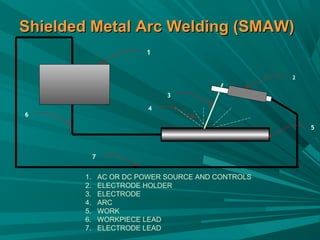

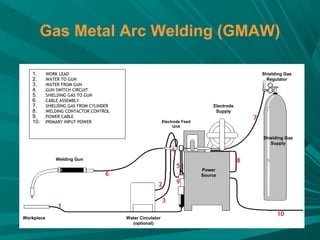

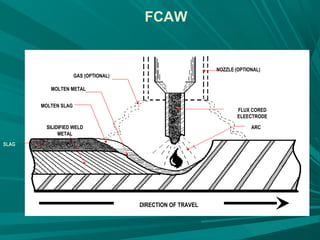

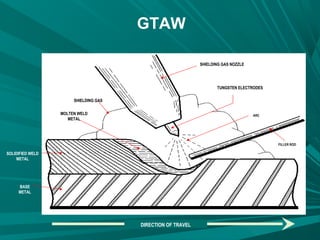

Welding is a process where two metal pieces are joined by heating them with an electric arc or gas flame with an electrode or gas torch, with or without the application of pressure. There are several common welding processes including shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux cored arc welding (FCAW), gas tungsten arc welding (GTAW), and submerged arc welding (SAW). Each process has advantages for different applications but also limitations.