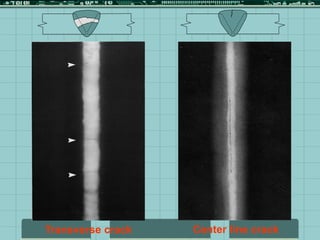

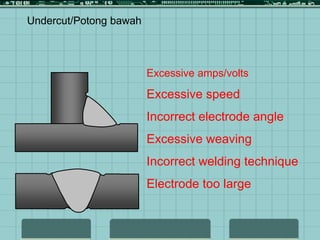

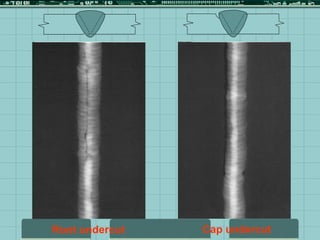

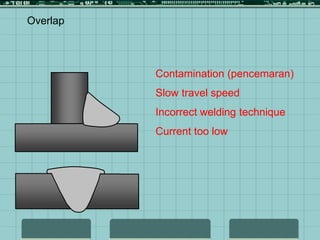

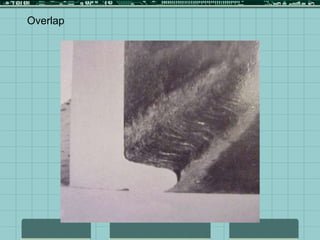

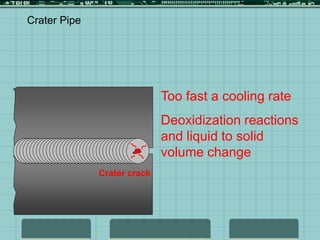

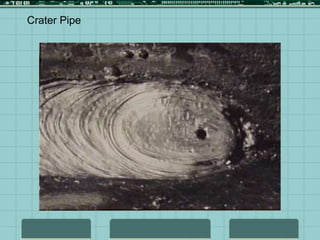

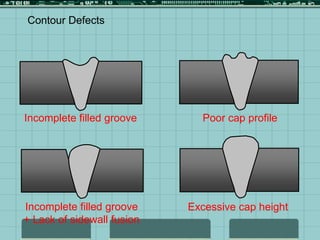

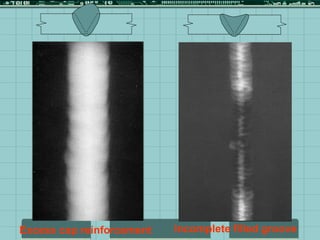

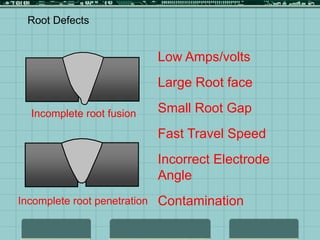

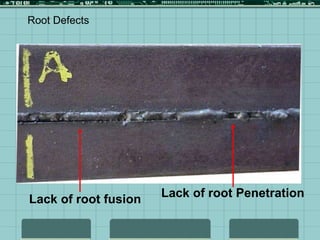

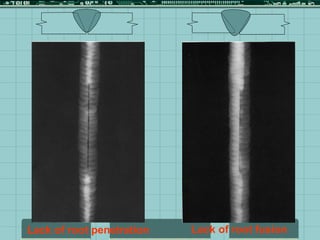

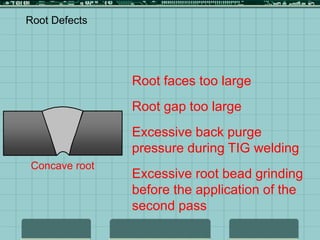

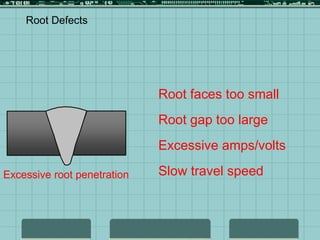

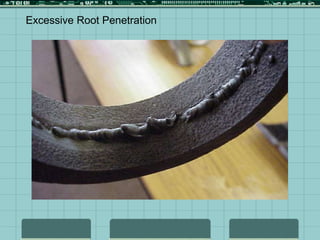

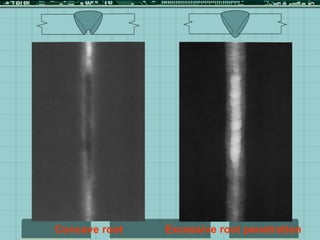

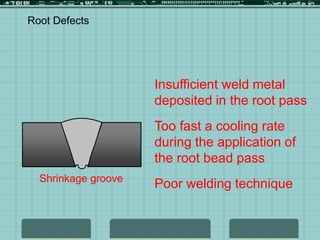

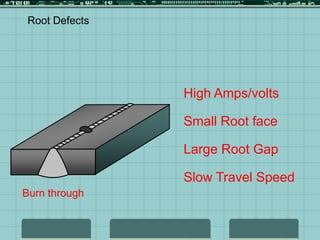

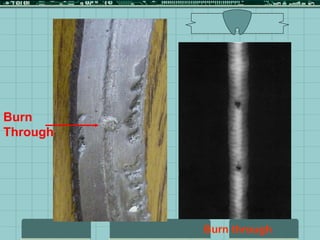

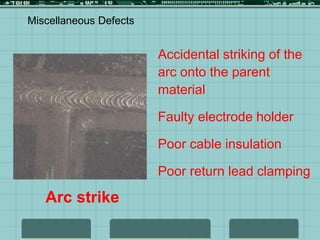

