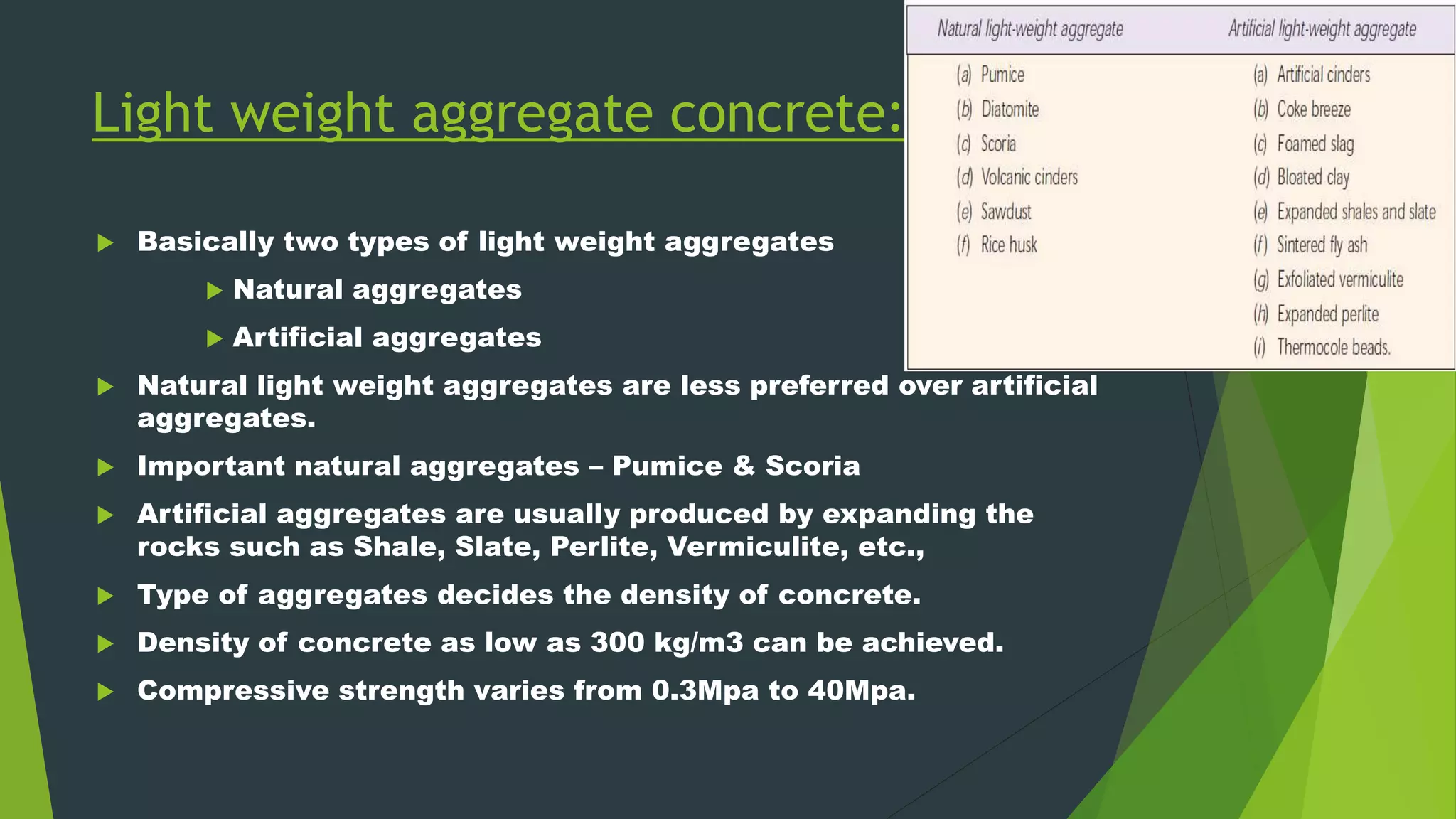

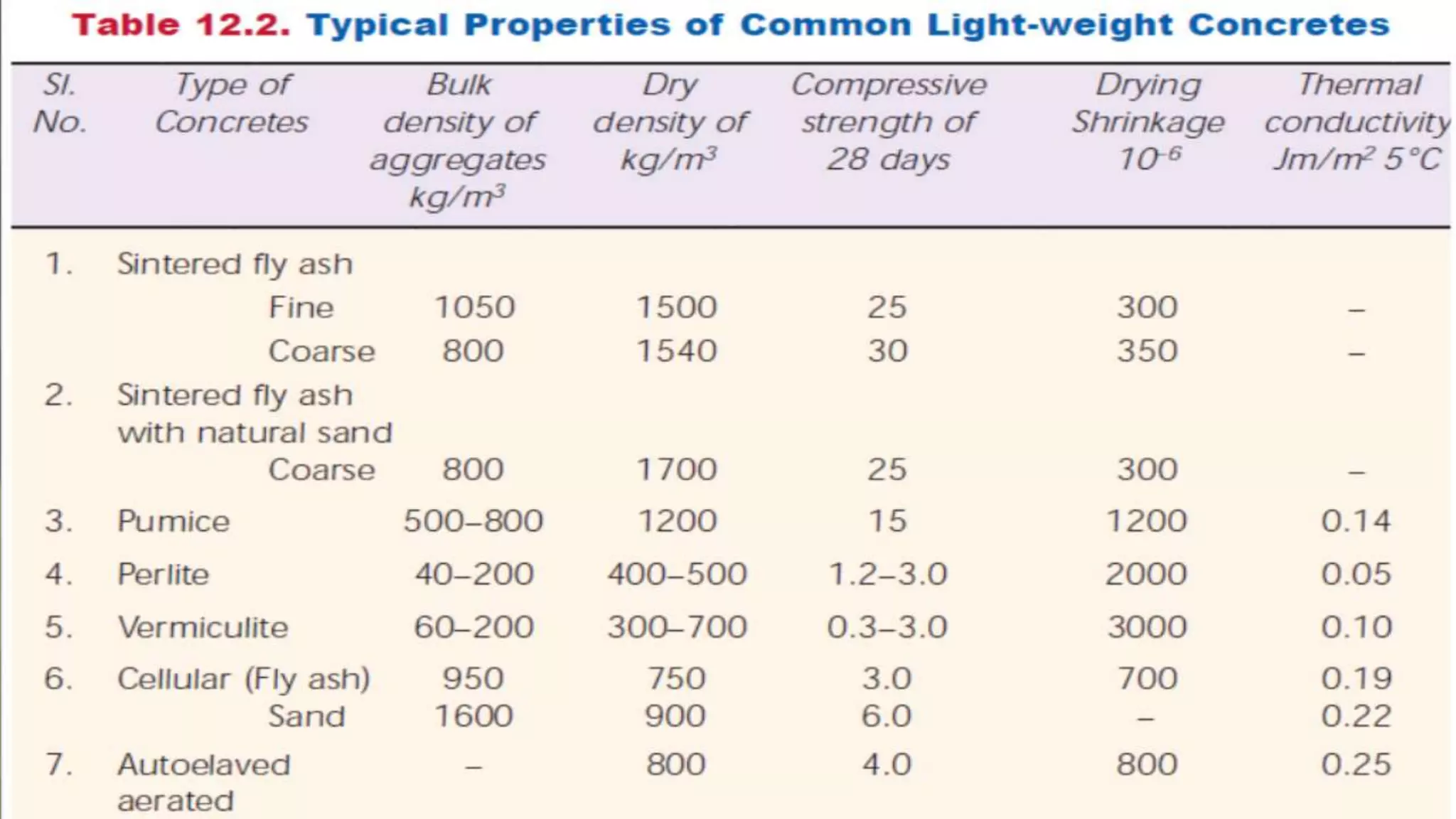

Lightweight concrete has a density of 300-1850 kg/m3 compared to 2200-2600 kg/m3 for normal concrete. It is made with lightweight aggregates which can be natural like pumice or artificial like expanded shale. Lightweight concrete has applications in structural and non-load bearing construction due to its strength while also providing benefits like reduced weight, improved insulation, and easier construction. Proper mix design is important due to the variable water absorption of aggregates.