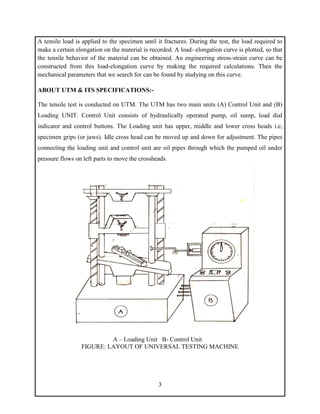

The document describes procedures for conducting a tensile test to determine properties of a ductile material specimen. Key steps include measuring the original dimensions of the specimen, clamping it in a universal testing machine and applying a tensile load until fracture. Load and extension readings are recorded to plot stress-strain curves and calculate properties like yield strength, tensile strength, elongation and Young's modulus. The test is aimed at understanding tensile behavior, stress-strain relationships and evaluating mechanical properties of engineering materials.

![1

D.Y. PATIL COLLEGE OF ENGINEERING

AKURDI, PUNE-411044

Department of Mechanical Engineering

SOLID MECHANICS [202042]

SE MECH [2019 PAT]

TENSION TEST ON DUCTILE

MATERIAL](https://image.slidesharecdn.com/1-231018050541-568c5bd0/85/1-SM_LAB_TENSION_TEST_MS-pdf-1-320.jpg)

![9

Sample Calculations:-

A. Yield Stress =

Yield Load

Original C/S Area

=

B. Ultimate TensileStrength =

Maximum tensile load

Original C/S Area

C. Young’sModulus E = Slope ∗ (𝟏/𝟎. 𝟎𝟏) ∗ L/A = ___________GPa

[Note: Here Length of the specimen between the grips (End Markings on Specimen)

=______mm]

D. Percentage Elongation =

Final length (at fracture) – original length

Original length

=

E. Percentage Reduction in area =

Original area – Area at fracture

Original area

=](https://image.slidesharecdn.com/1-231018050541-568c5bd0/85/1-SM_LAB_TENSION_TEST_MS-pdf-9-320.jpg)