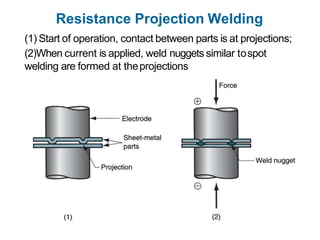

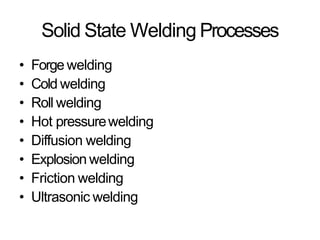

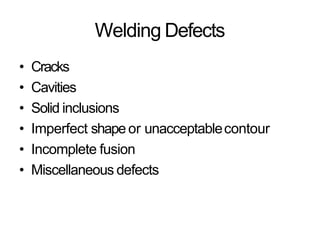

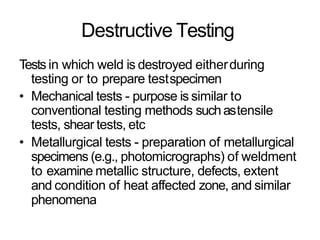

The document discusses advanced welding technologies, including various welding processes such as arc welding, resistance welding, oxyfuel gas welding, and solid state welding. It provides details on common arc welding processes like shielded metal arc welding, gas metal arc welding, flux-cored arc welding, submerged arc welding, and gas tungsten arc welding. The summary discusses the key welding processes, their characteristics, and applications.