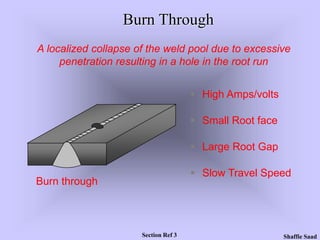

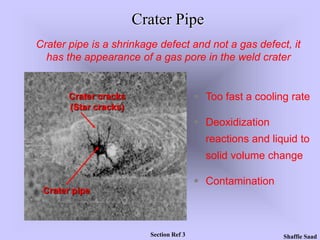

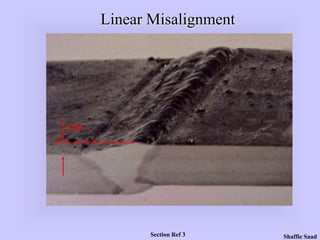

This document provides information on welding inspection and defects/repairs. It discusses various types of welding defects such as cracks, inclusions, lack of fusion, porosity and undercut. Specific defects like longitudinal cracks, slag inclusions, gas pores, overlap and lack of sidewall fusion are defined and illustrated. Potential causes of defects are provided. The document also covers inspection of parent materials, weld repairs and includes sample questions related to defects and repairs.