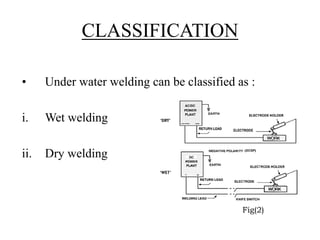

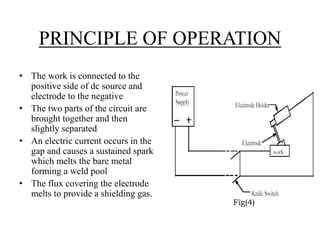

Underwater welding can be classified as either wet or dry welding. Wet welding is performed directly in water and allows for increased freedom of movement but has poorer quality welds than dry welding. Dry welding takes place inside a pressurized chamber near the work area and produces higher quality welds, most commonly using gas tungsten arc welding or gas metal arc welding processes. Underwater welding requires specialized equipment including powerful power supplies, gas manifolds, and pressurized chambers. It is used for applications like pipeline construction and repair, ship construction and maintenance, and offshore oil rig installation and repair.