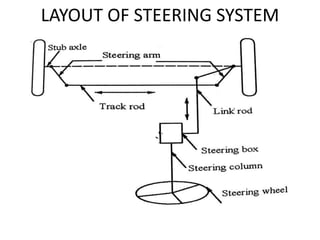

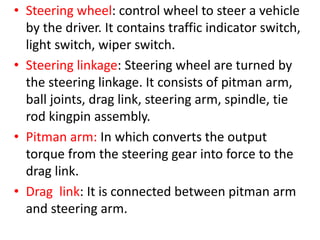

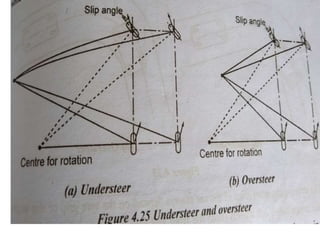

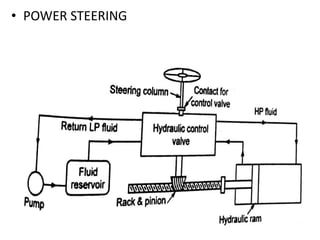

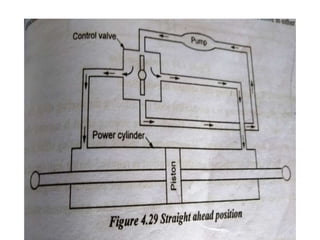

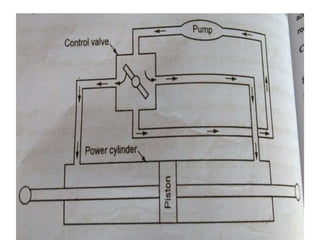

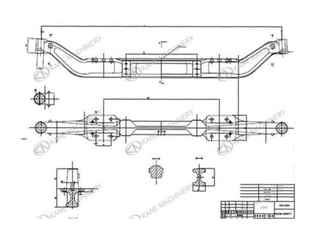

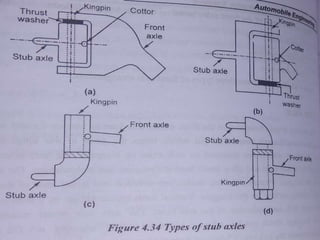

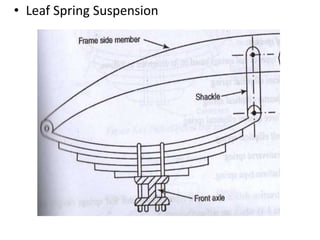

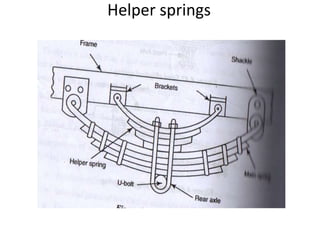

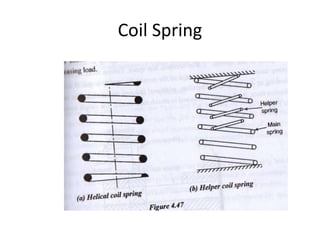

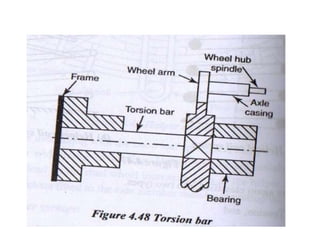

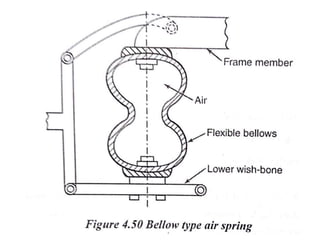

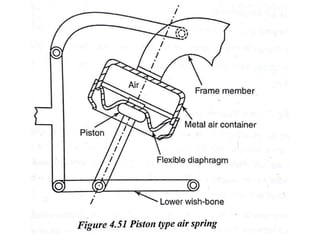

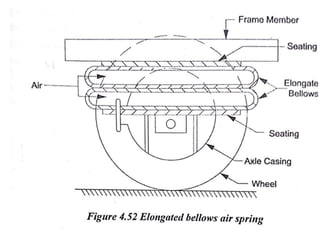

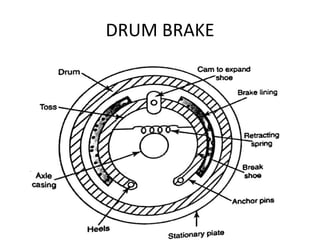

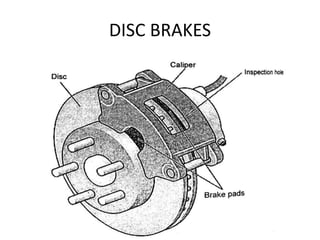

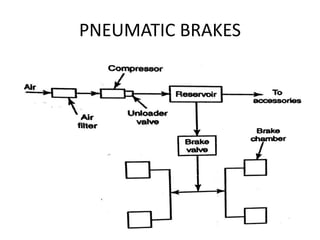

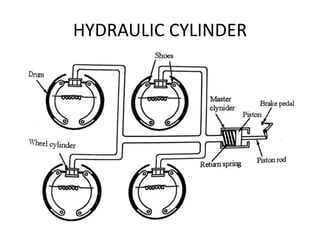

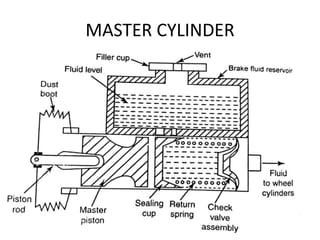

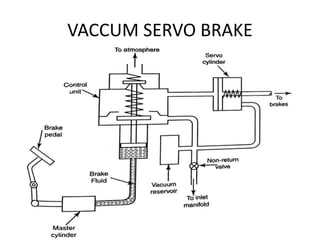

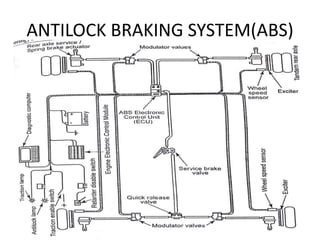

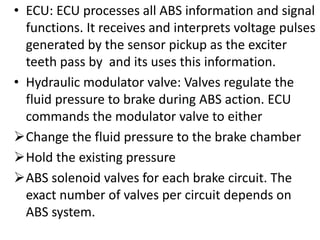

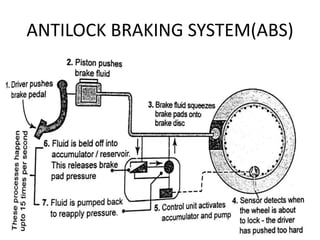

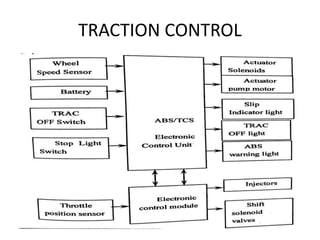

The document provides information on steering, brakes, and suspension systems. It describes the layout and function of key steering system components like the steering wheel, linkage, and gear. It discusses suspension types like leaf springs, coil springs, and torsion bars. It also covers drum and disc brakes, as well as pneumatic and hydraulic brake systems. Antilock braking systems and traction control are introduced.