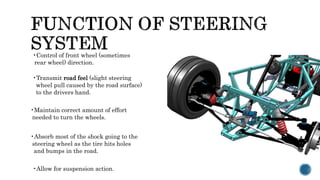

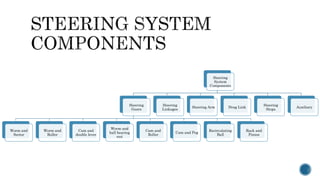

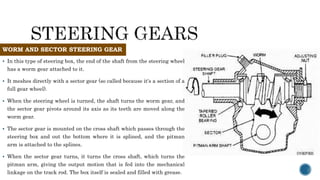

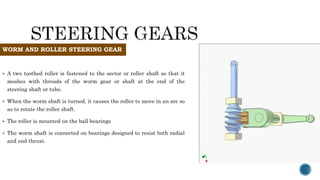

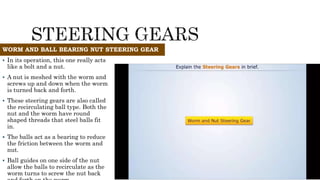

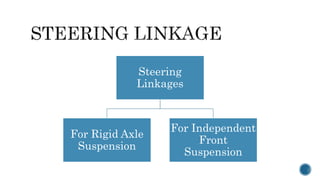

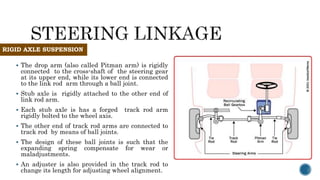

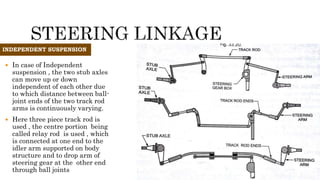

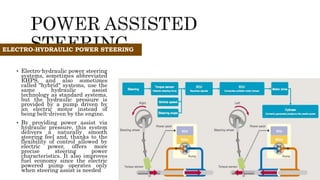

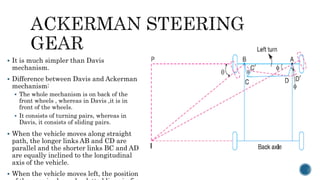

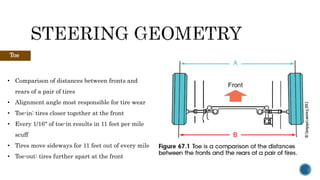

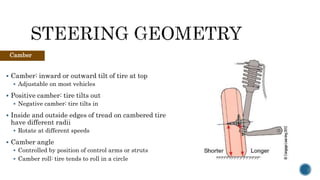

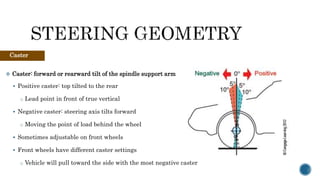

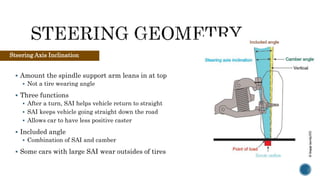

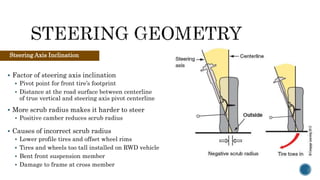

The document discusses the key components and functions of an automobile steering system. It describes common types of steering gears like worm and sector, worm and roller, and rack and pinion. It also outlines steering linkages for rigid axle and independent suspensions. Power steering systems like electric, hydraulic, and electro-hydraulic are introduced. Finally, it covers steering geometry angles including toe, camber, caster, steering axis inclination, and turning radius.