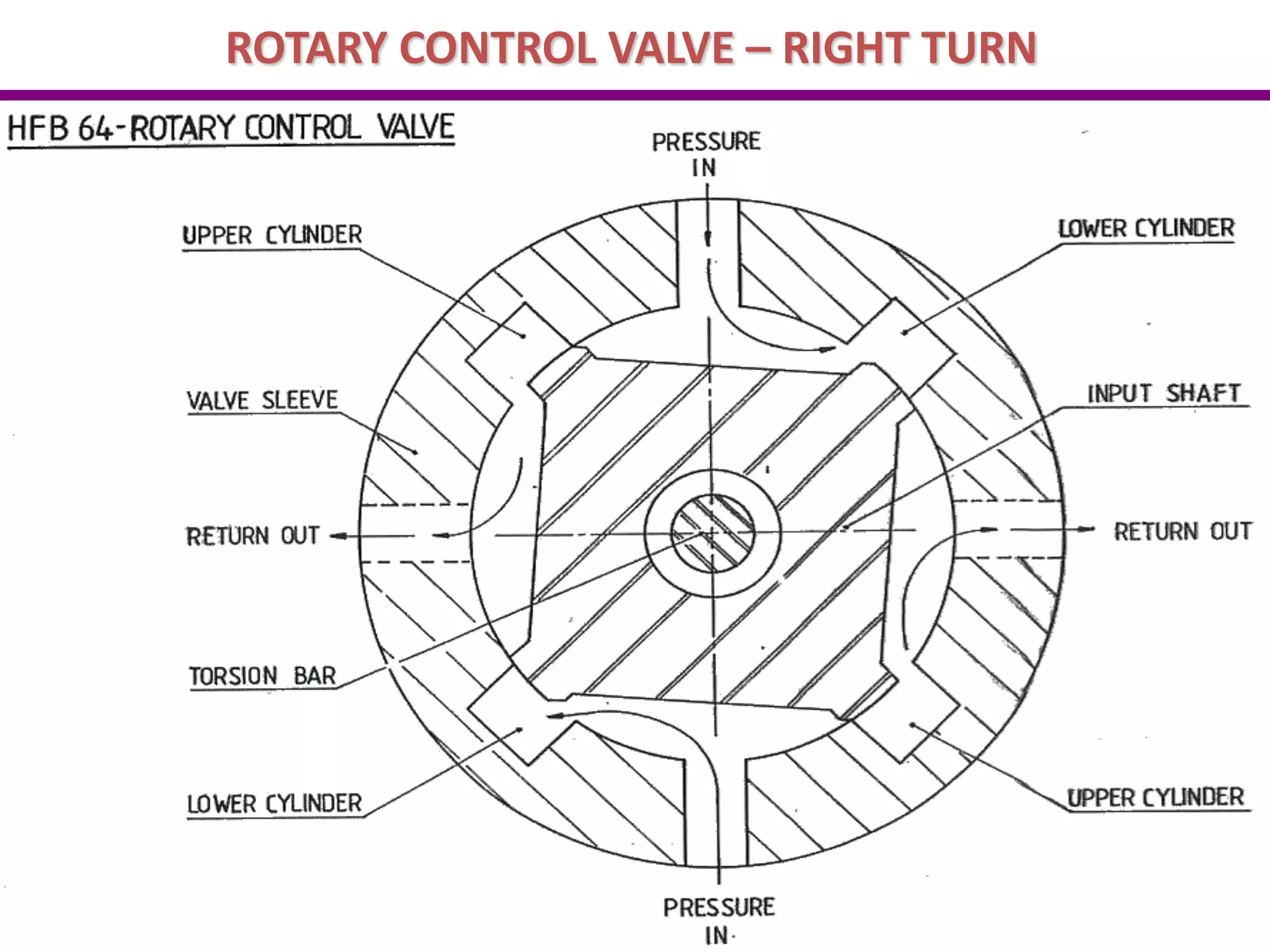

The document discusses the steering system of an automobile. It begins by introducing the steering system and describing how it converts rotational movement of the steering wheel into angular turns of the front wheels. It then discusses specifics of power steering systems, including their layout and components. It provides details on the Rane power steering system used in the vehicle, including its components like the gear box and control valve. It describes how the system functions during left and right turns through the movement of the control valve and fluid flow.