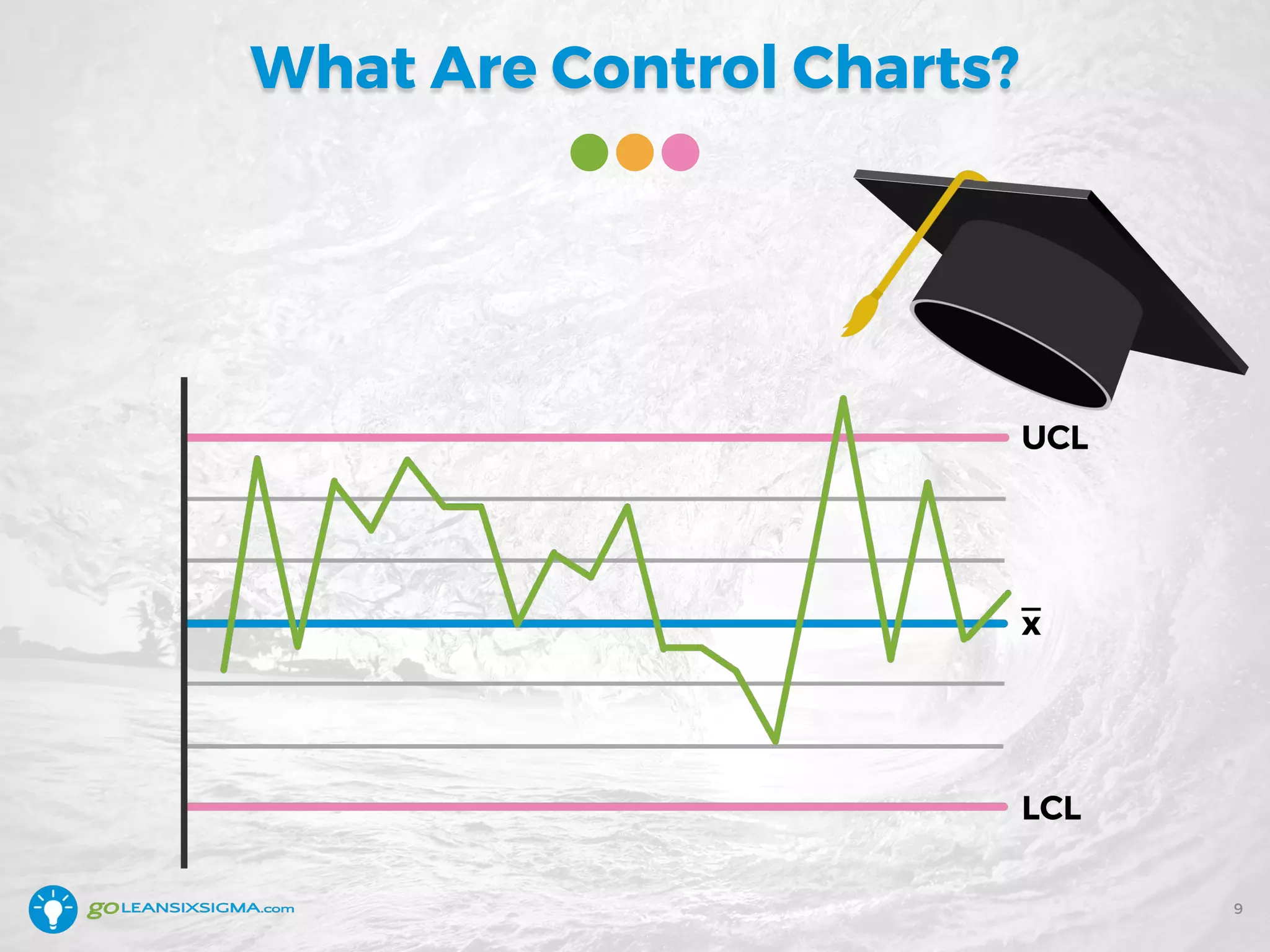

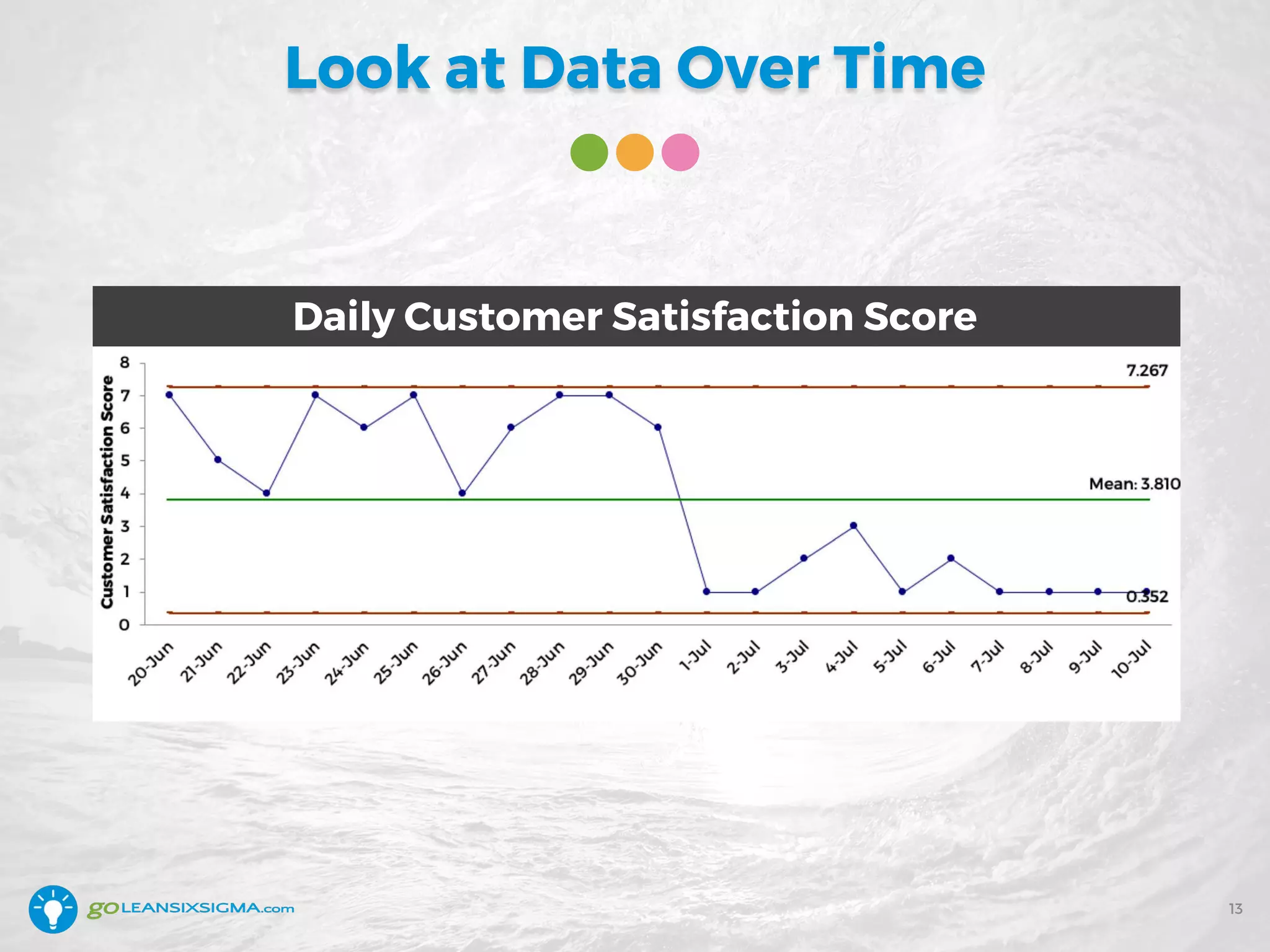

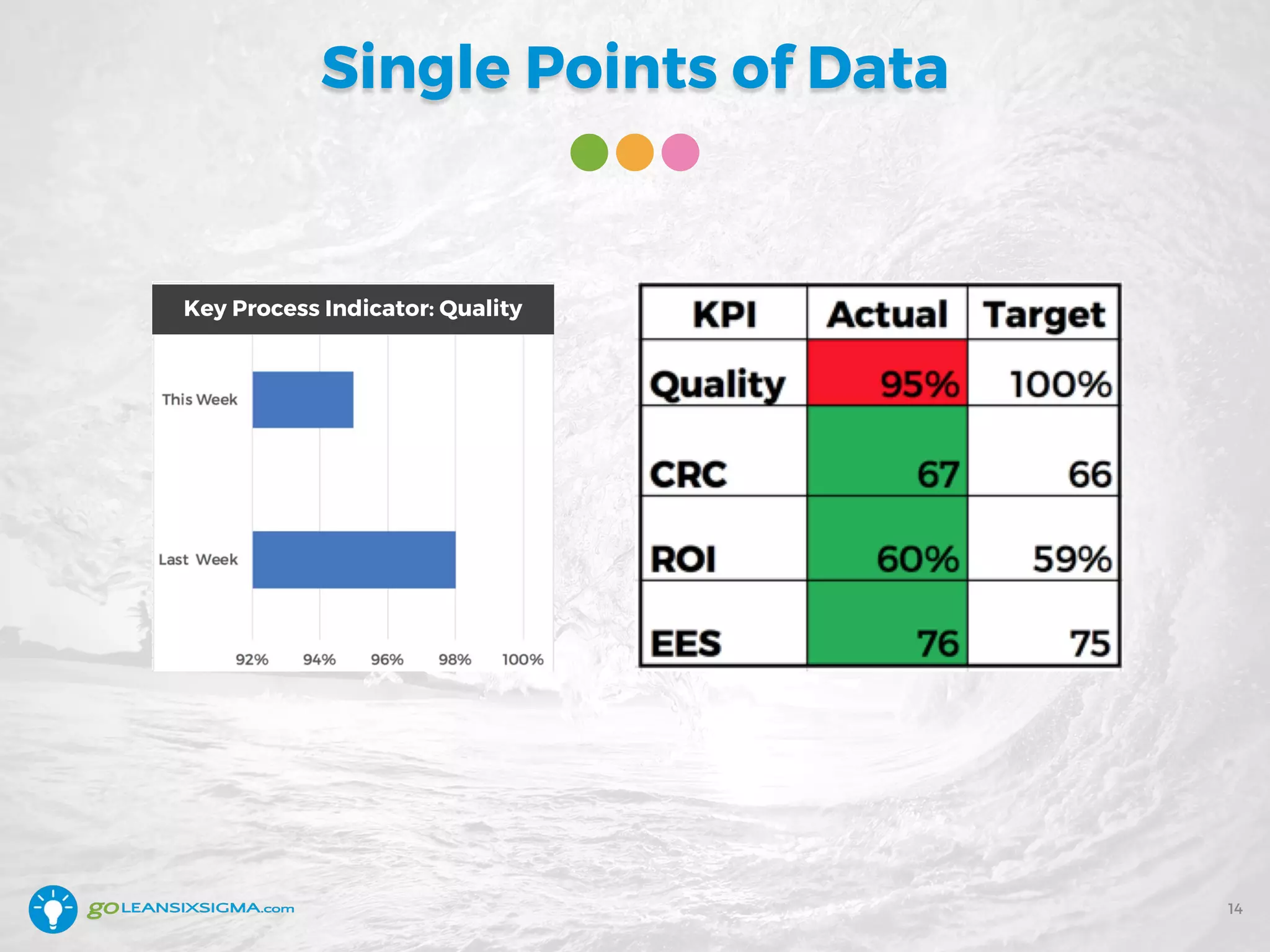

