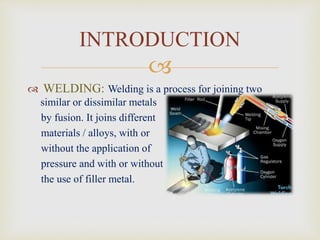

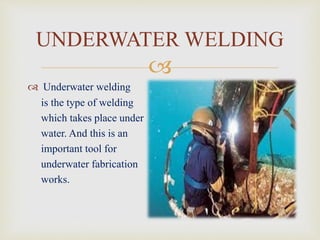

Underwater welding can be classified as wet welding or dry welding. Wet welding is performed directly in water using manual arc welding, which has advantages of lower cost but risks of cracking and poor visibility. Dry welding uses a chamber near the work area and gas metal arc welding for better quality welds and welder safety, but requires more complex equipment and has higher costs. Underwater welding is used for ship repair and construction, offshore energy structures, and other underwater fabrication work, but poses electric shock and explosion risks that require inspections.