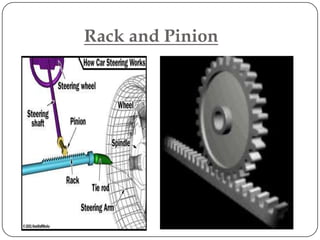

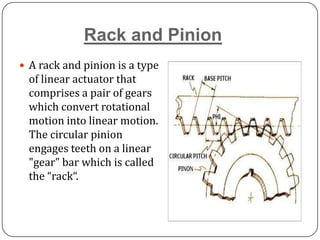

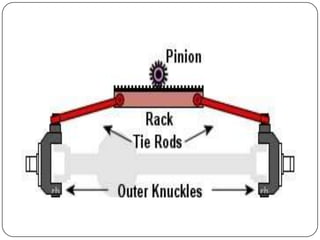

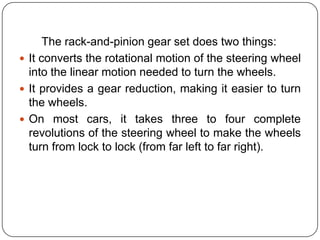

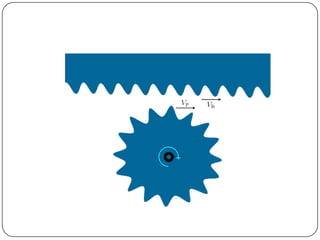

The document describes rack and pinion gears. A rack and pinion system uses two gears - a pinion gear which is circular, and a rack gear which is flat. The pinion gear engages with the teeth on the rack gear to convert rotational motion into linear motion or vice versa. Rack and pinion systems are commonly used in steering systems in cars, where the rotation of the steering wheel is converted to linear motion that turns the wheels. The key components of a rack and pinion steering system are the pinion, rack, inner ball joints, tie rods and rubber bellows.