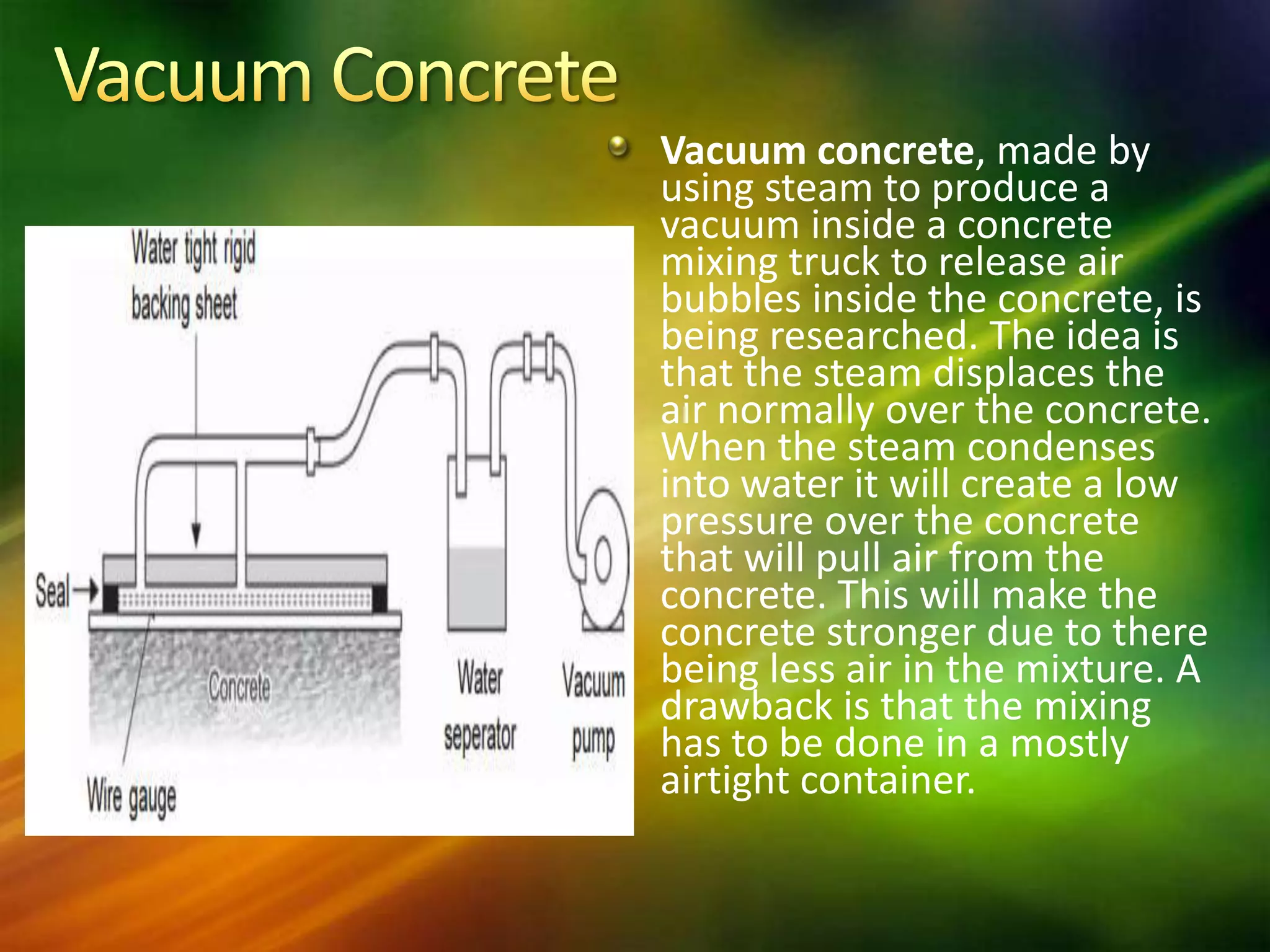

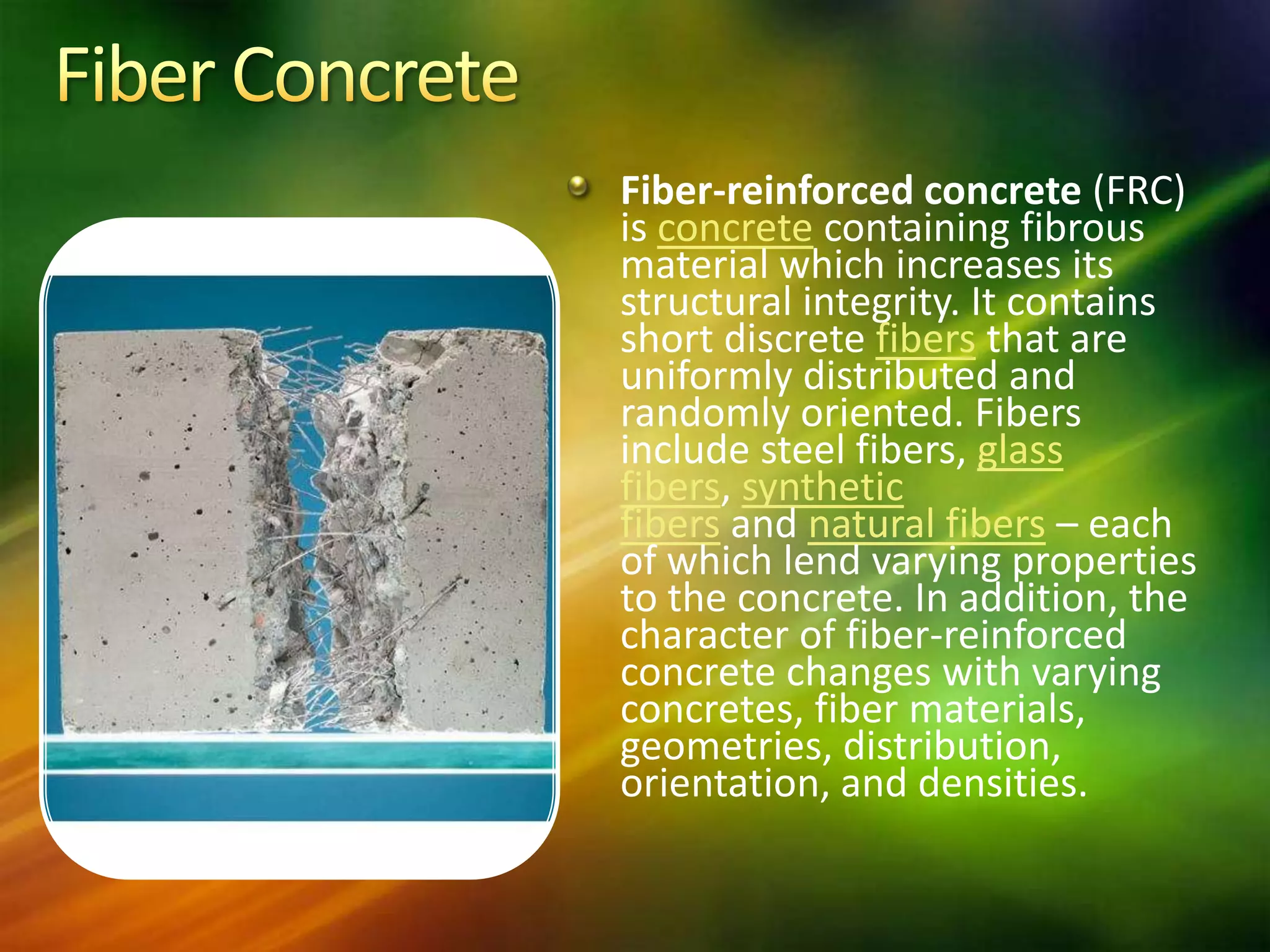

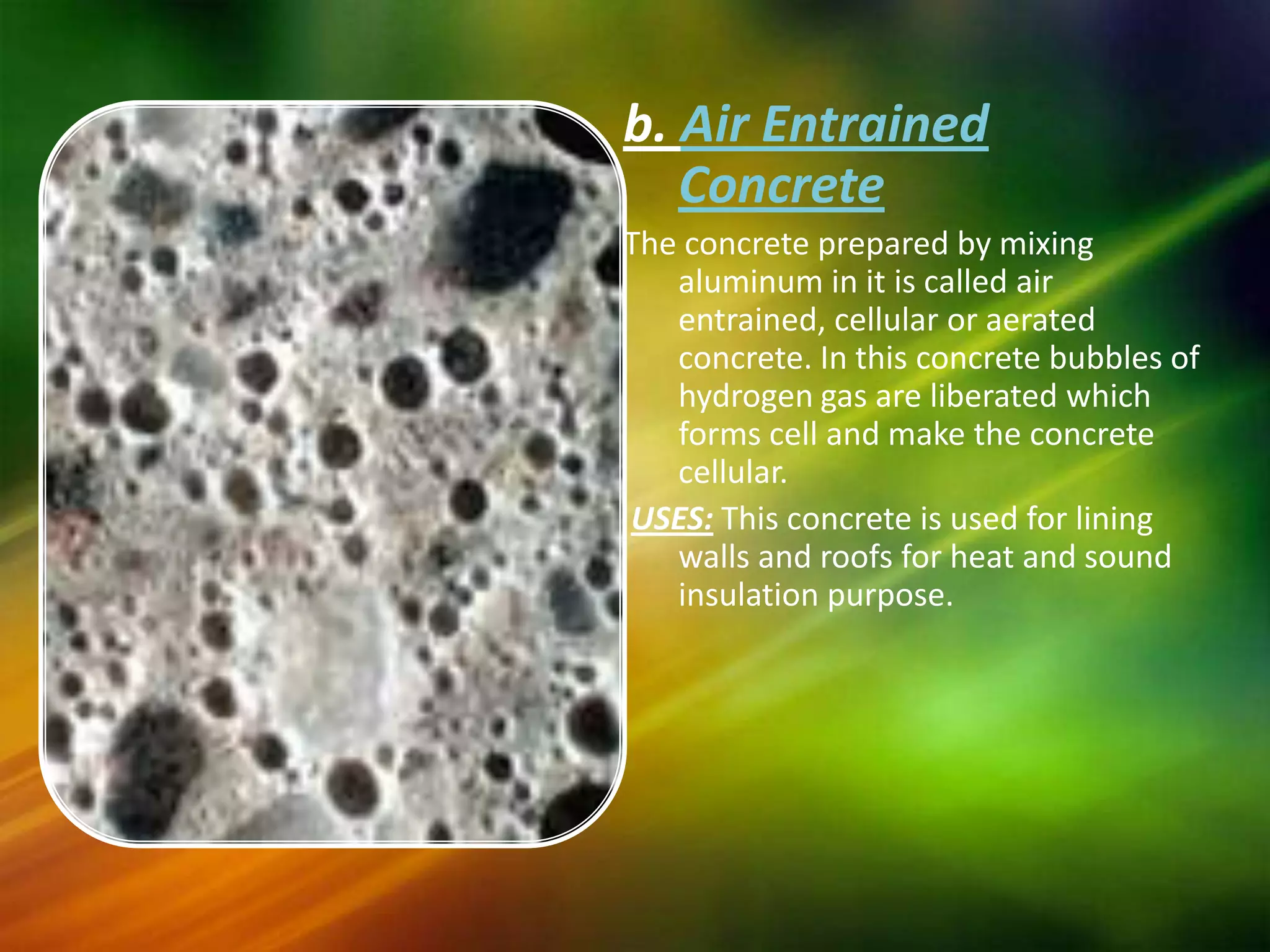

The document discusses various types of concrete, including ready mix, vacuum, shotcrete, ferrocement, fiber reinforced, polymer, air entrained, and lightweight concrete. Each type has unique properties and applications ranging from construction and repair work to insulation. The evolution of ready mix concrete since its inception in the 1930s and ongoing research into vacuum concrete are also highlighted.