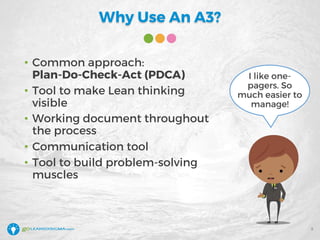

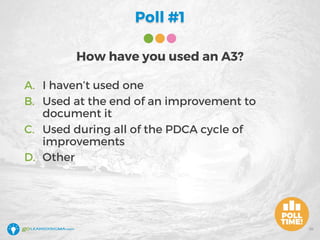

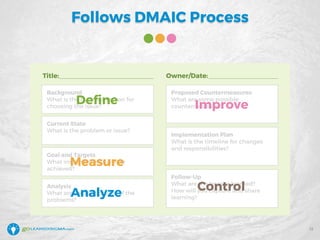

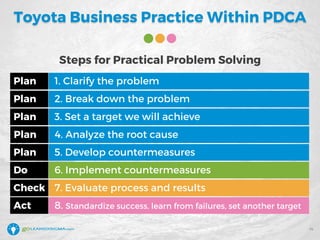

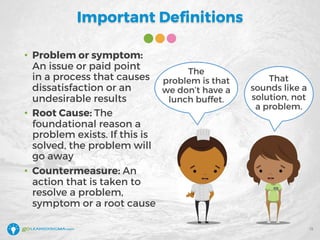

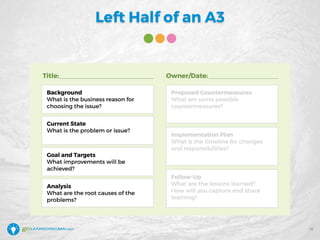

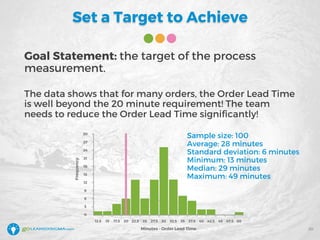

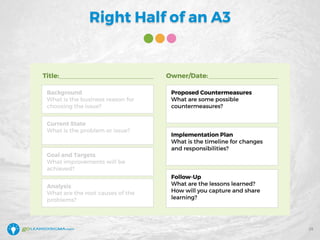

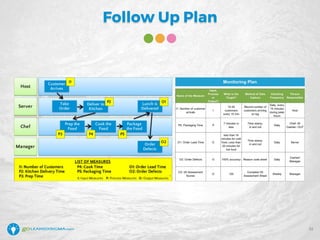

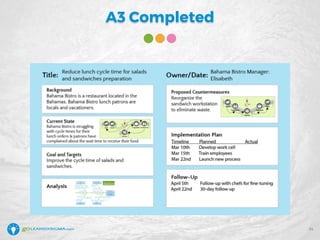

The document presents an introduction to A3 problem-solving, featuring Tracy O'Rourke as the speaker, who outlines the A3 process, its significance, and its practical applications in lean and Six Sigma methodologies. It details the steps involved in creating an A3 report, including identifying problems, analyzing root causes, implementing countermeasures, and evaluating outcomes. The session also encourages audience interaction through polls and highlights additional training resources available at goleansixsigma.com.