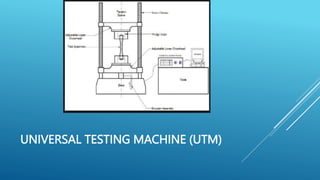

The document discusses the deformation of metals, describing how materials react to external loads through deformation and the associated internal stress. It covers the classification of force systems, definitions of load, stress, and strain, as well as an introduction to composite bars. Additionally, it outlines the procedure for performing tensile tests to assess the mechanical behavior of materials using a universal testing machine.