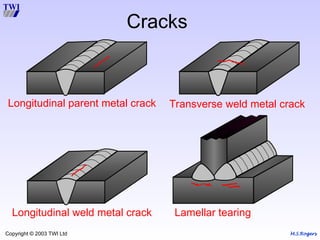

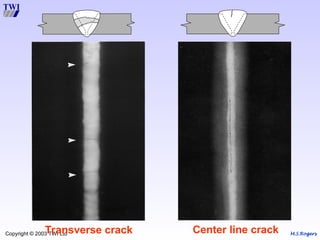

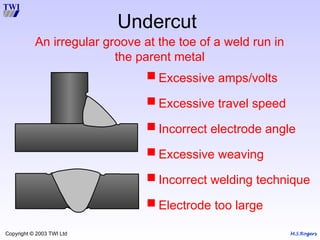

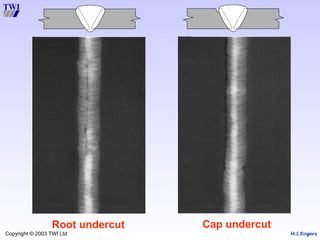

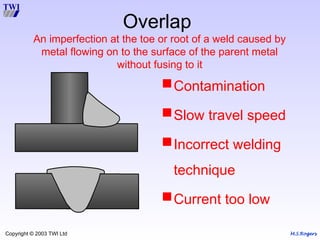

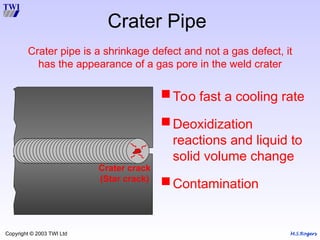

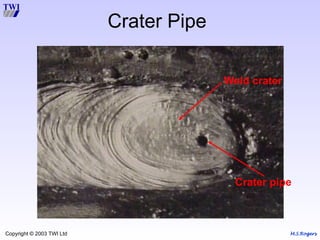

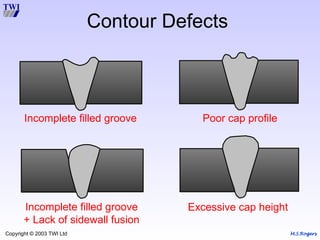

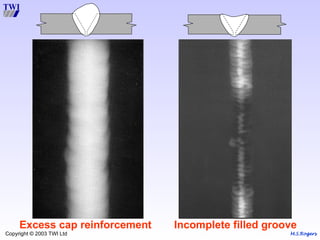

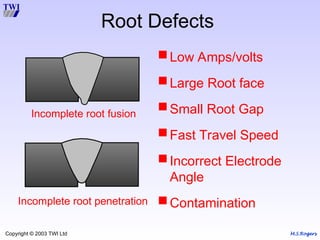

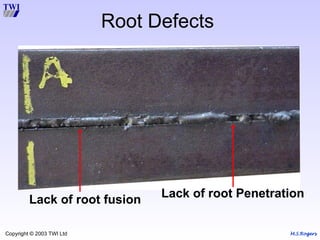

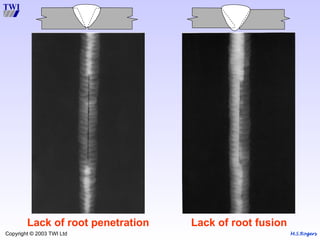

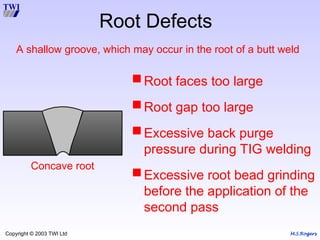

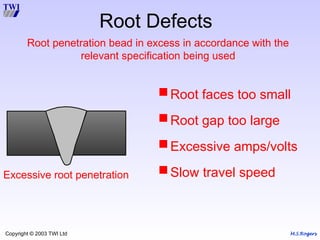

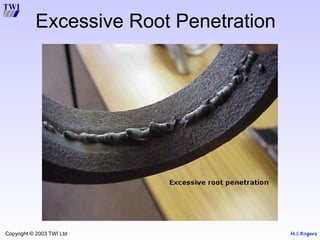

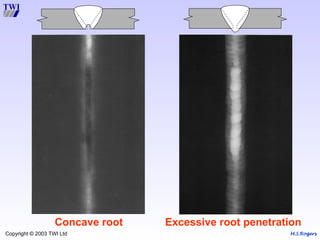

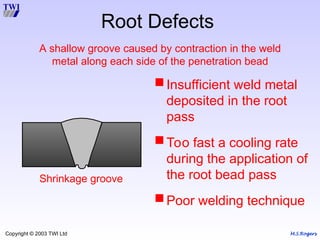

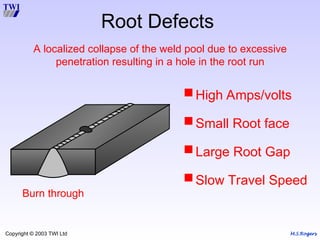

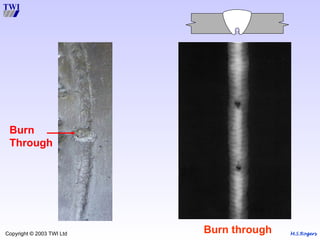

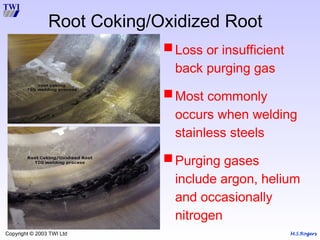

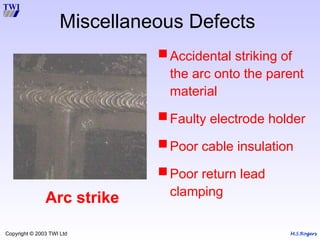

