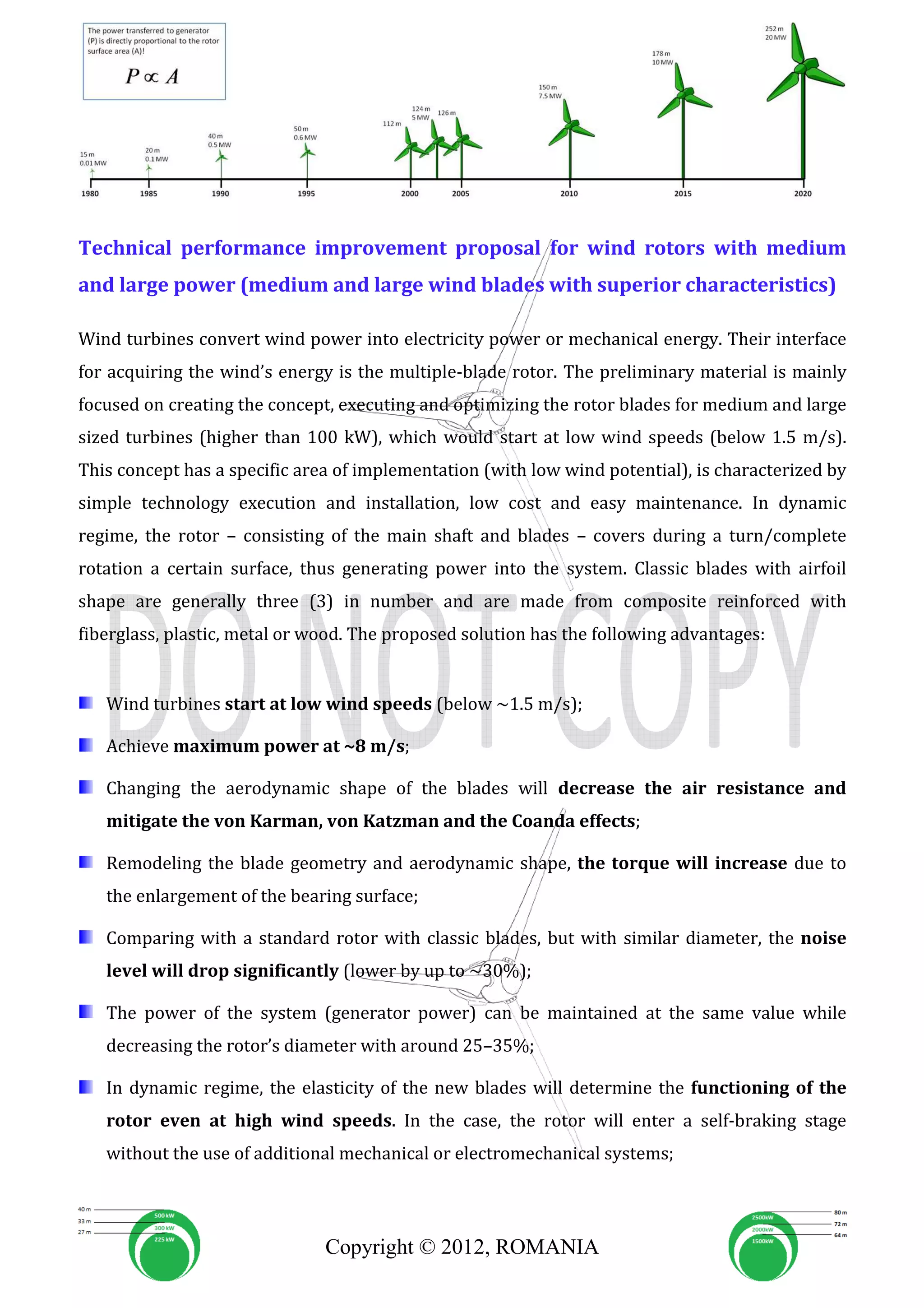

The document proposes technical improvements to wind rotors for medium and large turbines over 100 kW. The improvements include starting at lower wind speeds below 1.5 m/s, achieving maximum power at 8 m/s, reducing air resistance, and decreasing noise levels by up to 30%. Redesigning the blade geometry could increase torque and maintain the same power output while decreasing rotor diameter by 25-35%. Collaboration is sought to develop experimental prototypes using at least two medium power turbines to test and optimize the design for large turbines.