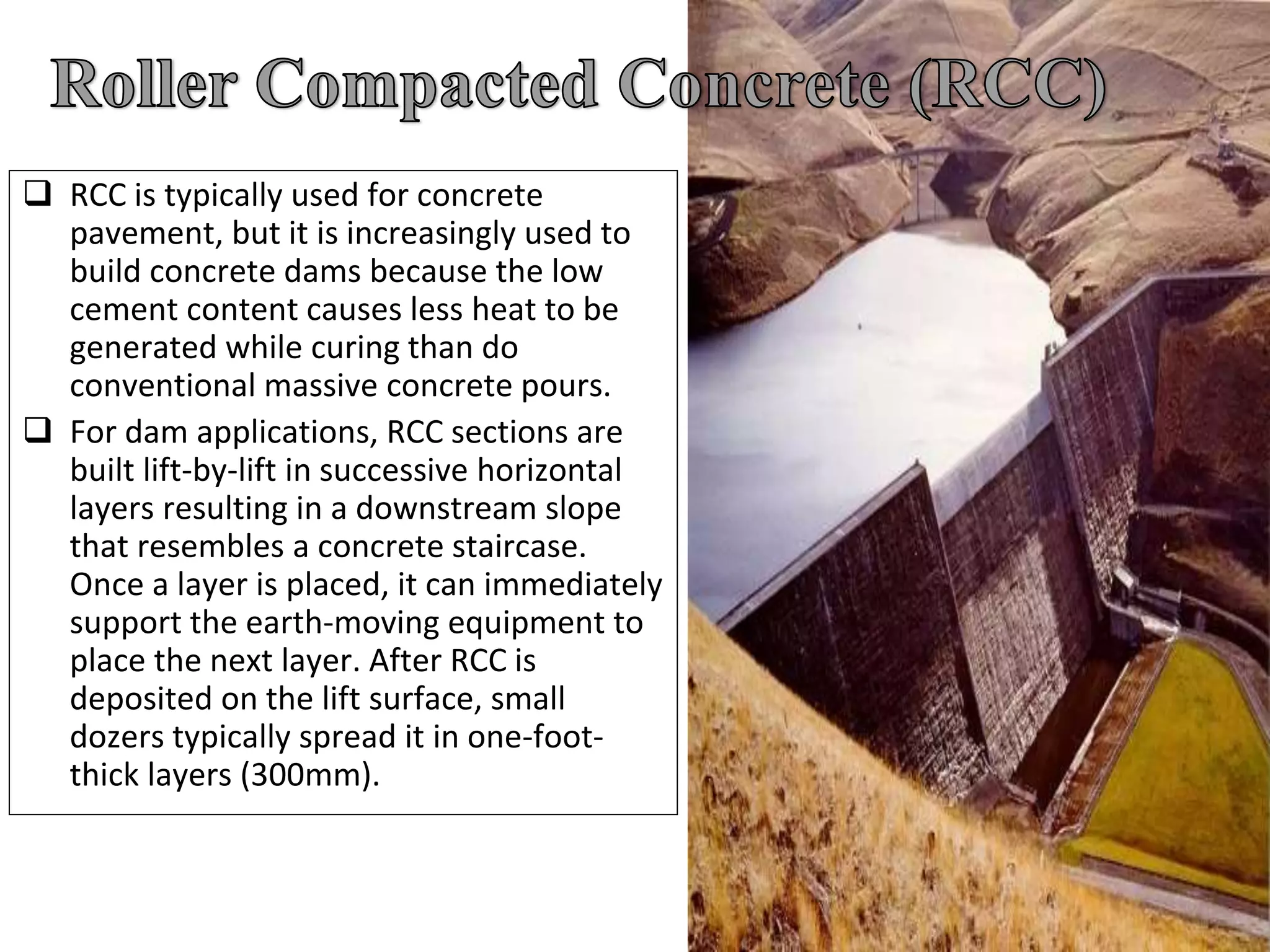

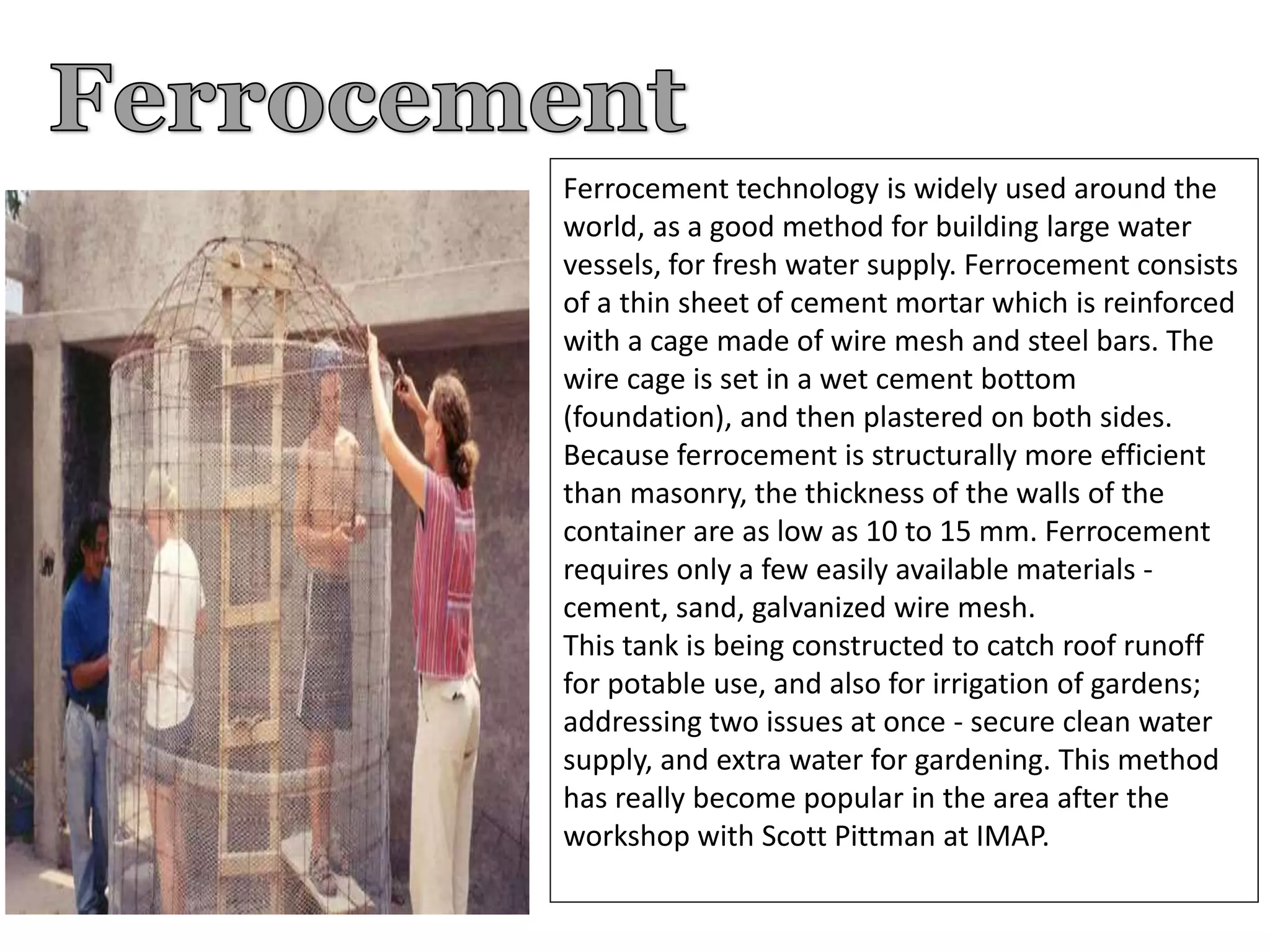

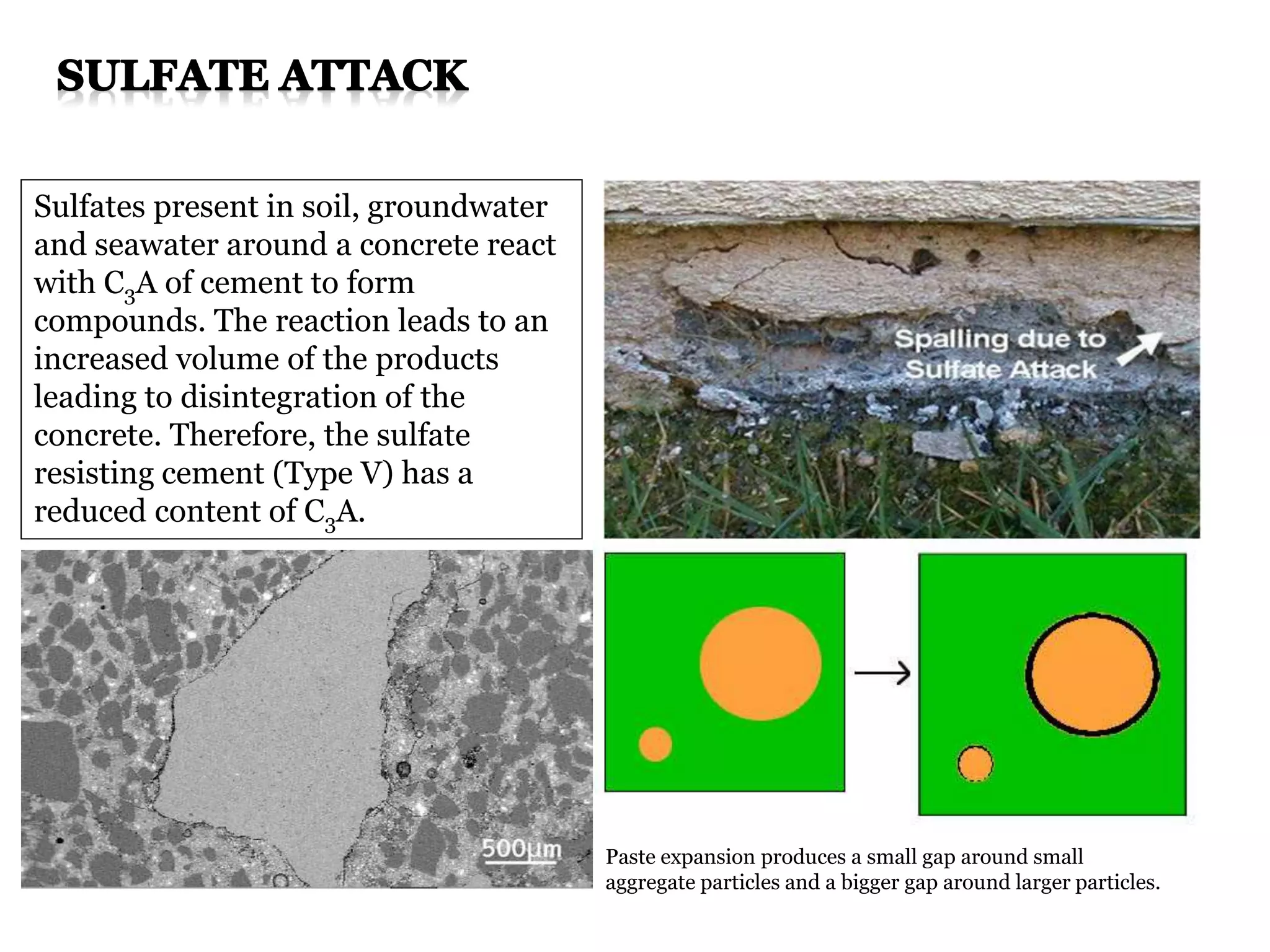

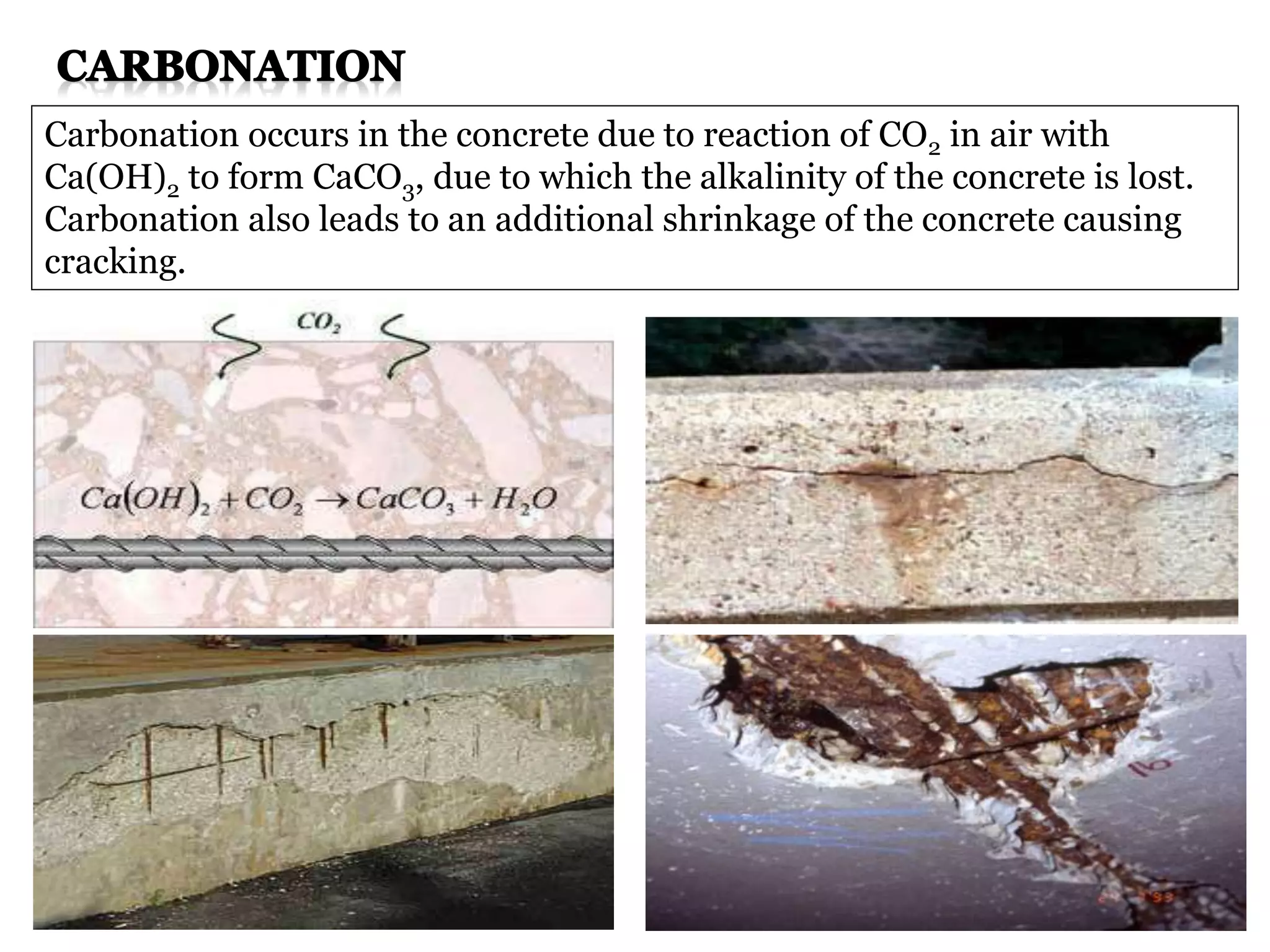