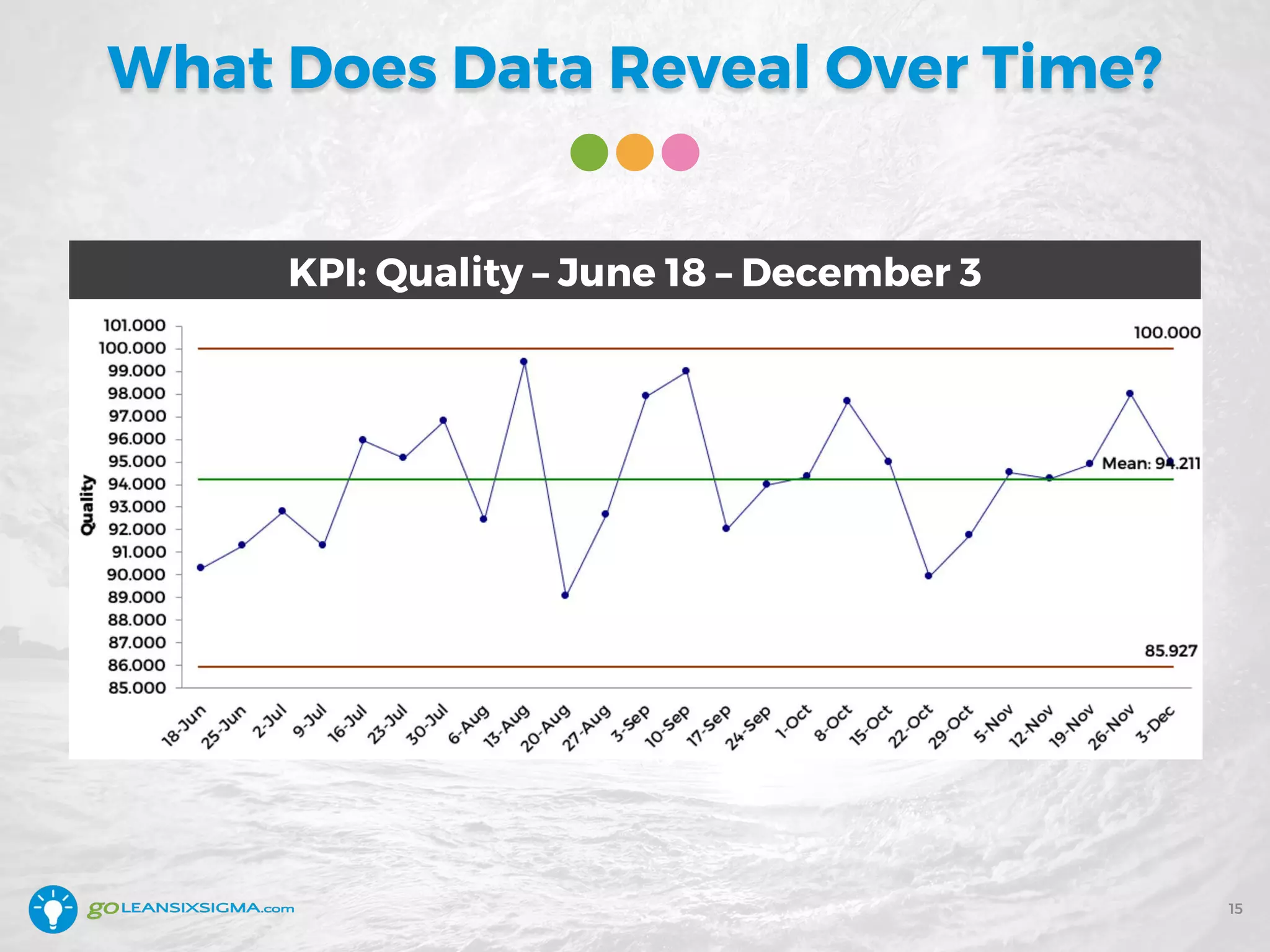

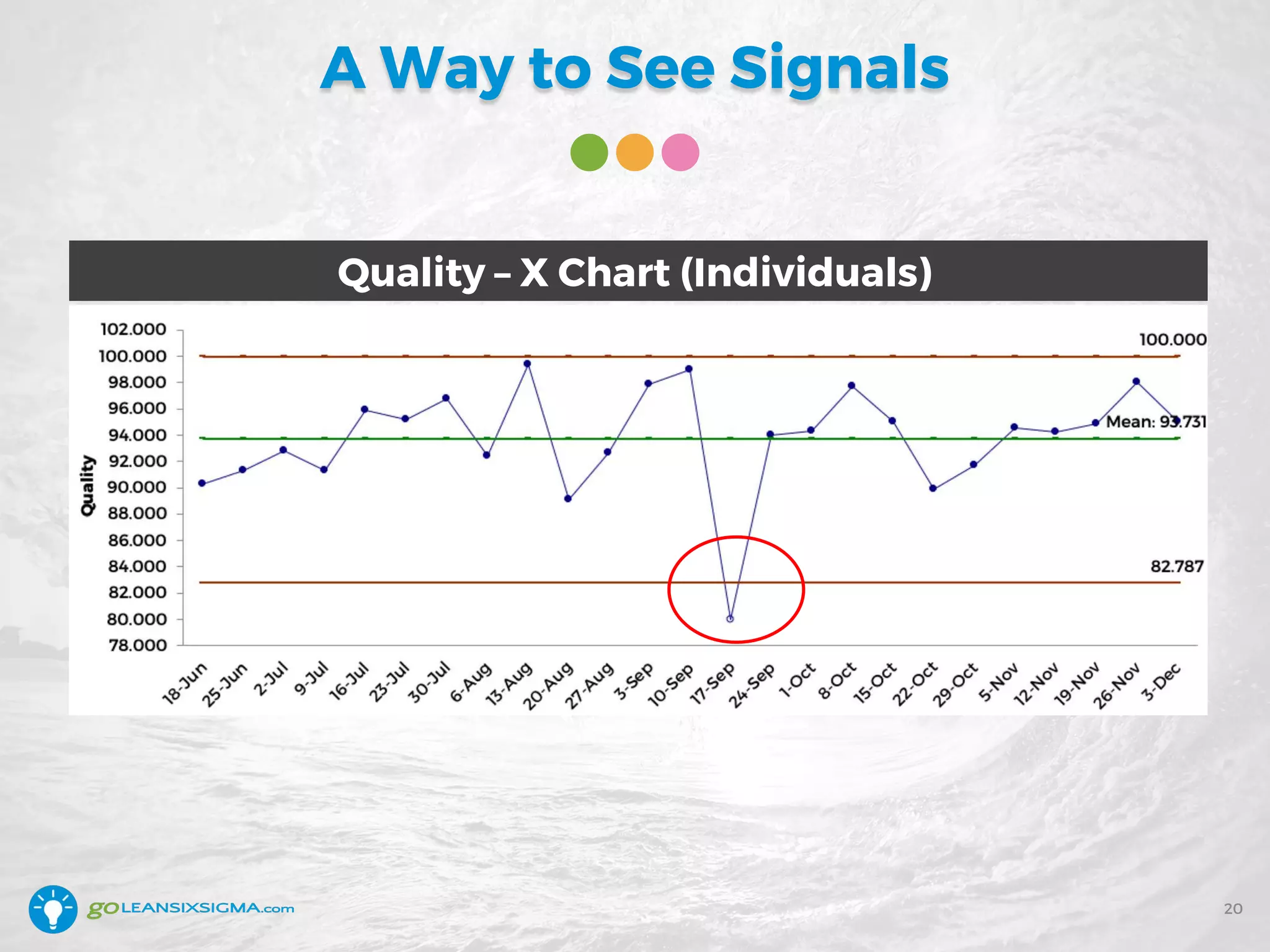

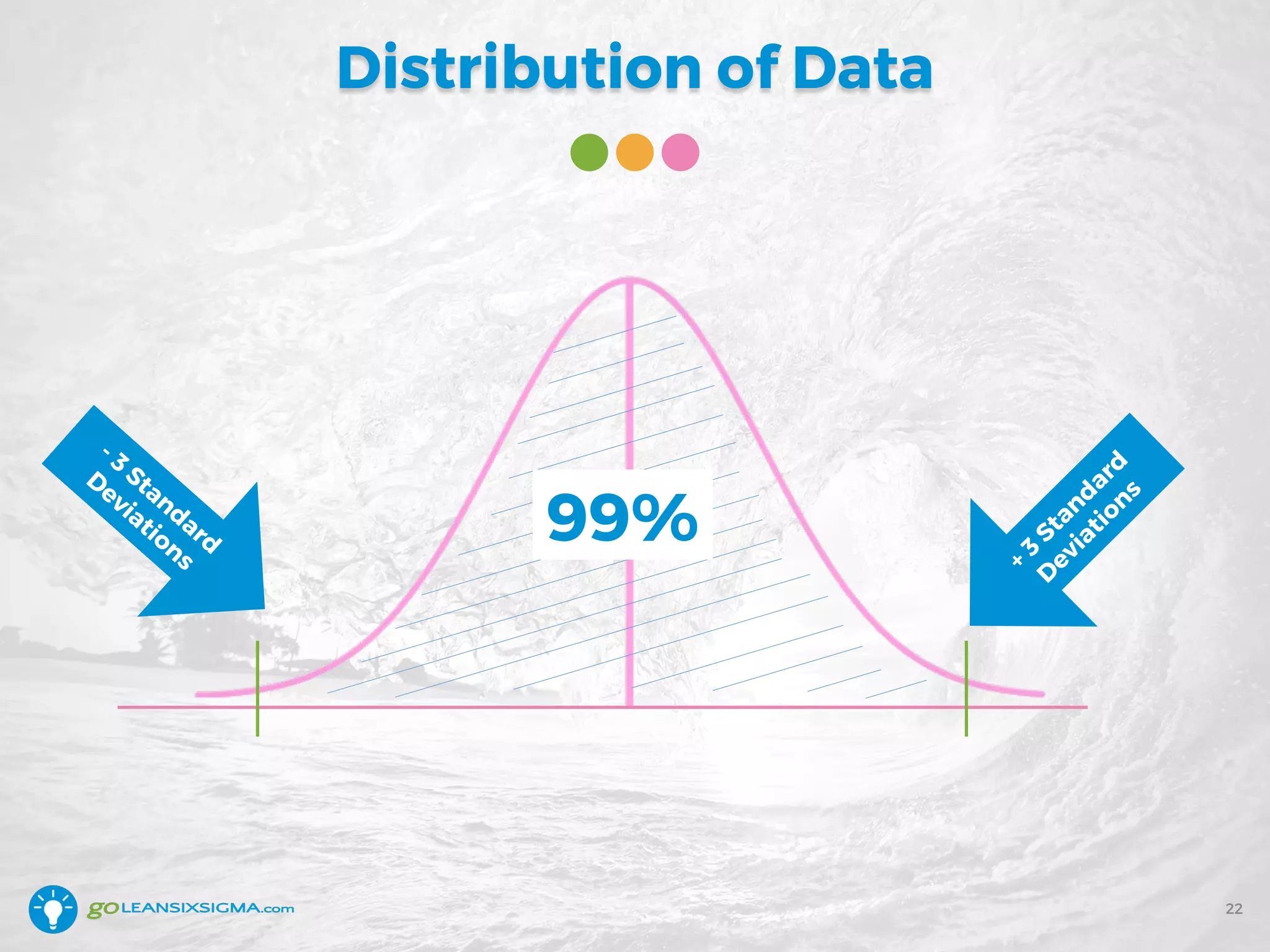

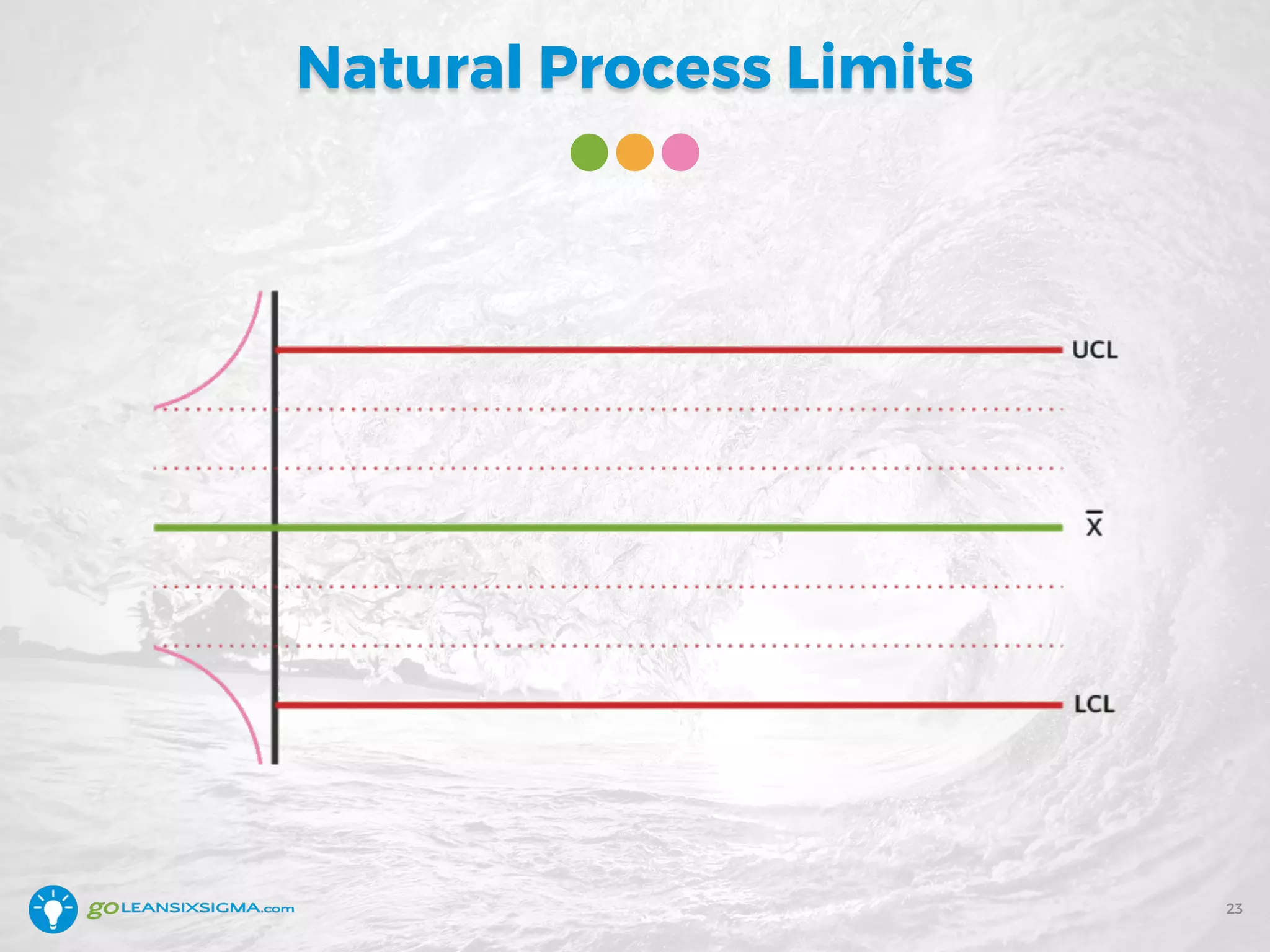

