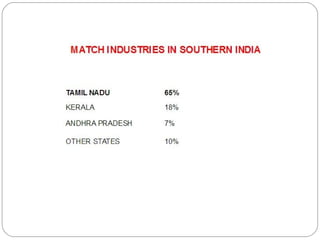

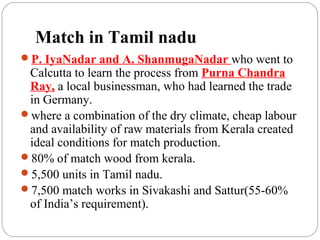

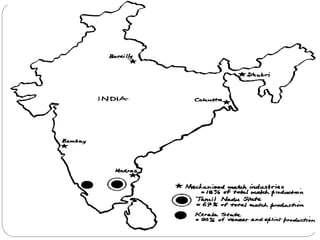

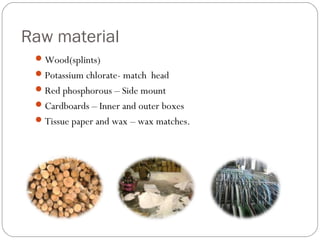

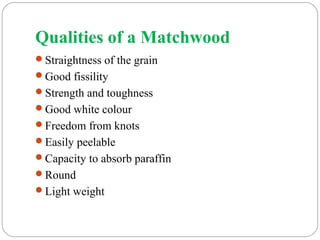

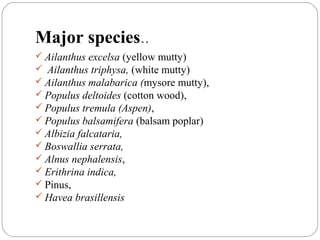

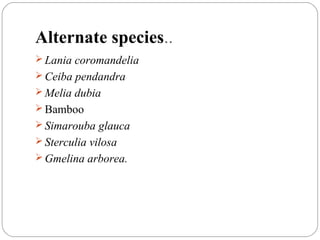

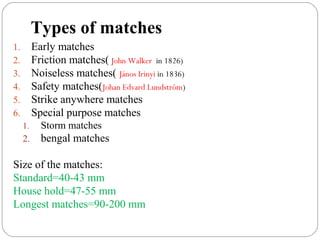

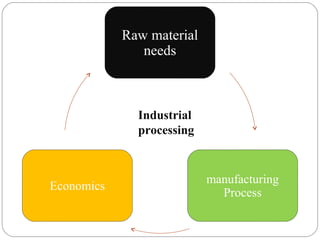

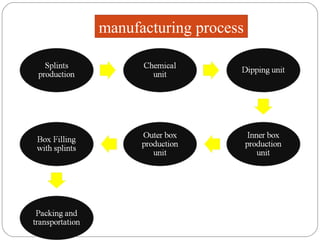

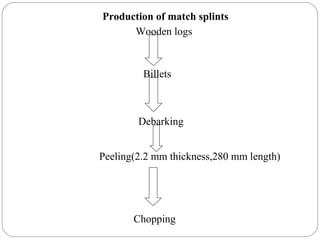

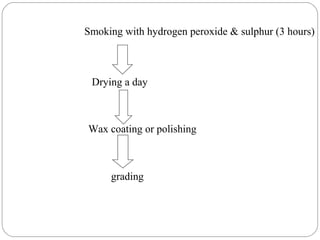

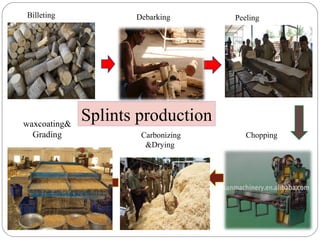

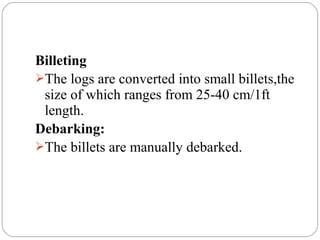

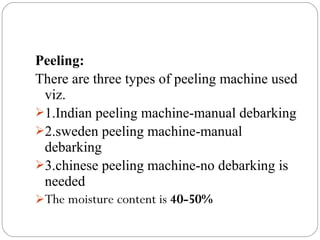

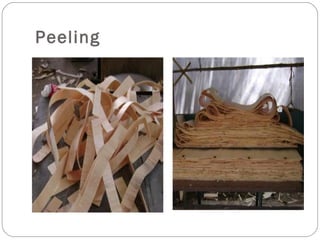

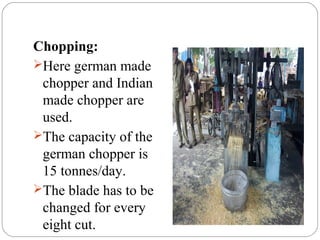

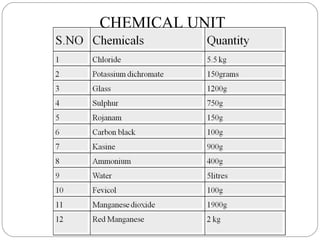

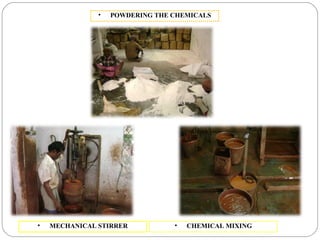

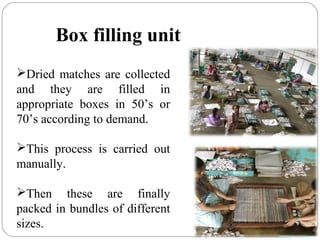

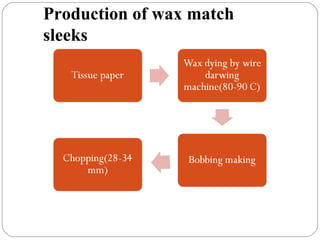

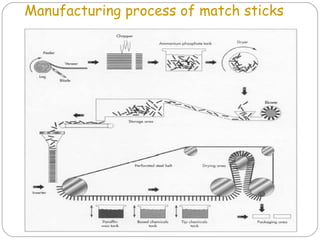

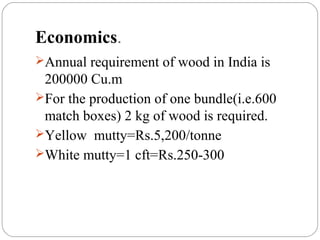

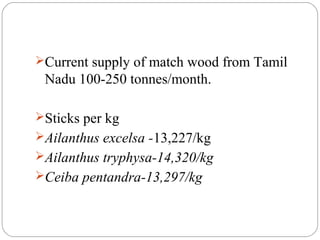

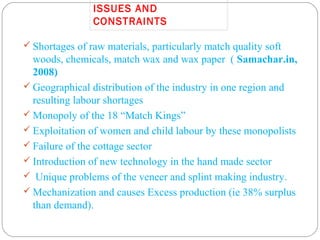

The document discusses the match manufacturing process in India. It begins with the history of matches and their invention in China and Europe. It then discusses how the match industry developed in India, primarily in Southern India, using local wood species. The key steps of the manufacturing process are described, including wood collection and processing, chemical mixing, dipping sticks in the chemicals, drying, boxing, and packing. The major wood species used are yellow mutty, white mutty, and cottonwood. The document also provides statistics on the scale and economics of the match industry in India.