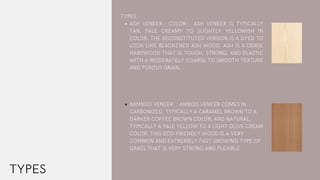

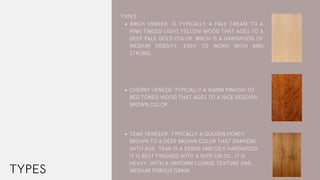

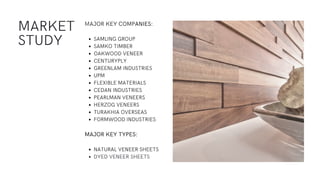

The document discusses wood veneers, including their composition, manufacturing process, types, market study, advantages/disadvantages, and applications. Veneers are thin slices of wood or bark that are glued to core panels to produce flat surfaces. They go through a process of debarking, cooking, slicing, drying, quality checking, splicing and packing. Common types include ash, bamboo, birch, cherry and teak. A market study examines key companies, sizes, thicknesses, prices and finishes. Veneers provide aesthetic wood looks at low cost and increase durability, while disadvantages include water damage susceptibility and needing maintenance. Main applications are commercial, casework and covering MDF/particleboard.