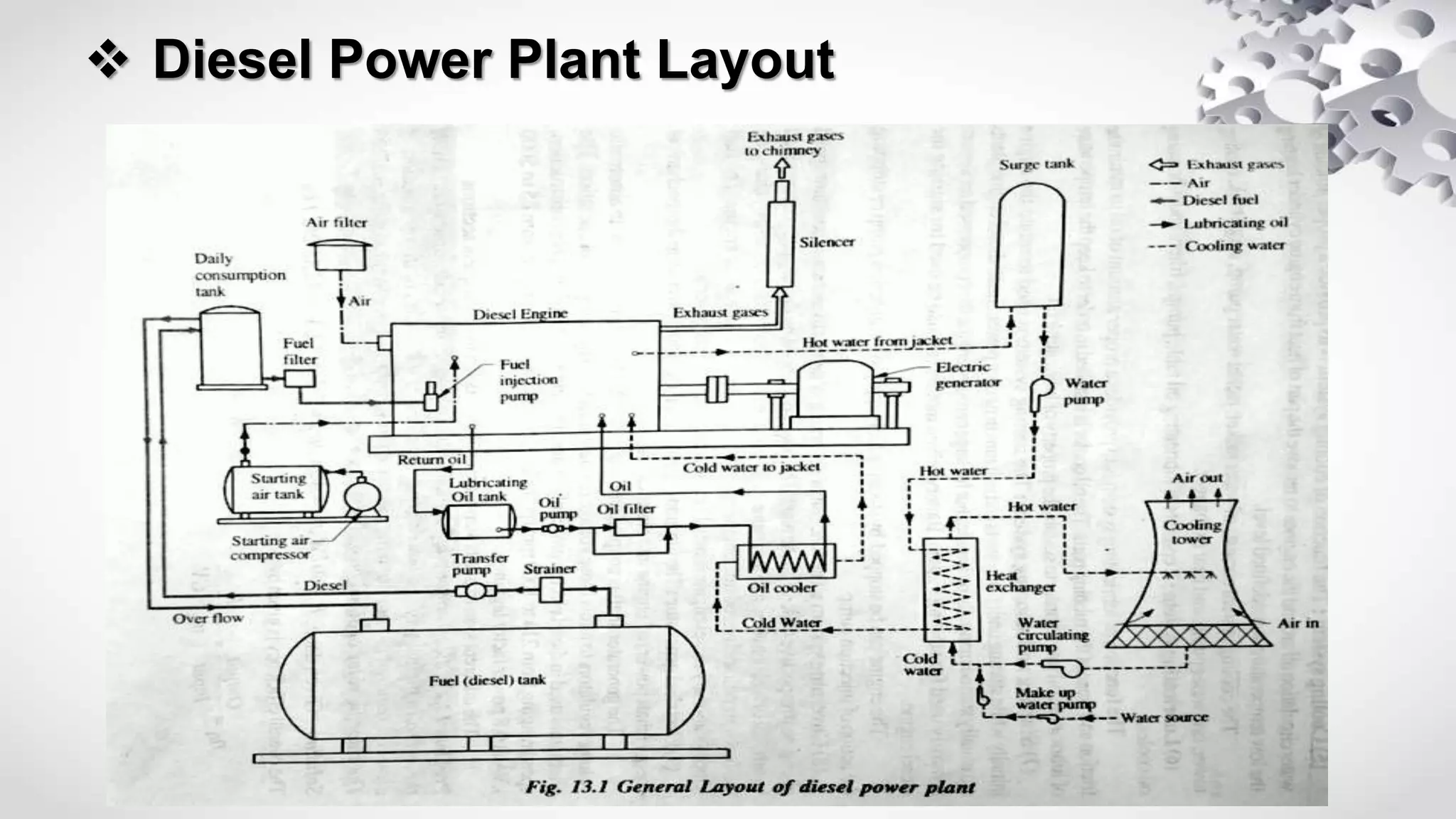

Diesel power plants use diesel engines as the prime mover to generate electricity. They are suitable for small to medium outputs up to 5MW. The key components of a diesel power plant include the diesel engine, fuel system, intake system, exhaust system, cooling system, lubricating system, starting/stopping system, and governing system. The generator converts the mechanical energy from the engine into electrical energy. Diesel power plants have advantages such as small size, quick start-up, and lower capital costs compared to steam plants. However, their operating costs are higher due to fuel costs and they are limited to outputs below 15MW.