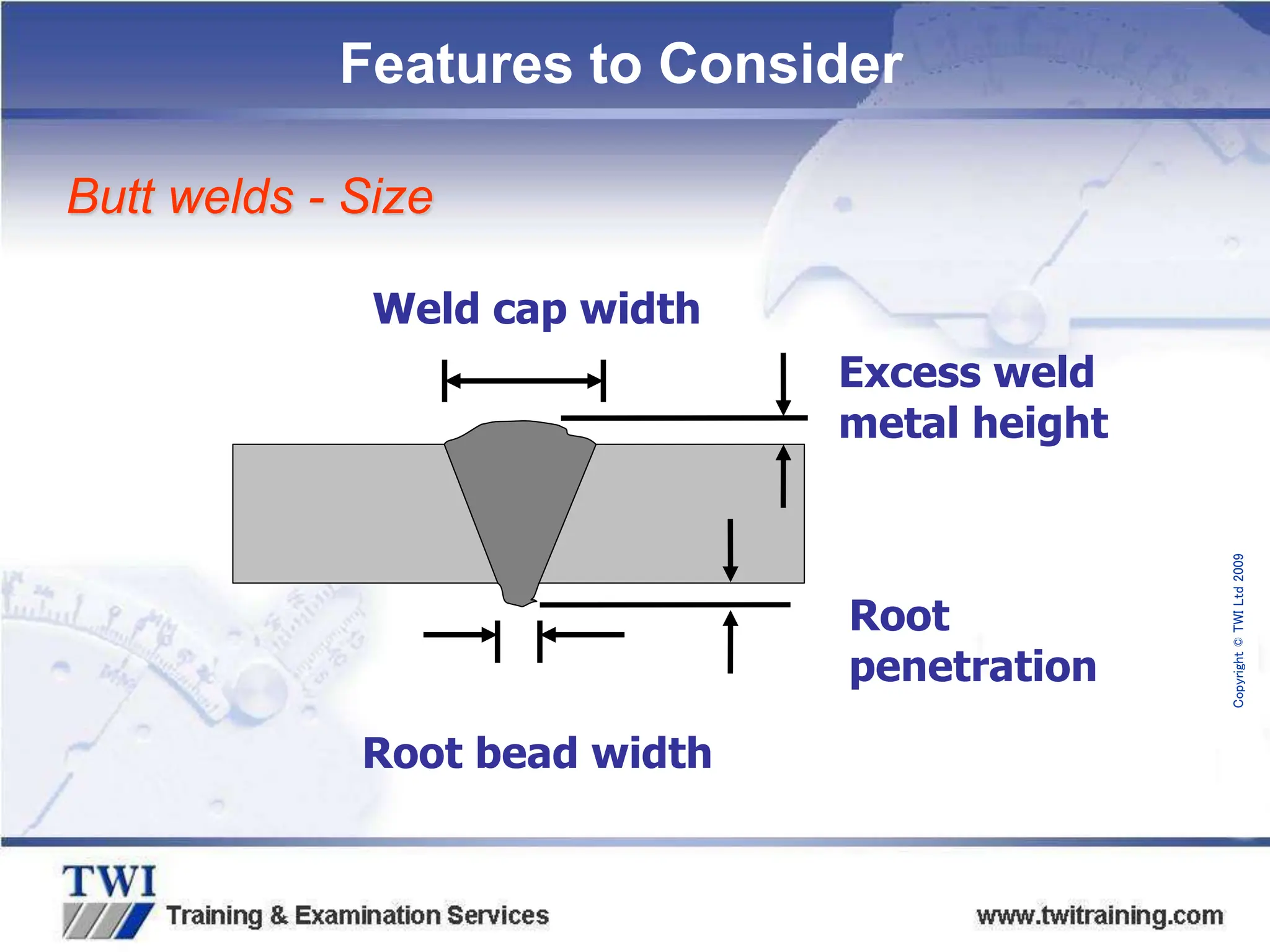

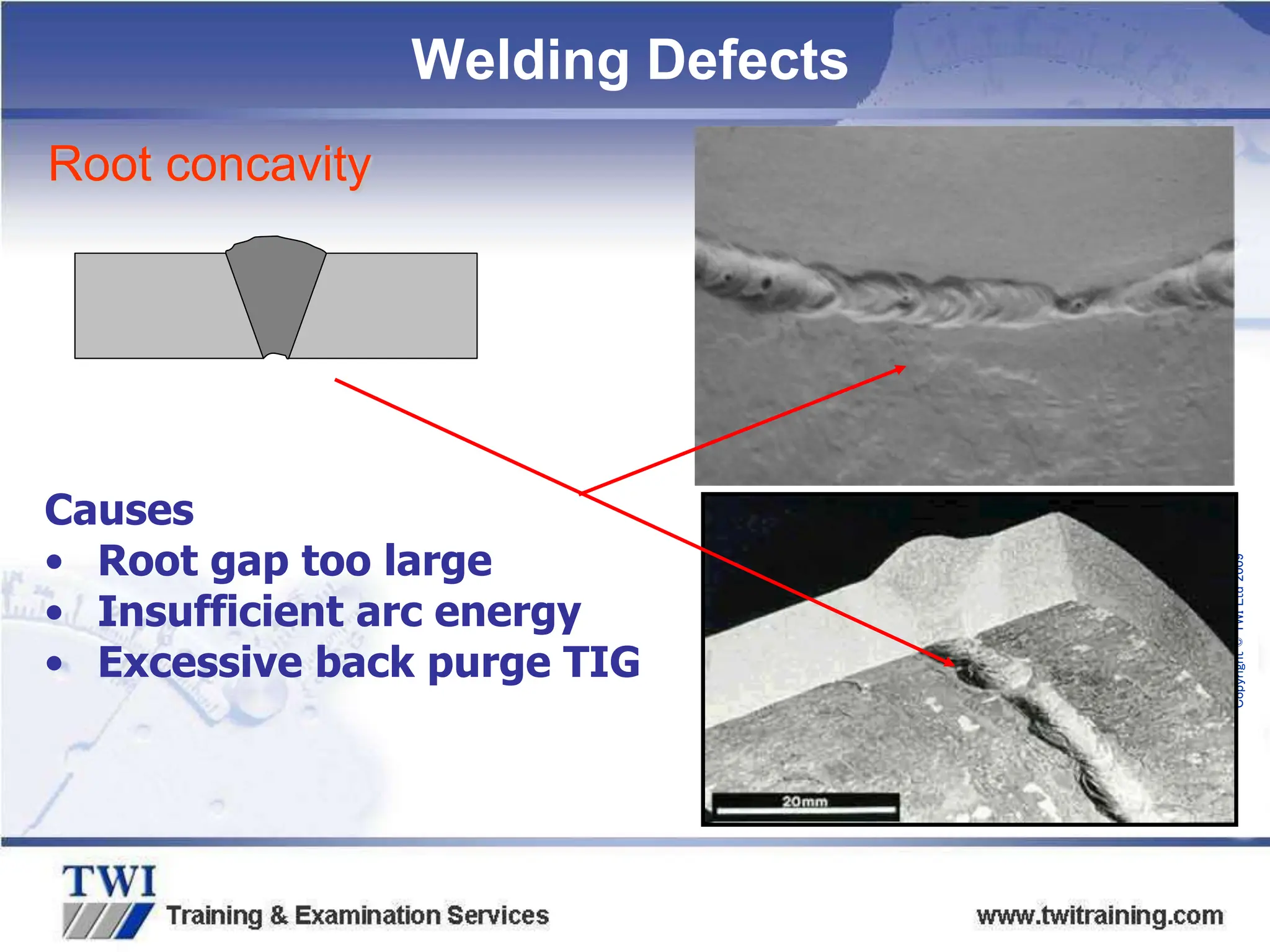

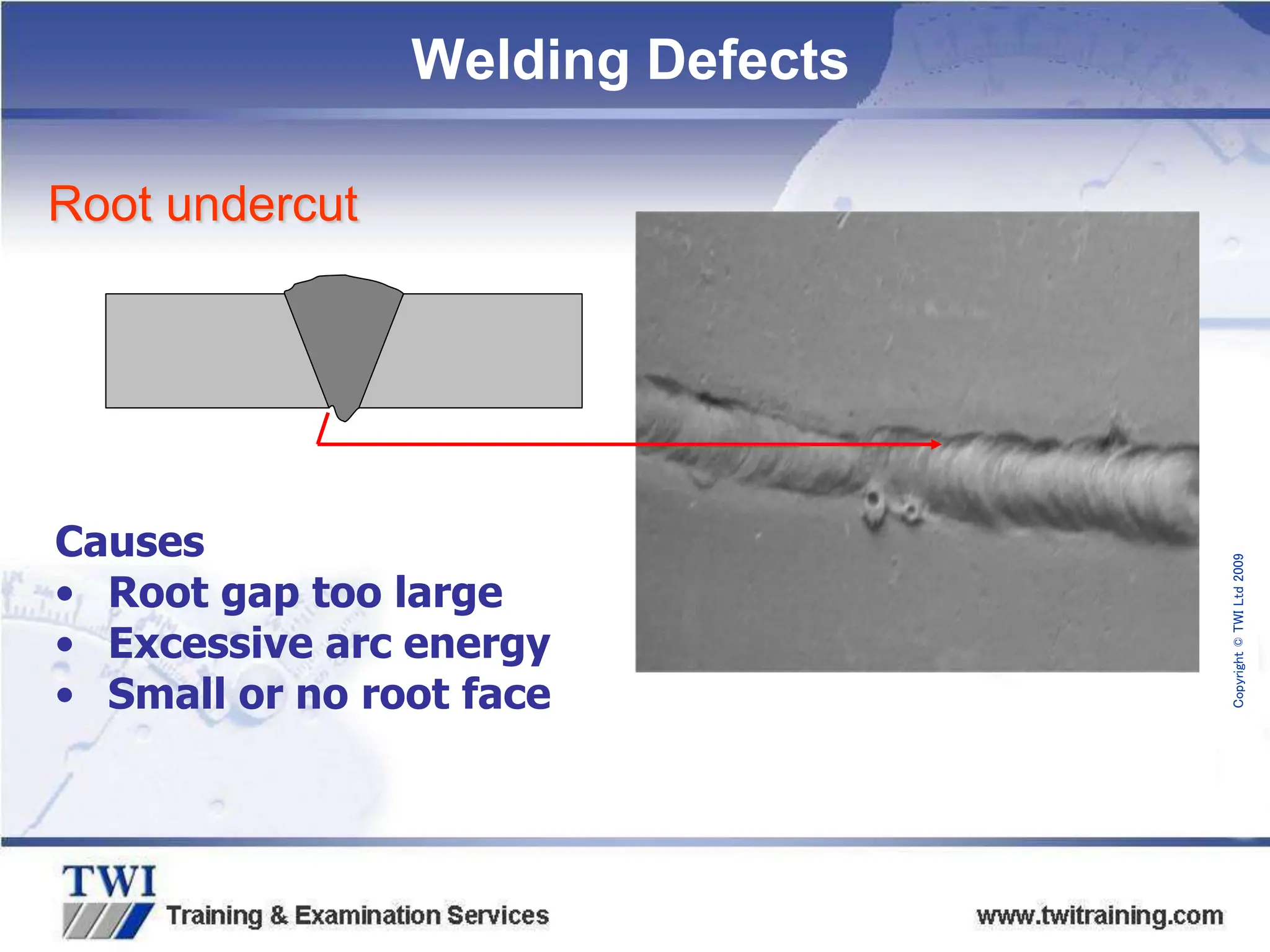

