Waterproofing is necessary to prevent water damage to buildings. It involves applying barrier membranes or coatings to structures. Key areas that require waterproofing include bathrooms, toilets, terraces, basements, and overhead tanks.

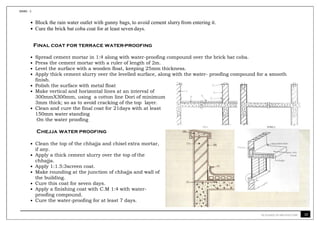

The document outlines various waterproofing methods for different building elements. It discusses preparing surfaces, applying base coats and mortars mixed with waterproofing compounds, curing layers, and finishing. Proper slope and drainage are important. Methods include cement plastering, brick bat coba, and ensuring joints are sealed to prevent water ingress. Thorough preparation and multiple curing stages help produce effective long-term waterproofing.