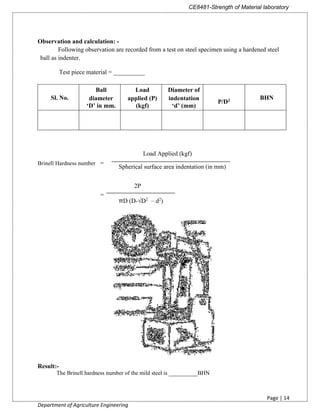

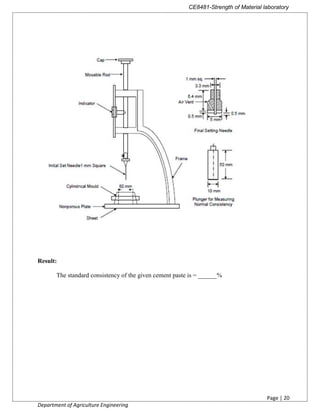

This document is a laboratory manual for the Strength of Materials course for B.E. Agriculture Engineering students at Sri Shanmugha College of Engineering and Technology. It outlines laboratory guidelines, objectives, a list of experiments including tensile, compression, and impact tests, and procedures for conducting these tests on various materials. The manual aims to equip students with practical knowledge and skills in testing materials and their characteristics under different forces.