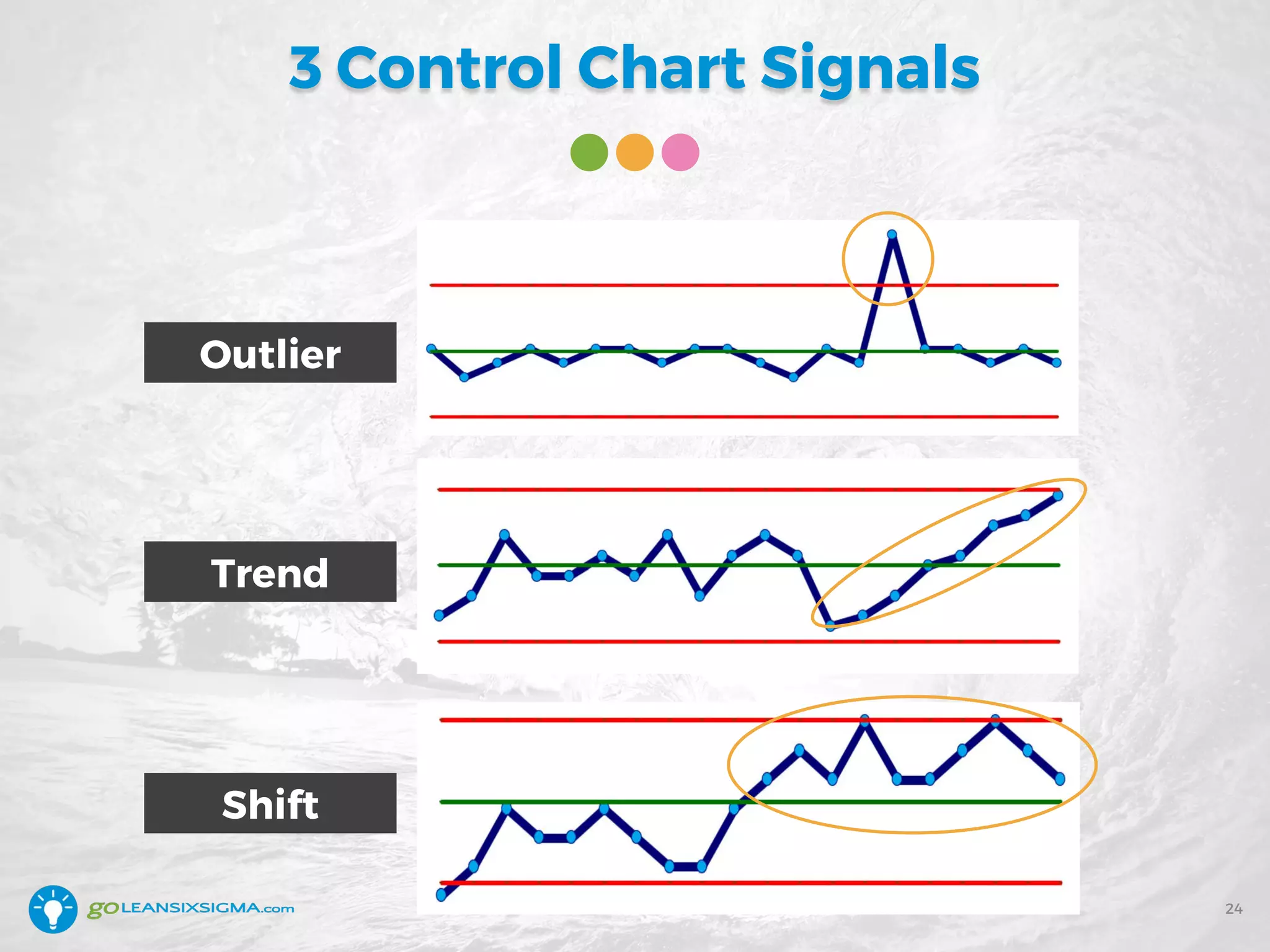

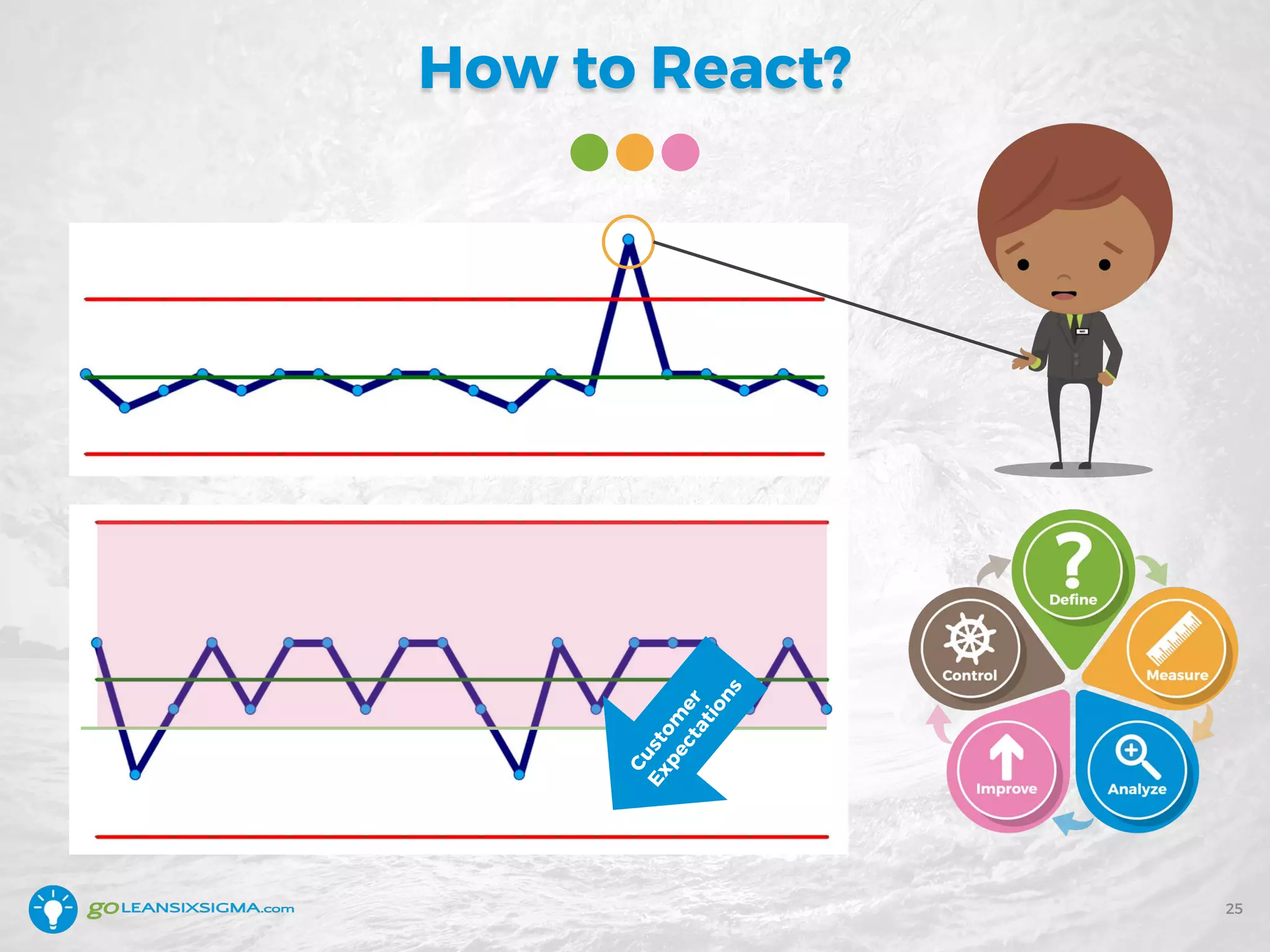

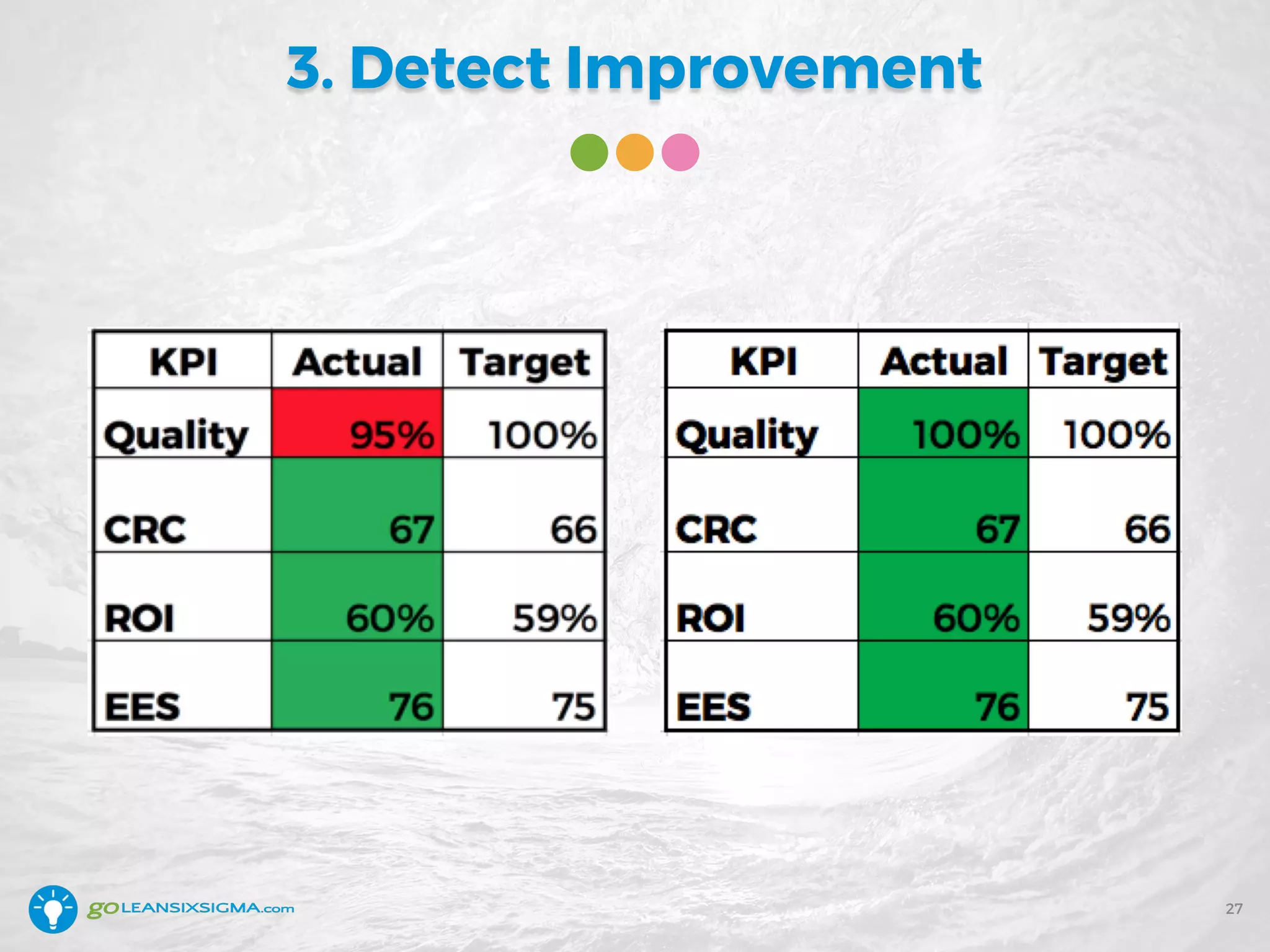

