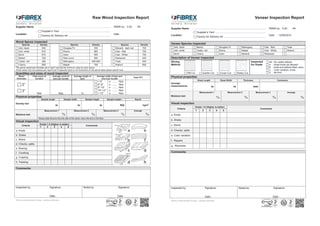

This document summarizes a wood inspection report for a supplier. It lists the species inspected and their densities. It details the quantities and sizes of wood bundles inspected, including total count, average bars per bundle, average length and width. It reports on physical property tests for density and moisture. It provides a visual inspection grading of the wood on criteria like knots, shakes, wanes and splits.