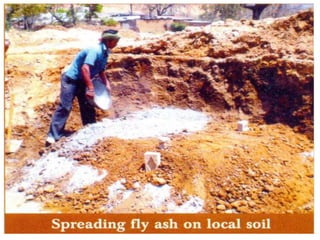

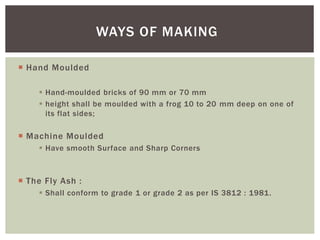

The document discusses the concept and manufacturing processes of clay fly ash bricks, including the benefits of using fly ash from thermal power plants to alleviate topsoil depletion. It highlights the current high usage of coal for power generation in India and outlines the specifications and standards for brick quality and dimensions. Key advantages of fly ash bricks include reduced waste, lower costs, and improved efficiency in brick production.