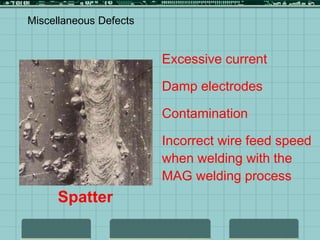

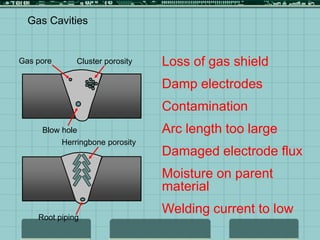

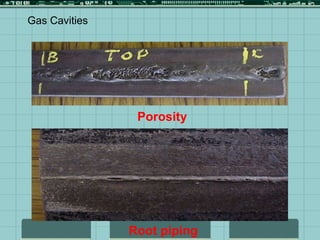

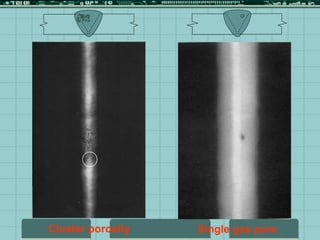

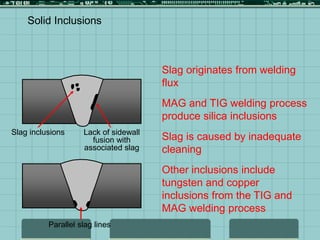

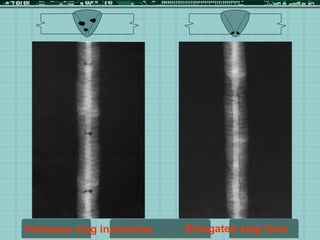

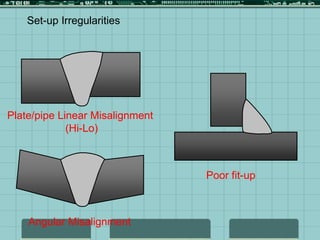

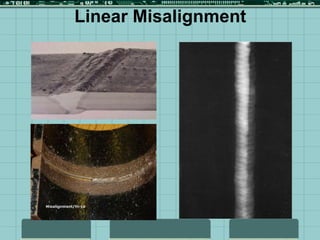

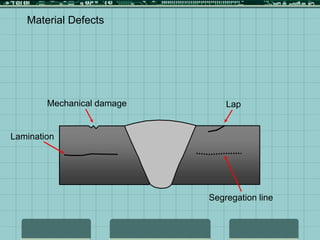

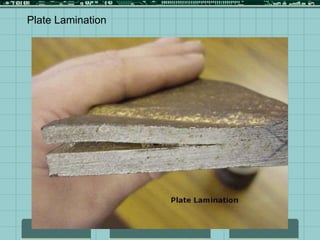

The document discusses various welding defects including cracks, surface defects, contour defects, root defects, and miscellaneous defects. It provides details on specific types of each defect such as undercut, overlap, incomplete root fusion, gas porosity, slag inclusions, and their potential causes like incorrect welding technique, contamination, or material defects. Various repair methods are also mentioned such as grinding, chipping, and arc air gouging.