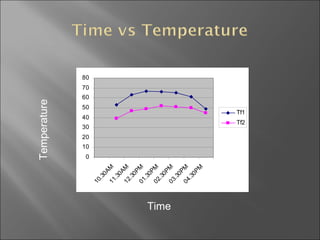

- Key aspects covered include classifications of solar dryers, materials commonly dried, advantages over traditional drying methods like reduced costs, defects, and drying times. Calculations are presented on moisture content reduction during drying and heat requirements.

- Applications mentioned include drying wood, agricultural crops, herbs, spices and more wherever hot air is needed for controlled drying. In conclusion, solar drying is found to be effective and cheaper than normal sun drying for tropical regions.