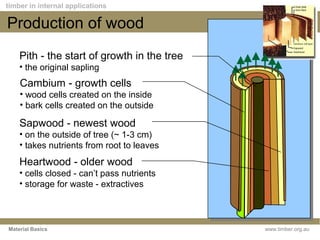

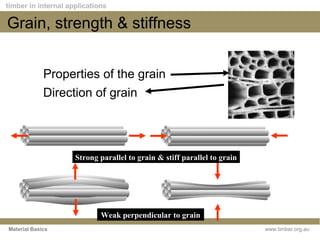

This document provides information on the material properties and characteristics of timber. It discusses that timber is a natural product made of wood from trees. It grows in rings and its properties vary based on species and growth conditions. The document outlines the production of wood within trees and describes key characteristics like grain, moisture content, drying, and shrinkage. It also discusses grading standards and jointing methods for timber.