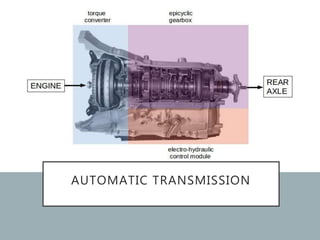

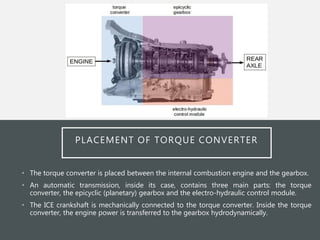

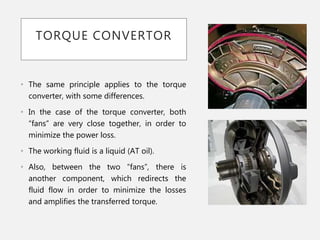

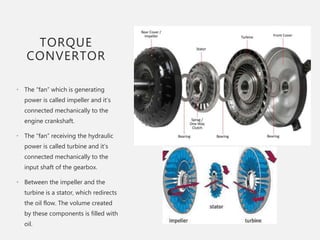

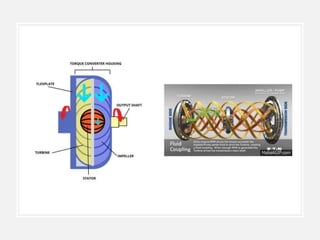

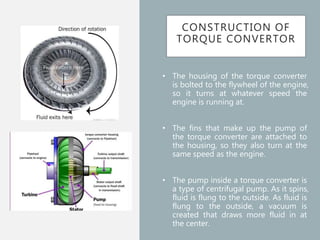

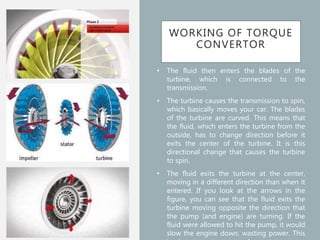

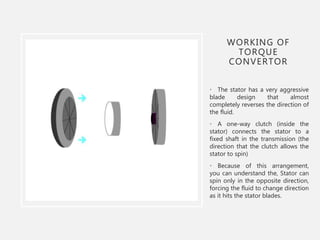

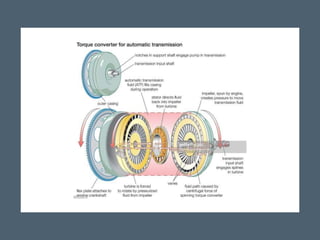

The document discusses the torque converter and its role in automatic transmissions. It explains that the torque converter uses transmission fluid to transfer power from the engine to the transmission hydrodynamically. The torque converter contains an impeller connected to the engine, a turbine connected to the transmission input shaft, and a stator that redirects the fluid flow to multiply torque. The automatic transmission also contains a planetary gearset and hydraulic controls to shift gears without a clutch pedal.