Timber, also known as wood, can be used for many structural and engineering purposes. Some key points covered in the document include:

- Timber has advantages such as availability, salvage value, ease of transport and joining.

- It has many uses including for railway sleepers, roof trusses, furniture, formwork, and packaging.

- Timber comes in various market forms depending on its size, including battens, logs, planks, boards, and poles.

- Veneers are thin wood sheets used to make plywood, which layers veneers with perpendicular grain directions to increase strength.

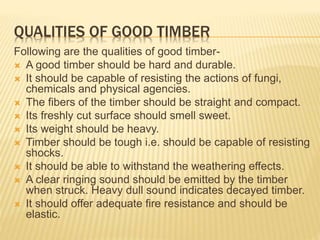

- Different types of timber have varying properties making some more suitable for uses like construction