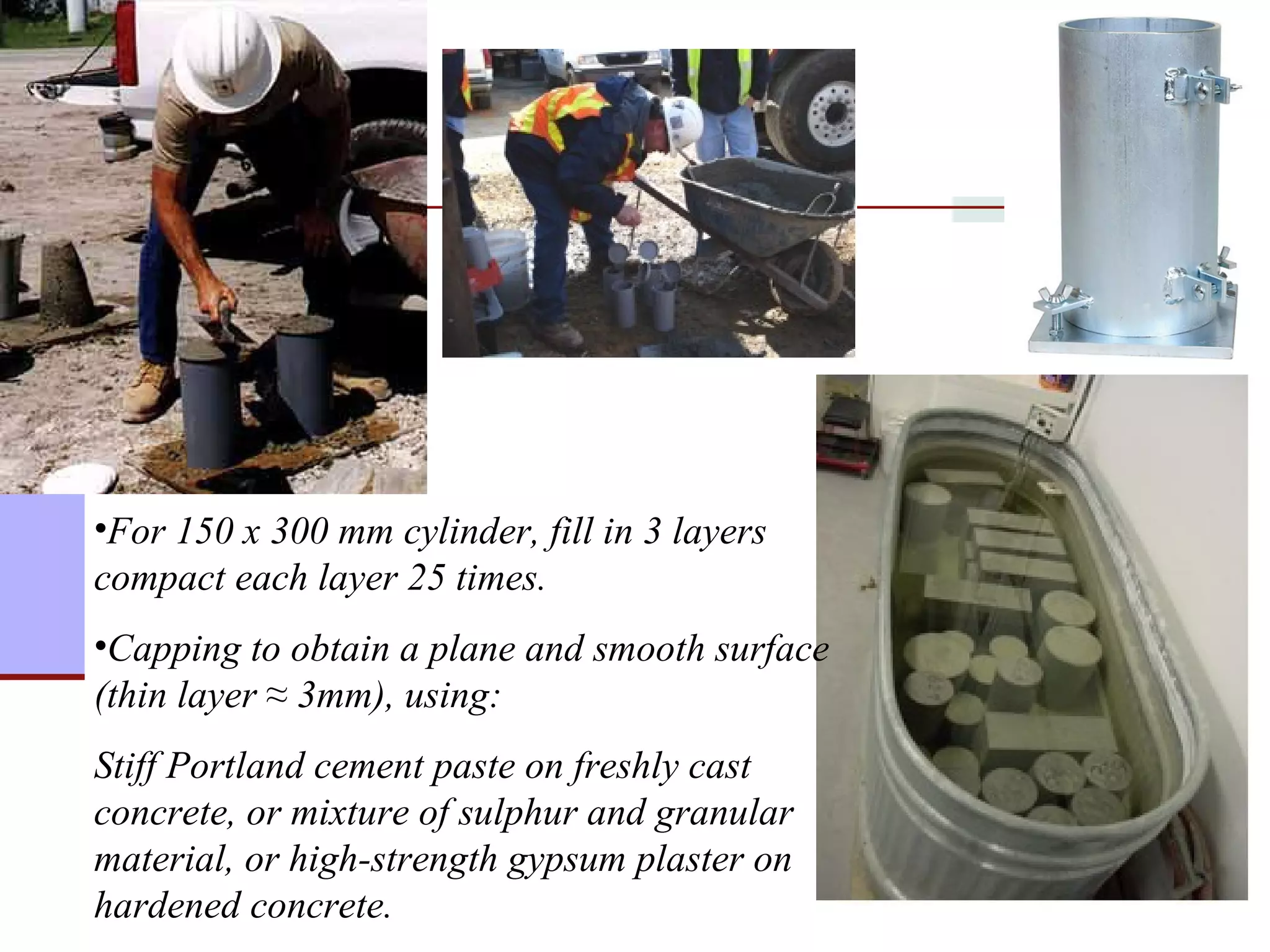

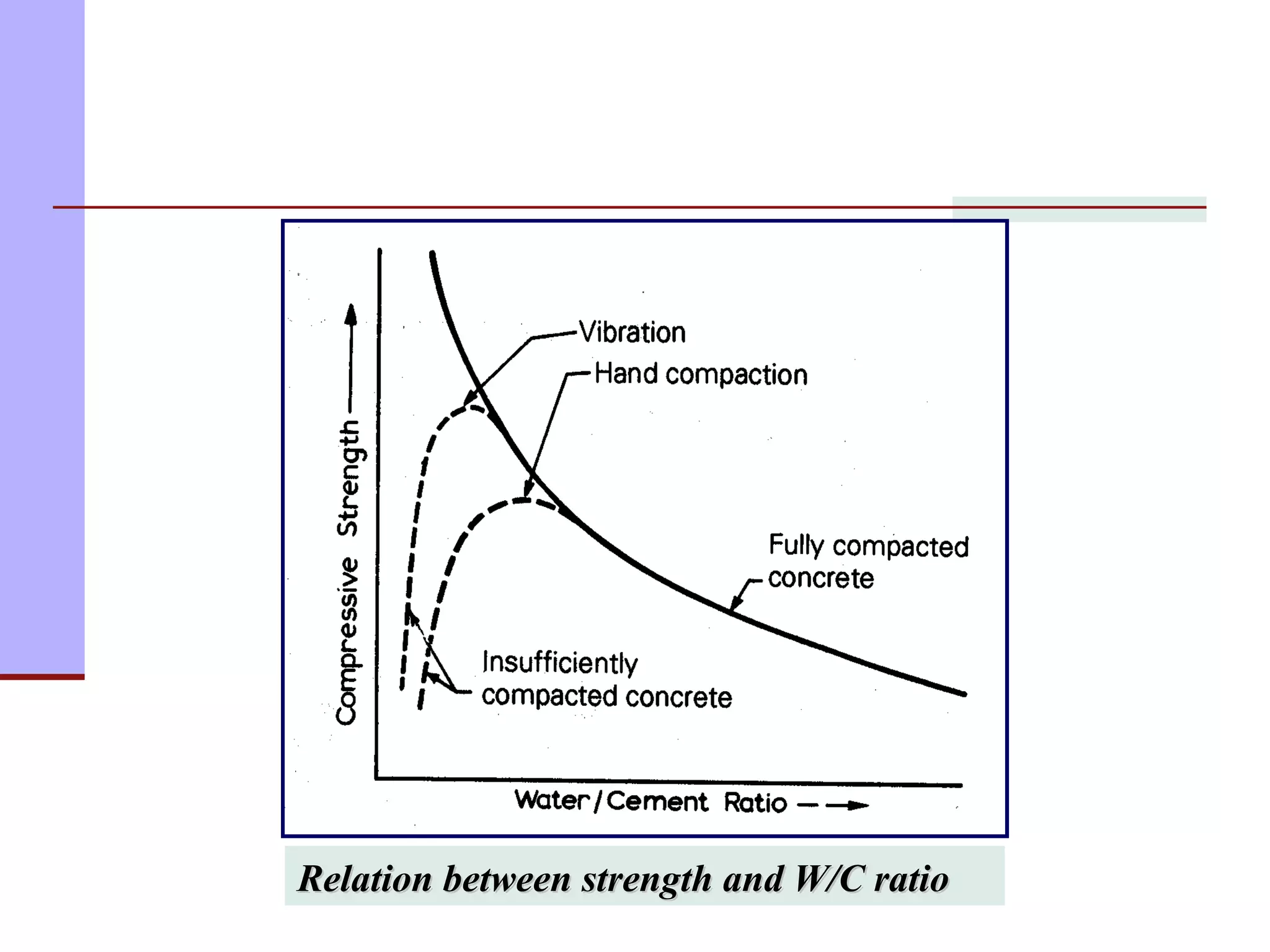

1. Concrete strength is tested using cubes or cylinders according to standardized methods like ASTM C470. Compressive strength increases with lower water-cement ratio and full compaction.

2. Factors that affect concrete strength include water-cement ratio, degree of compaction, curing time, cement composition and fineness, aggregate properties like size and texture.

