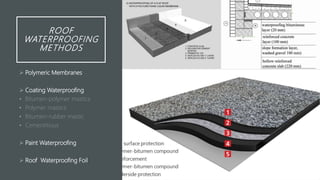

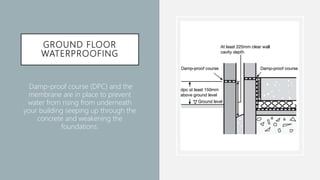

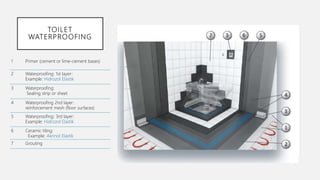

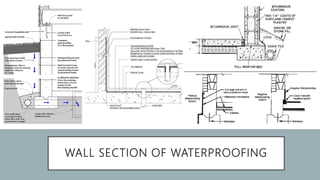

This document discusses various methods and materials for waterproofing buildings. It describes common waterproofing materials like polyurethane liquid membranes, cementitious coatings, EPDM rubber, bituminous membranes, PVC, and thermoplastics. It also outlines methods for waterproofing basements, roofs, floors, toilets, and bathrooms. These include interior/exterior drainage systems and vapor barriers. Sheet and liquid-applied membrane waterproofing options are presented along with their advantages.