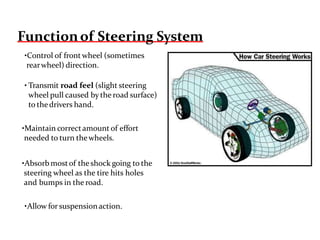

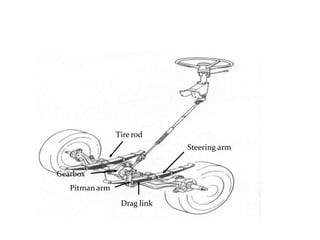

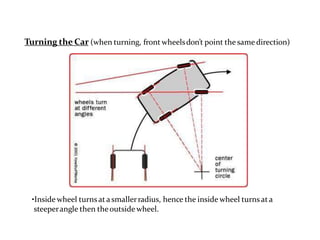

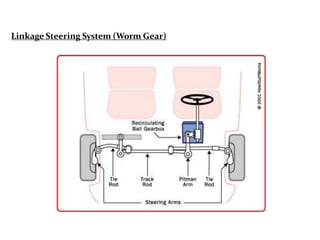

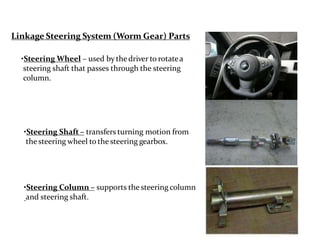

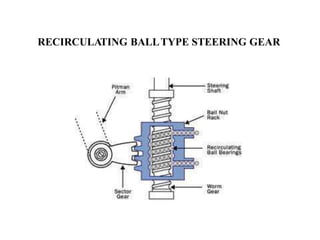

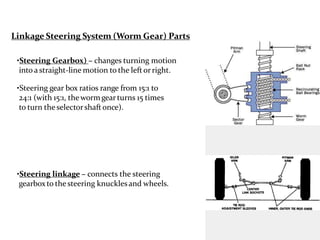

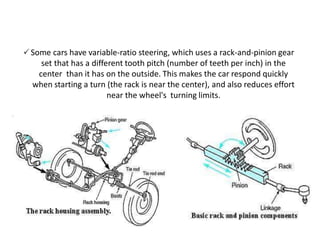

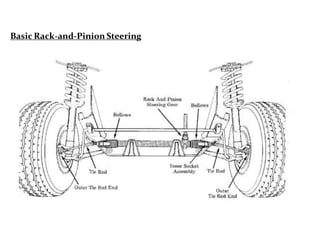

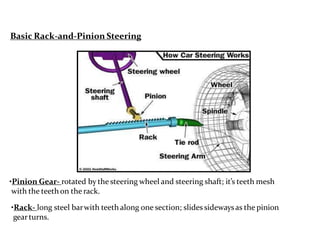

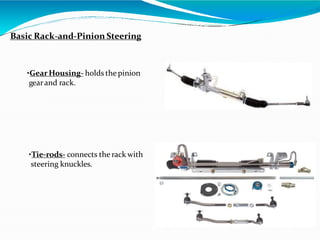

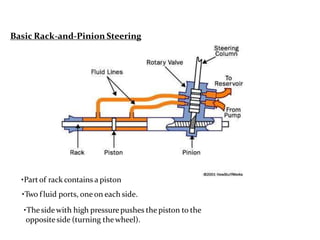

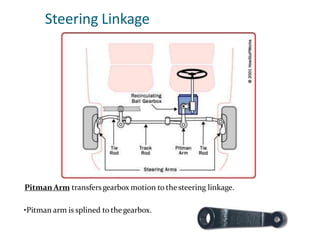

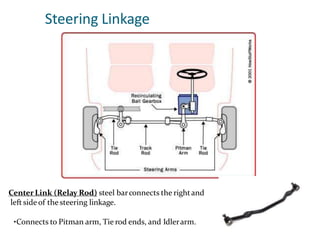

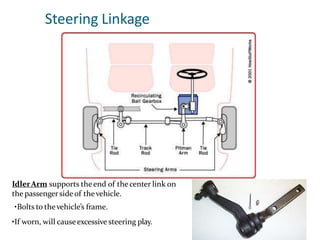

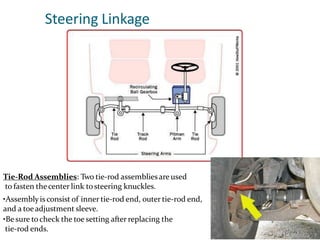

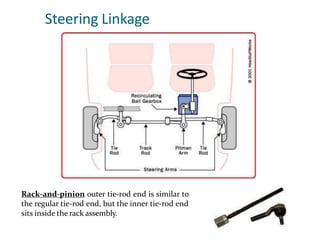

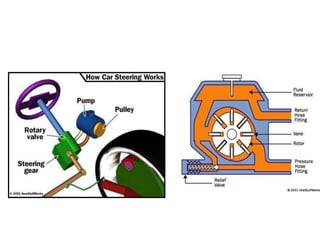

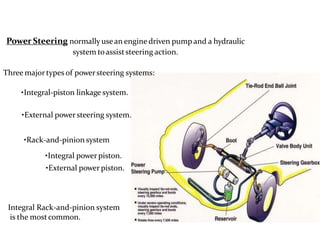

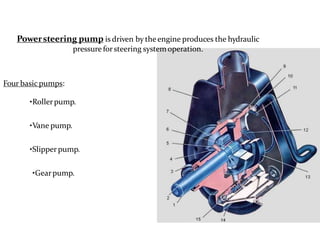

