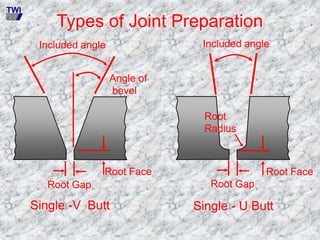

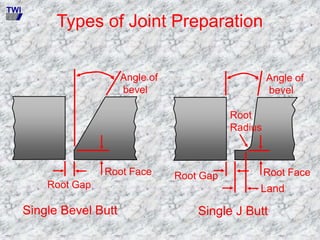

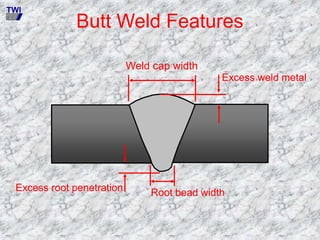

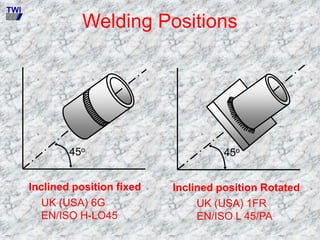

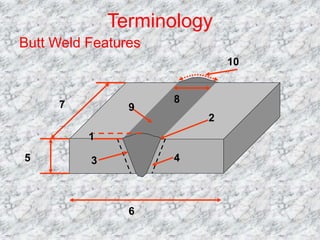

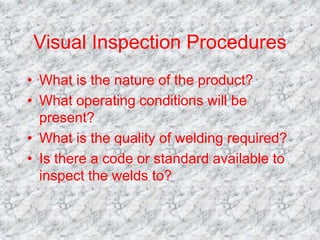

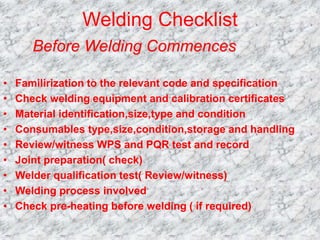

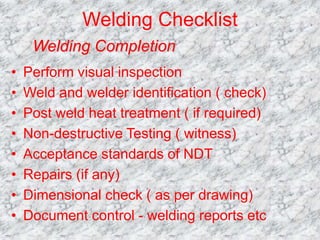

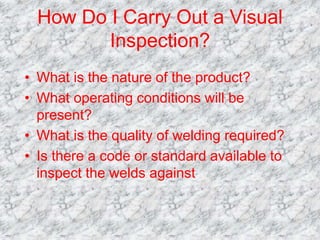

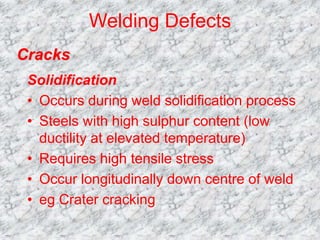

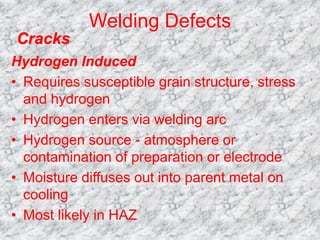

This document provides information on visual welding inspection for butt and fillet welds. It covers terminology used in welding inspection, types of joint preparation and welds, welding positions, weld features to examine, common weld defects to identify, and the responsibilities and procedures of a welding inspector. The duties of a welding inspector include checking welding procedures, materials, and equipment before welding; monitoring the welding process; and performing visual and non-destructive testing after welding is complete. Key steps in a visual welding inspection are identifying applicable codes and standards, and examining weld size, profile, contours, roots, and surfaces for any defects.