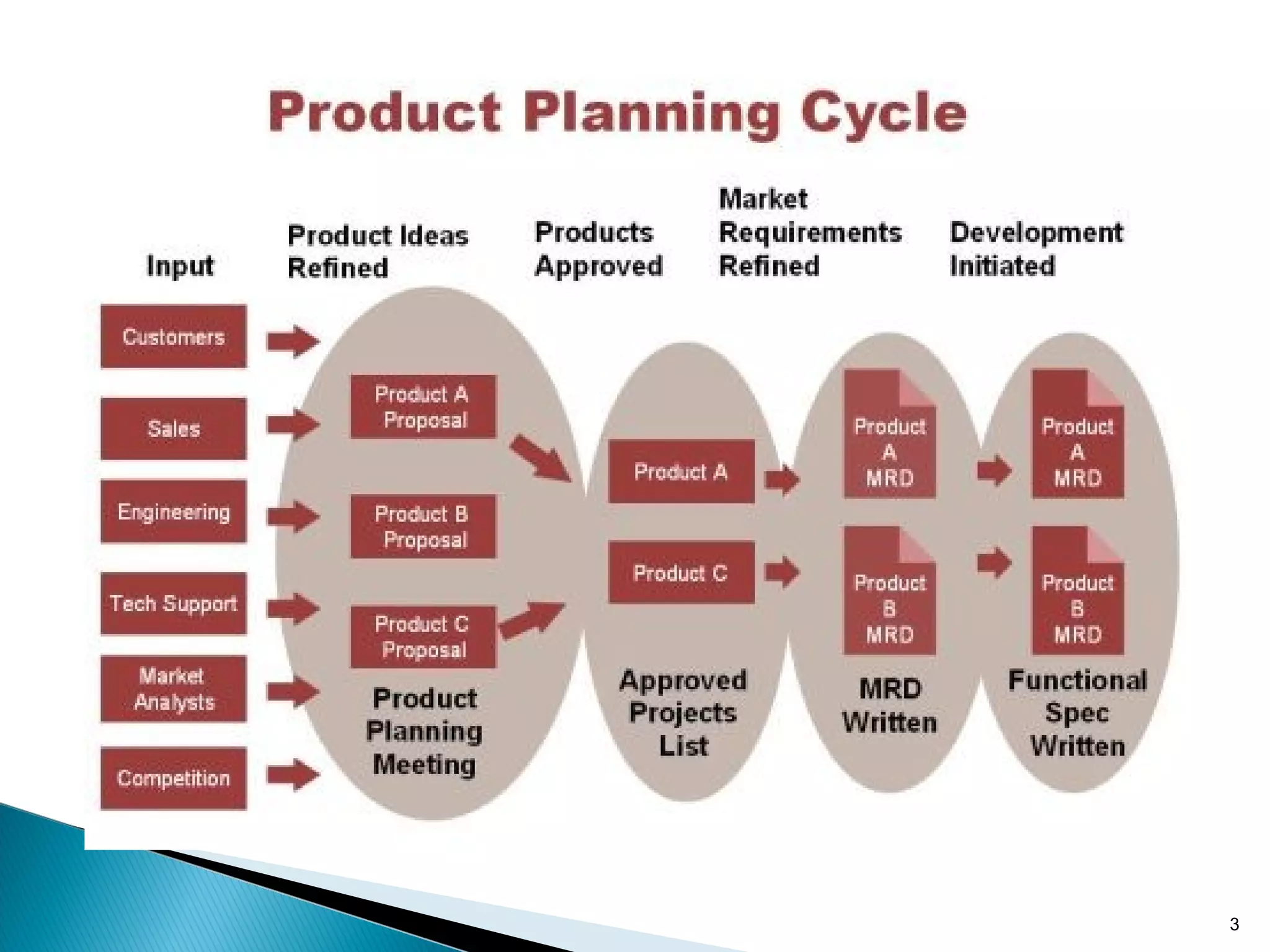

