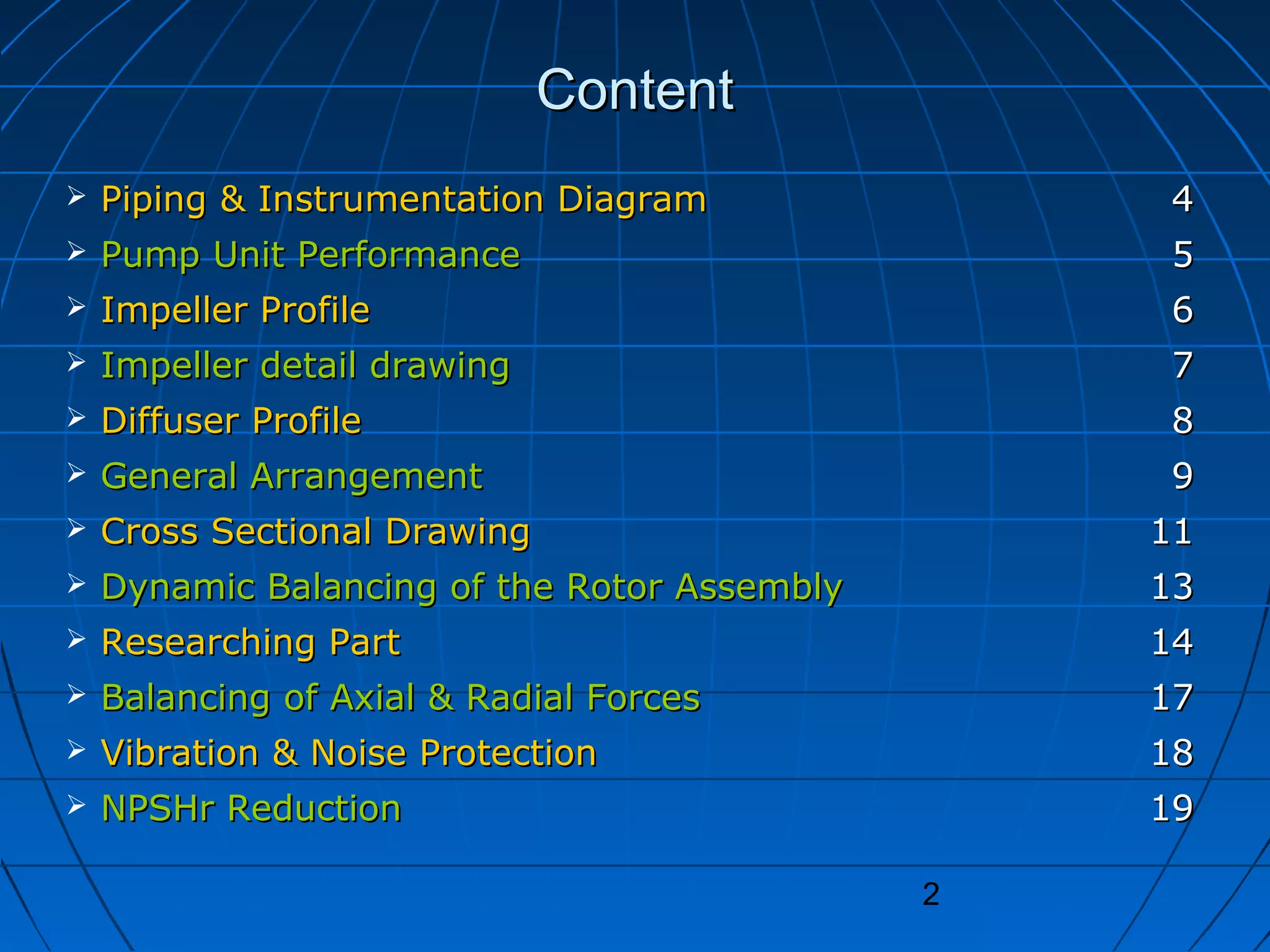

The document discusses the design of a low-noise and vibration submarine ballast drainage centrifugal pump. It describes the pump components like the impeller, diffuser, and axial-vortex stage to reduce noise and vibration. It also covers balancing radial and axial forces on the rotor, manufacturing methods like casting and machining, and conclusions about controlling noise/vibration, reducing costs, and improving reliability and maintenance.