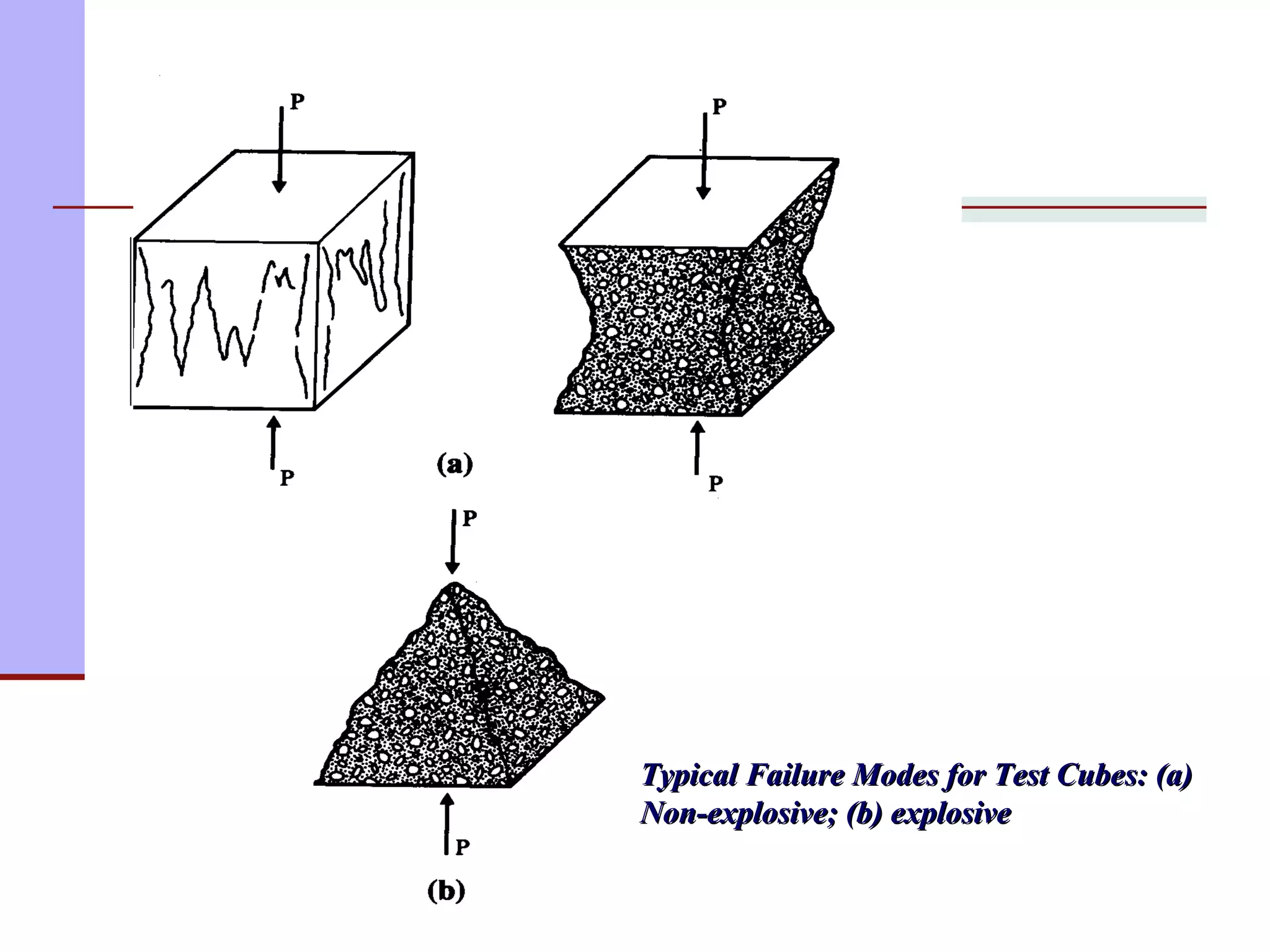

3. Common failure modes for cubes are non-explosive or explosive, while cylinders typically fail via splitting, shearing, or a combination. Tensile strength is about 10% of compressive strength.