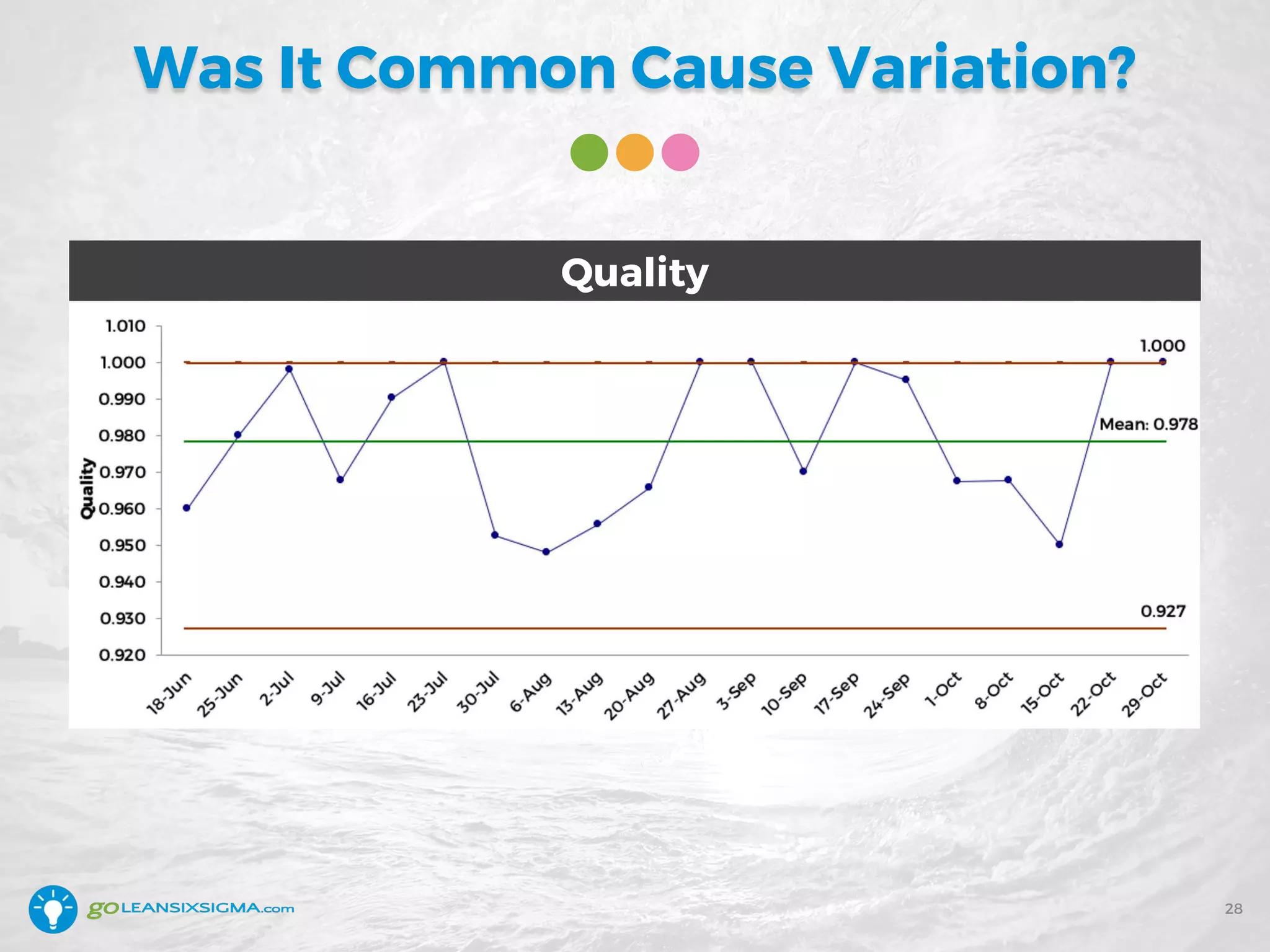

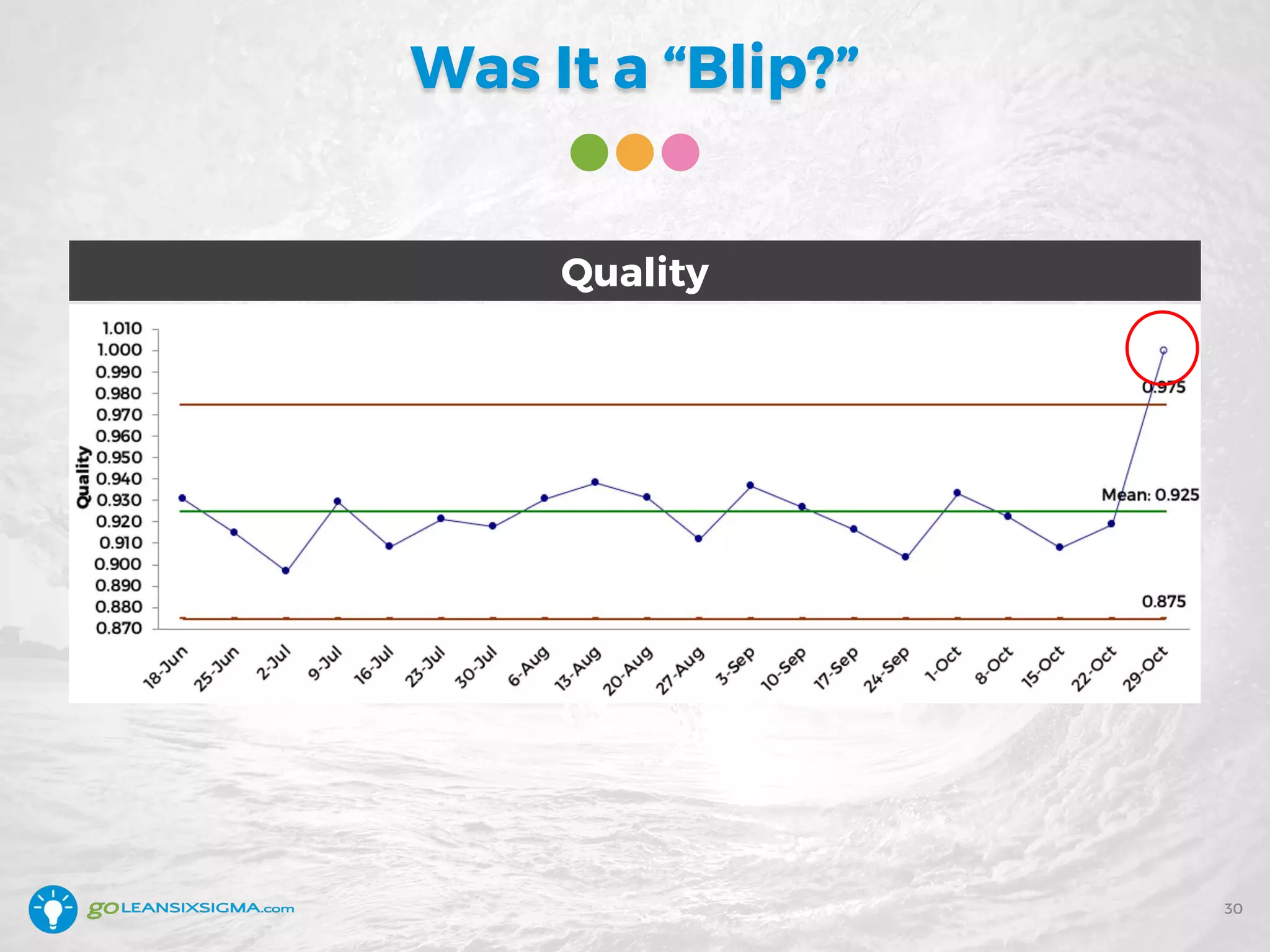

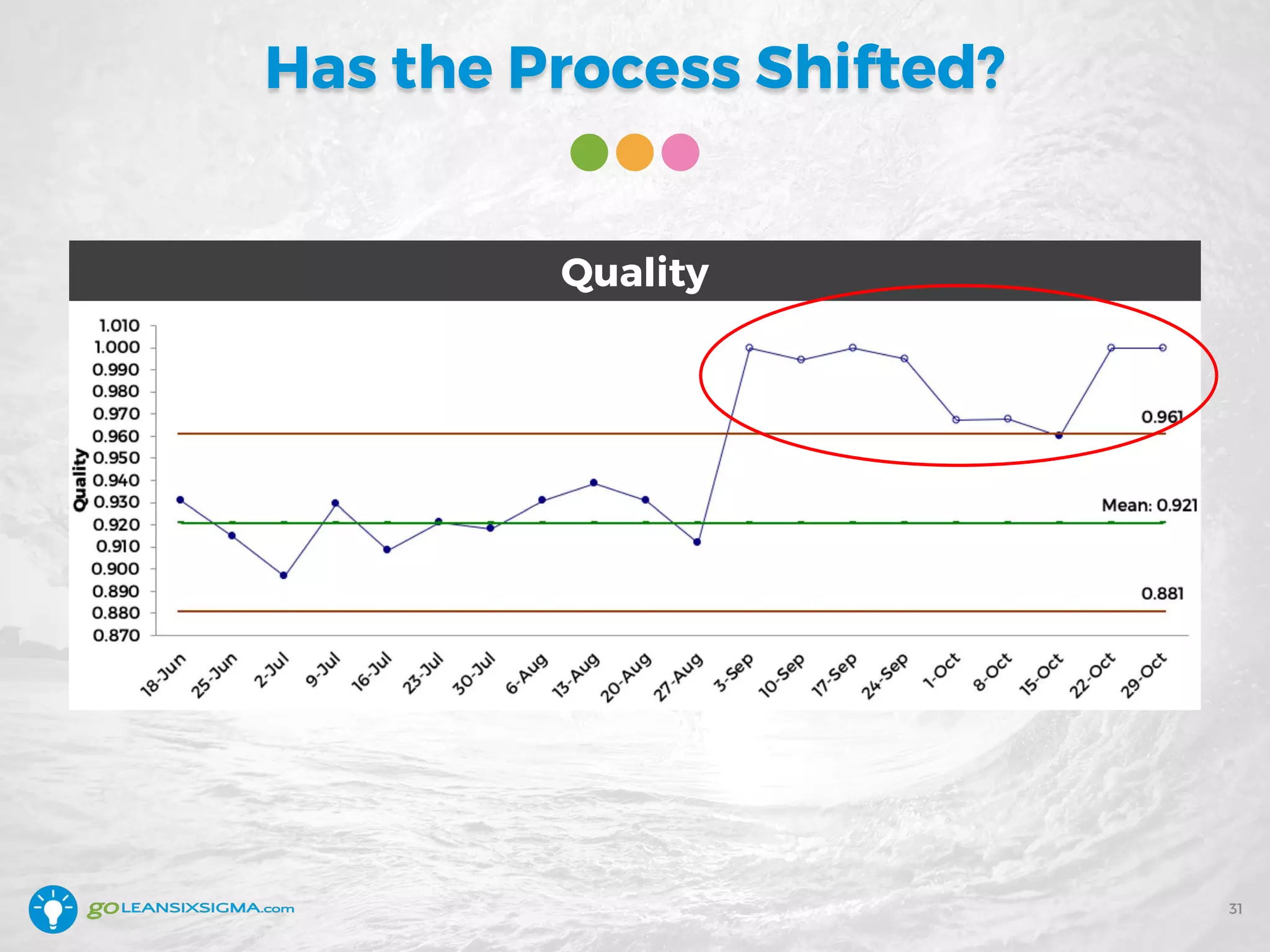