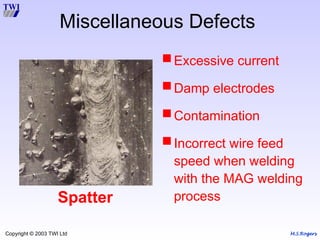

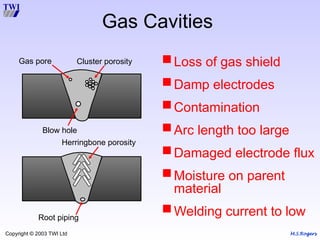

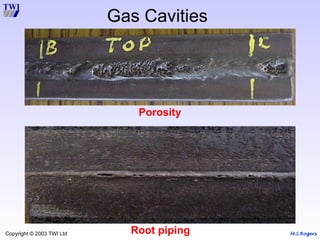

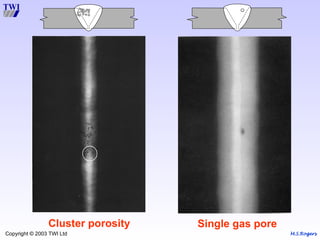

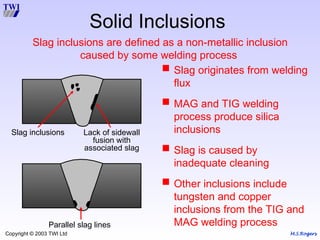

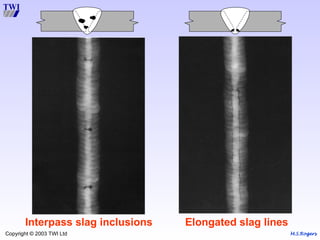

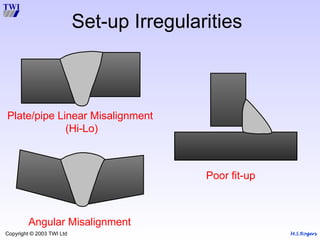

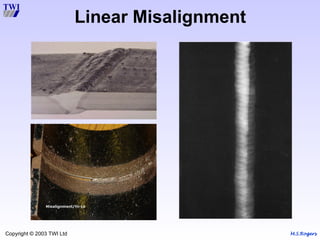

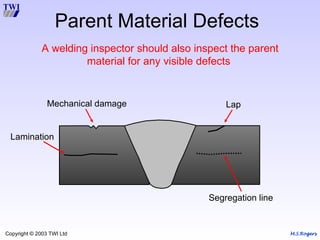

The document outlines various types of weld defects categorized into five main groups: cracks, surface irregularities, contour defects, root defects, and miscellaneous defects. It also discusses the causes of these defects, such as incorrect welding techniques and material conditions, and emphasizes the importance of inspection and weld repair methods to maintain structural integrity. Furthermore, it poses questions regarding defect identification and repair processes in welding inspection.