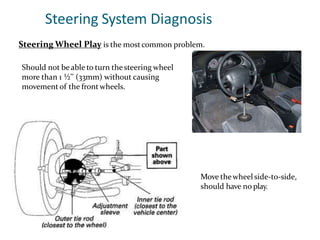

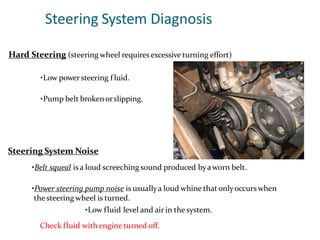

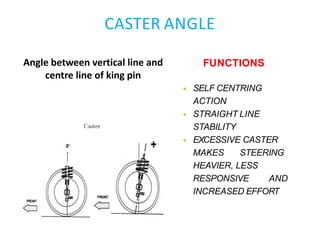

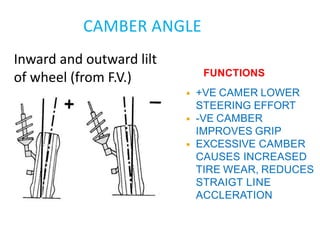

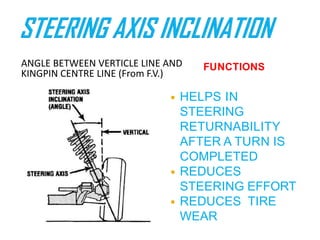

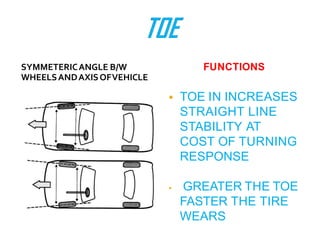

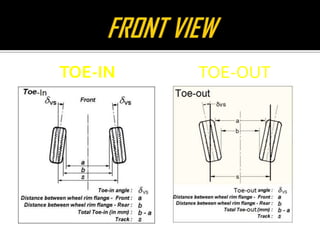

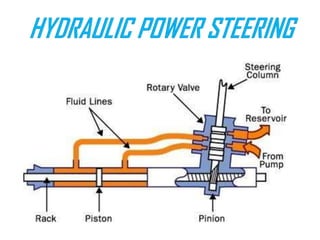

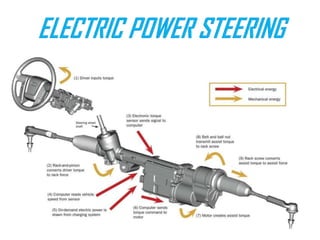

The document discusses various components that make up automobile steering systems. It describes common steering system types including recirculating ball steering gears, rack-and-pinion steering, and hydraulic power steering. It also discusses steering linkages, alignment angles, and power steering diagnosis. The purpose of a steering system is to transfer the motion of the steering wheel to the front wheels to allow the vehicle to follow the desired direction.