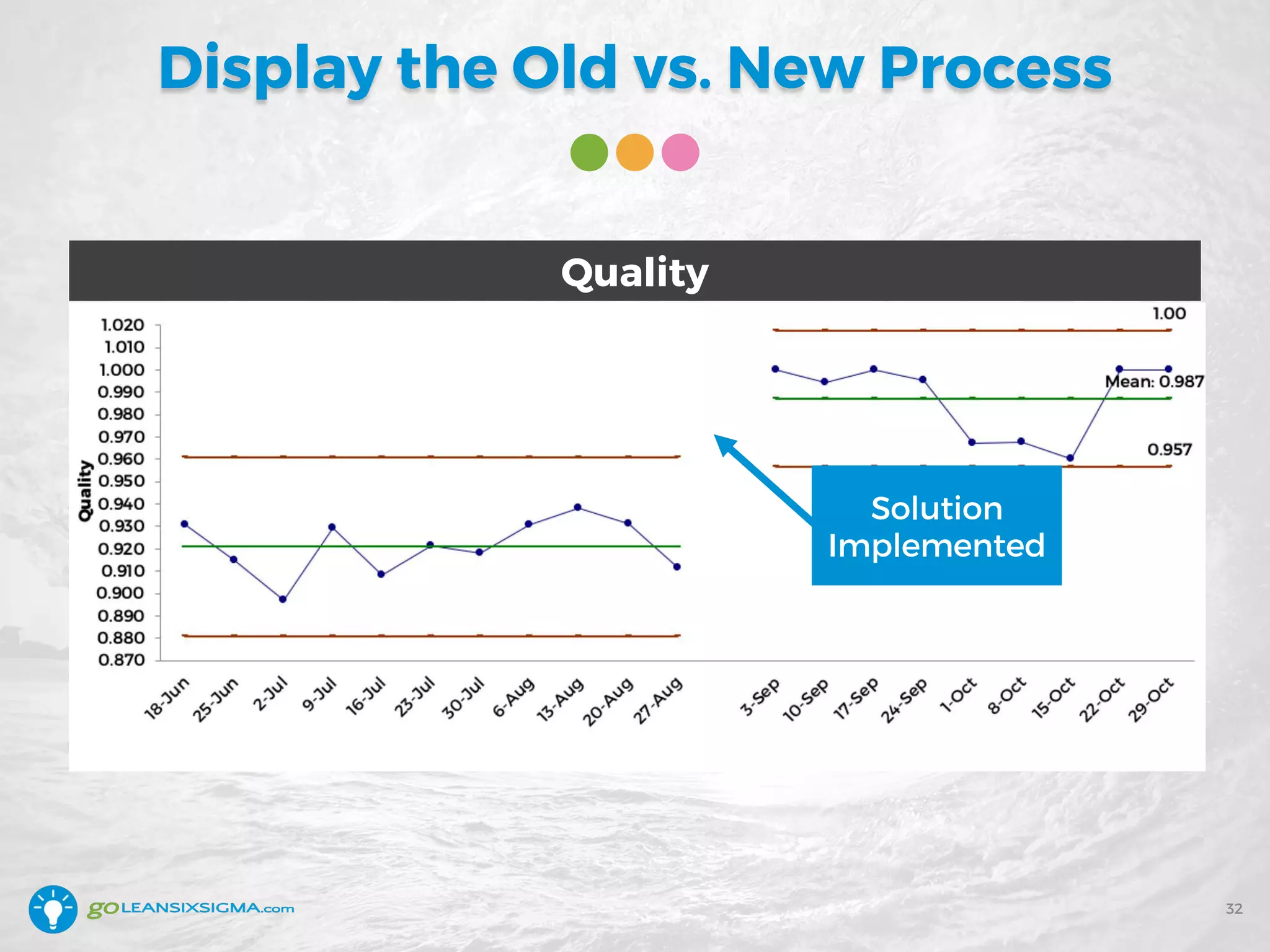

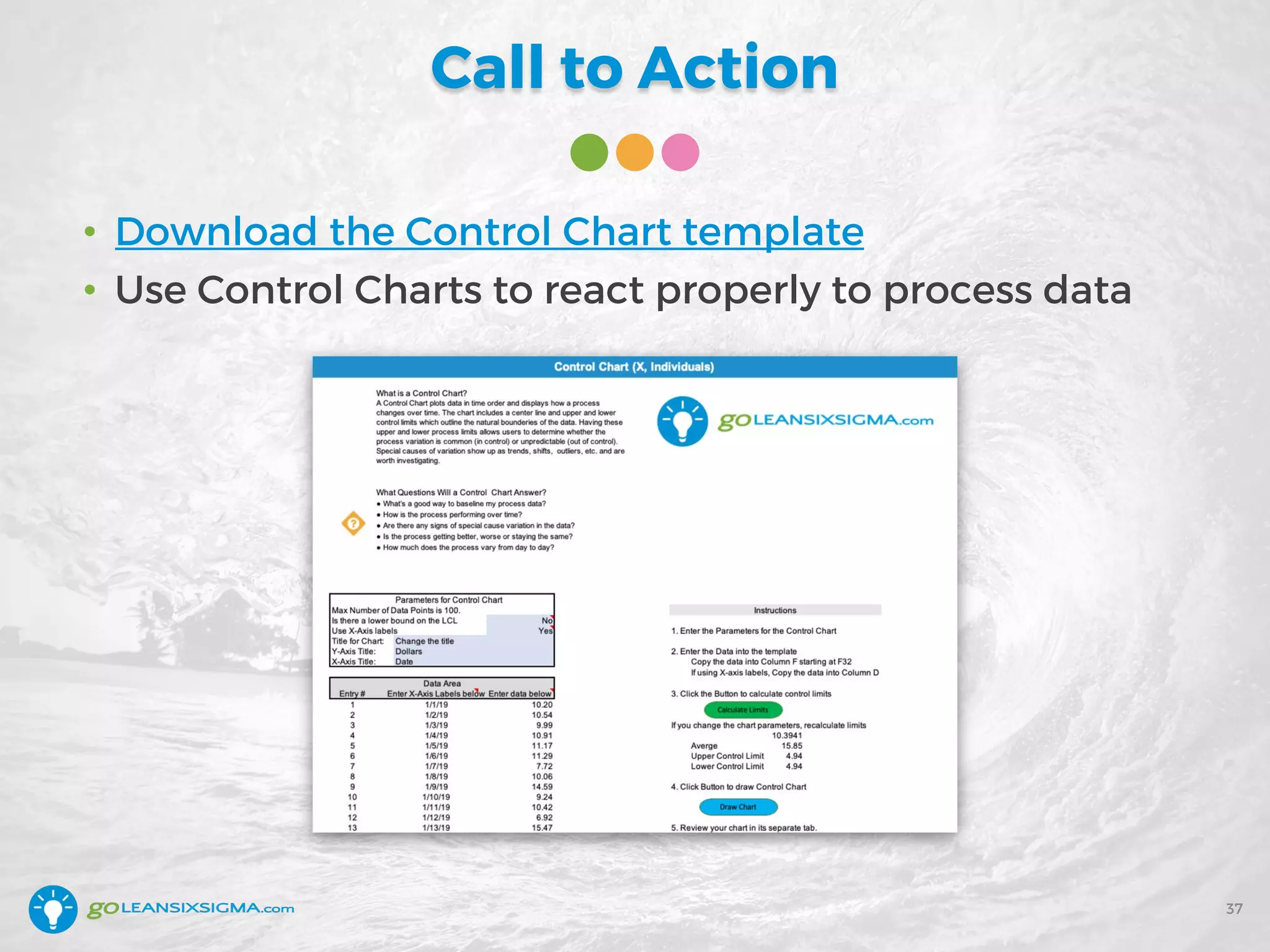

The document outlines a webinar on the use of control charts, presented by Elisabeth Swan, aimed at teaching participants how to read, utilize, and interpret control charts for process improvement. Key topics include understanding control charts, their significance, practical examples, and tips for effective use. The content emphasizes the ability to distinguish between noise and signals in data, as well as the importance of viewing data over time to detect process improvement.