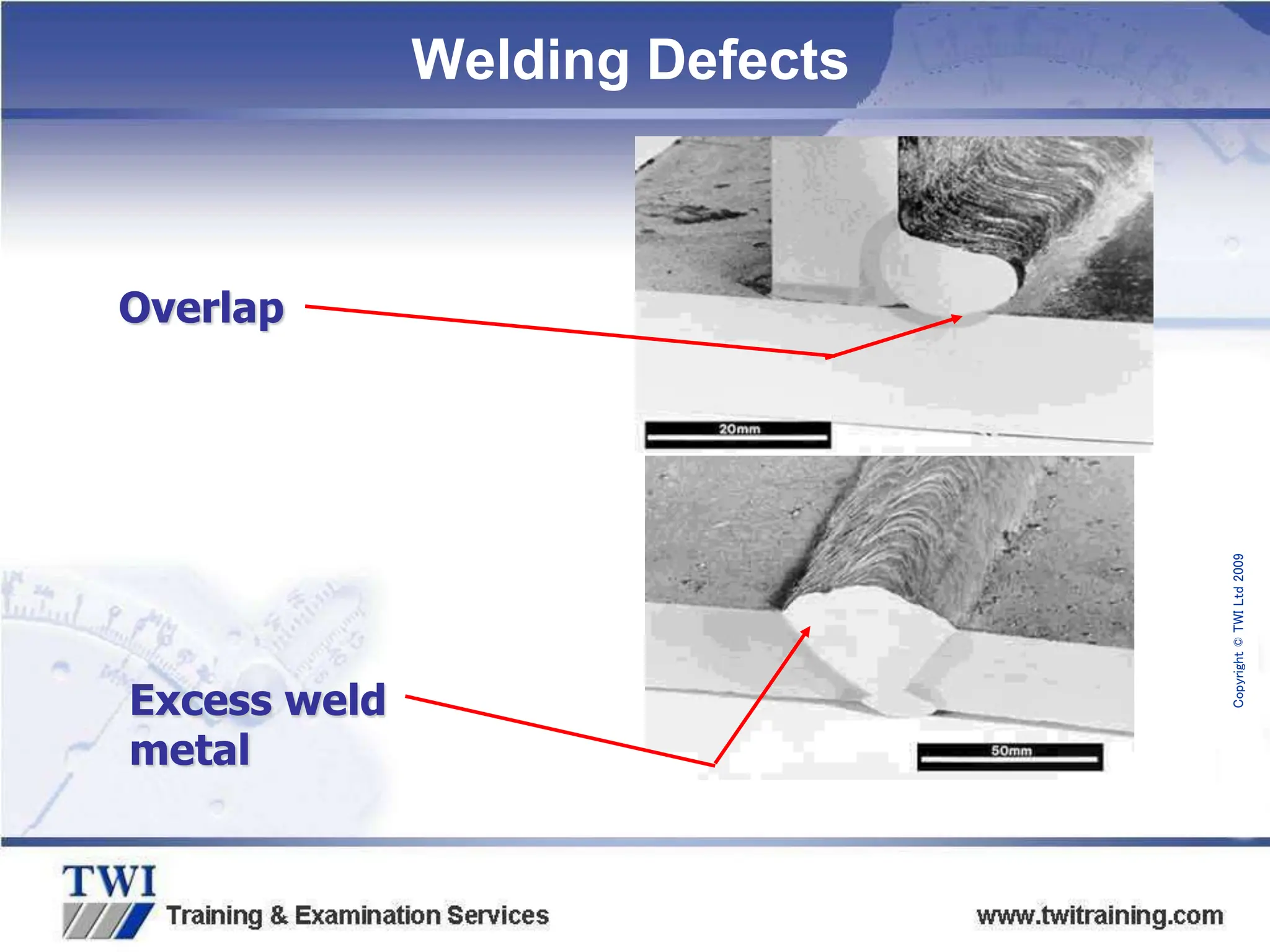

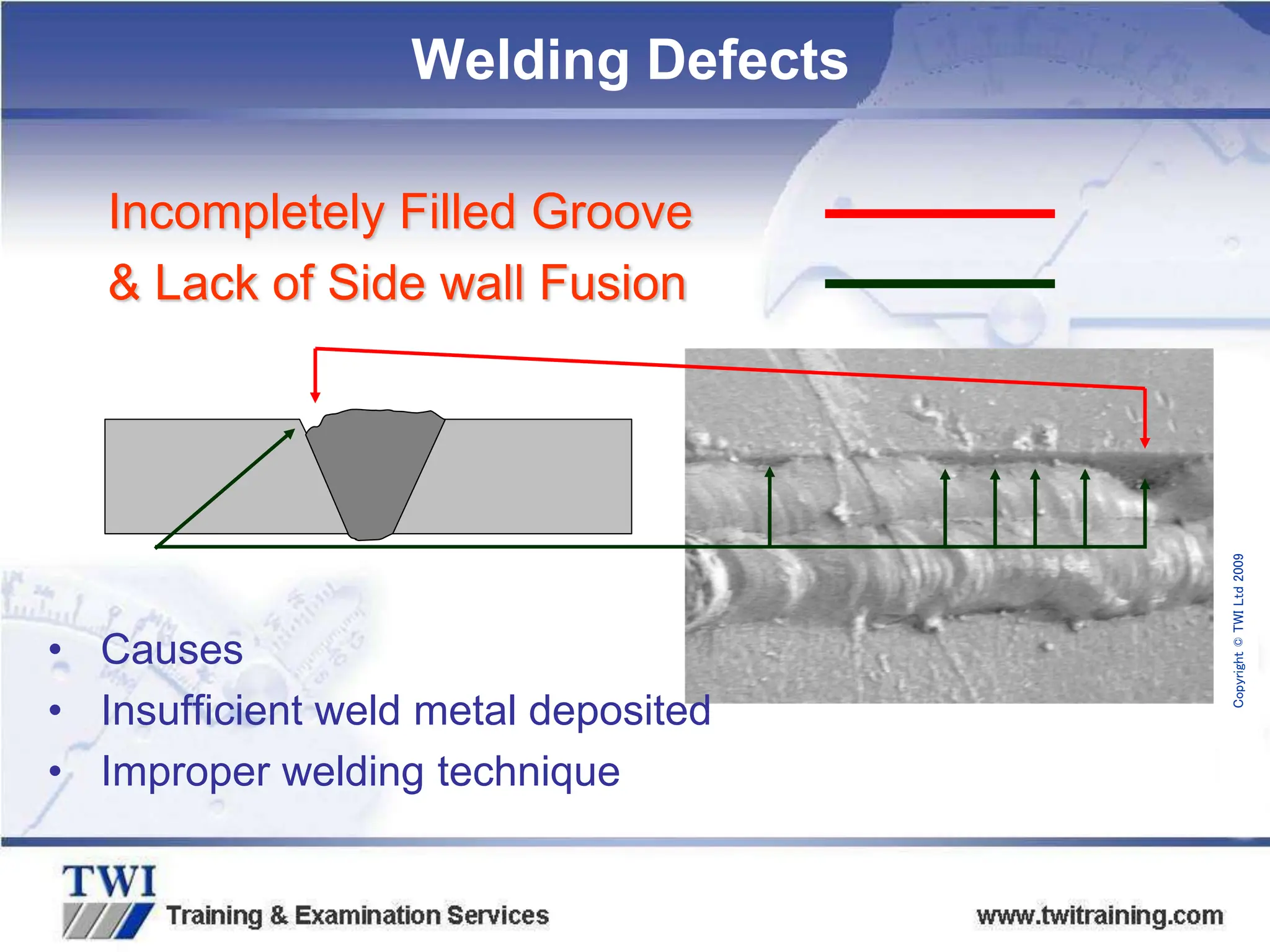

The document discusses various welding defects such as incomplete root penetration, root concavity, excess root penetration, root undercut, cap undercut, overlap, lack of fusion, incompletely filled groove, porosity, slag inclusions, tungsten inclusions, burn through, spatter, arc strikes, mechanical damage, non-alignment, angular distortion, linear misalignment, excess weld metal height, and excess penetration. It provides the causes and examples of each defect.