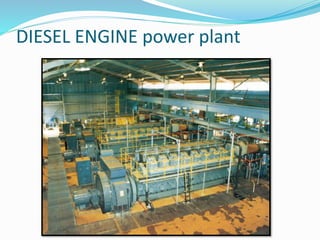

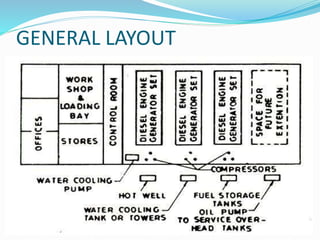

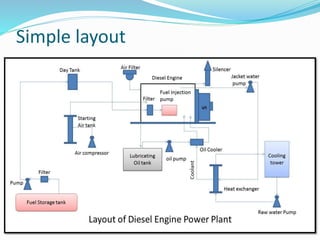

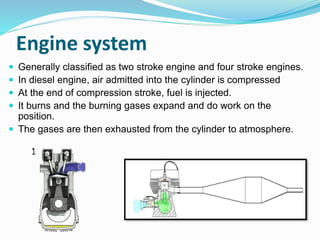

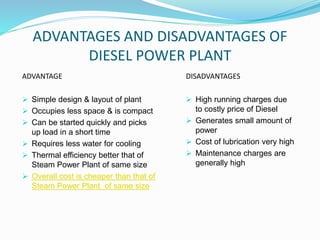

This document discusses the applications and layout of a diesel power plant. It describes how diesel power plants can be used as central stations for small or medium power supplies, as stand-by plants for hydroelectric or steam plants, and as peak load plants. It also notes their use for mobile power generation. The major systems of a diesel power plant are then outlined, including the engine, starting, lubrication, fuel, air, cooling, exhaust, and governing systems. Advantages like compact size and quick start up are contrasted with disadvantages like high fuel and maintenance costs.