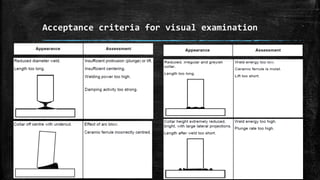

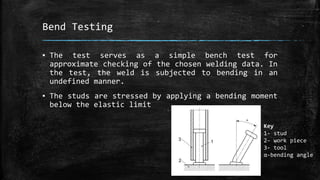

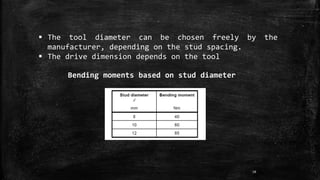

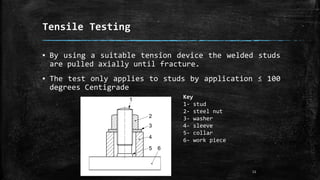

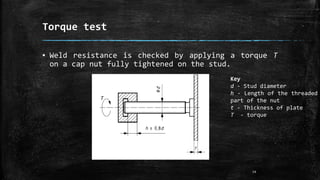

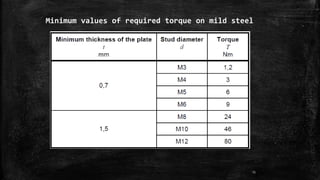

This document discusses quality inspection and testing procedures for arc stud welding of metallic materials. It outlines several acceptance criteria and testing methods, including visual examination of stud shape and size, bend testing to check for cracks below the elastic limit, tensile testing to ensure the stud's nominal strength is reached, torque testing of nuts on studs, and macro examinations and radiographic examinations to evaluate weld penetration depth and internal imperfections. Regular production tests are recommended to qualify welding procedures and ensure process control.