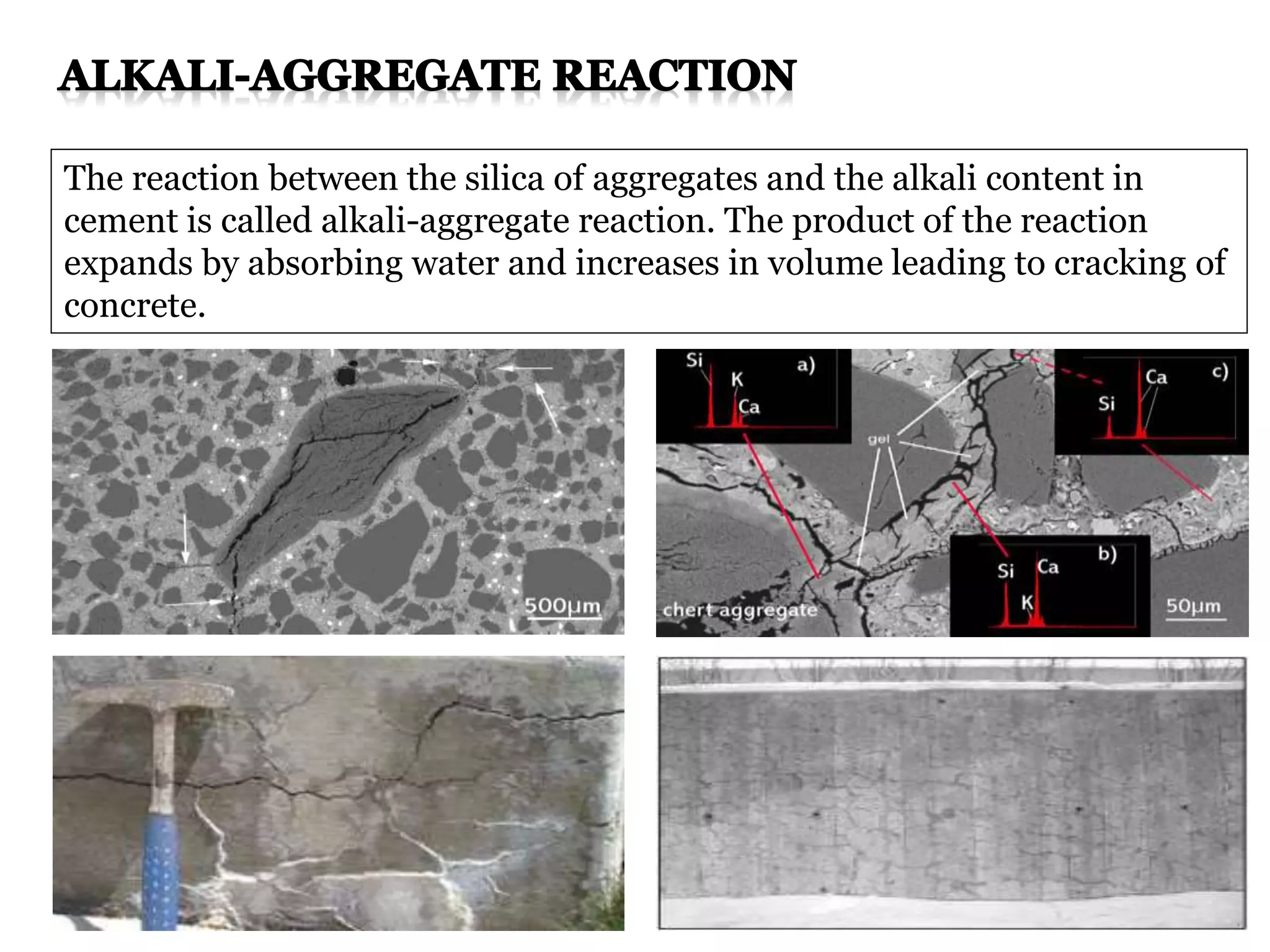

This document provides information on different types of concrete, including their compositions and uses. It discusses aggregates, which make up 60-75% of concrete's total volume. It also summarizes different concrete classifications based on strength (ordinary, high-strength, polymer), design (plain cement, reinforced cement), and compaction method (roller-compacted). Additional topics covered include fiber-reinforced concrete, ferrocement, and durability issues like chloride, sulfate, carbonation, alkali-aggregate, and acid attacks.