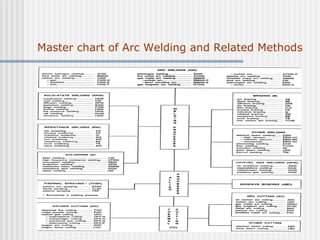

The document summarizes various welding techniques. It describes the key types of welding including arc welding processes like shielded metal arc welding, gas tungsten arc welding, flux cored arc welding and gas metal arc welding. It also discusses oxy-fuel welding and resistance welding. For each technique, it provides details on the equipment, process and applications as well as advantages and limitations.