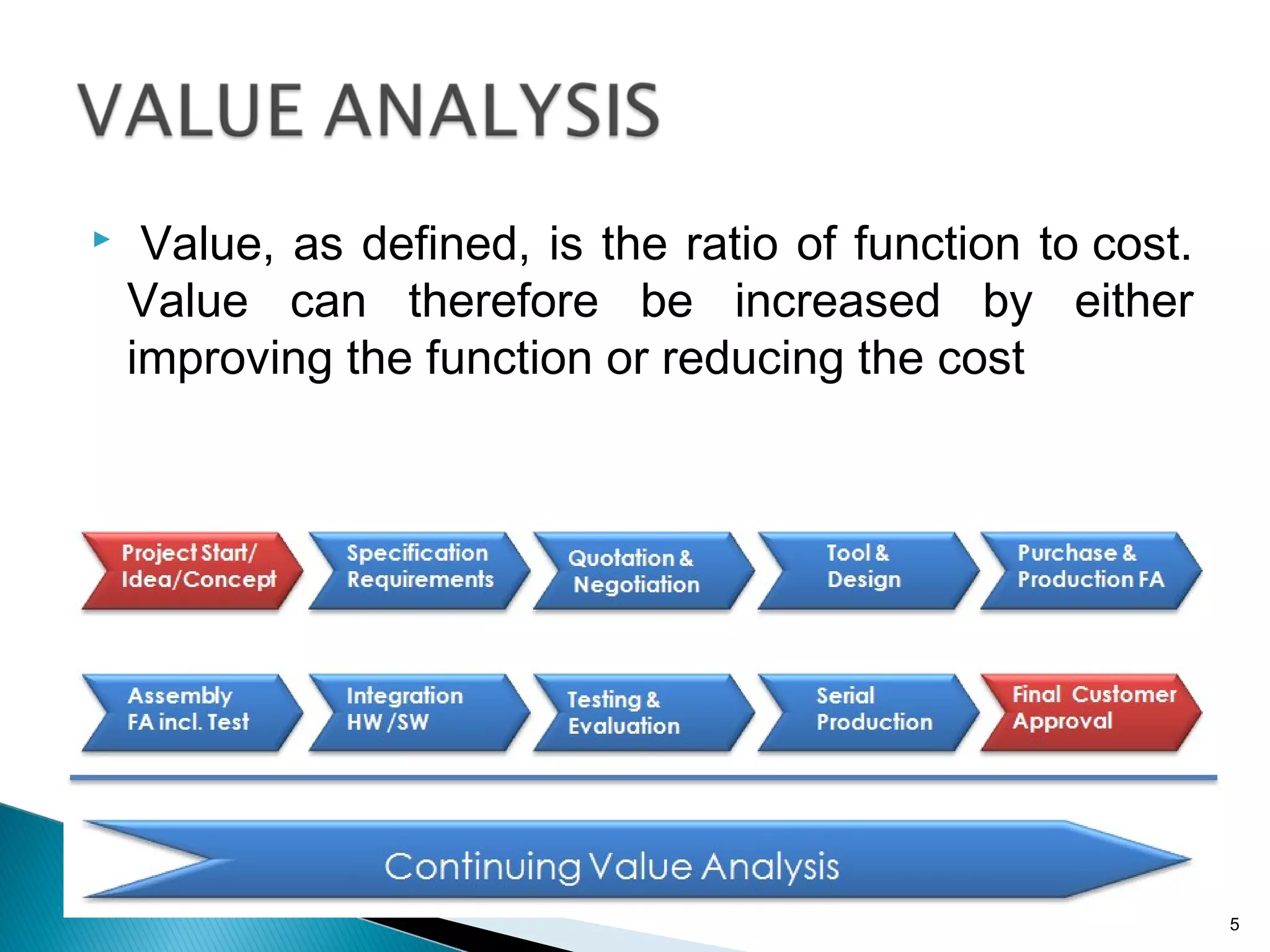

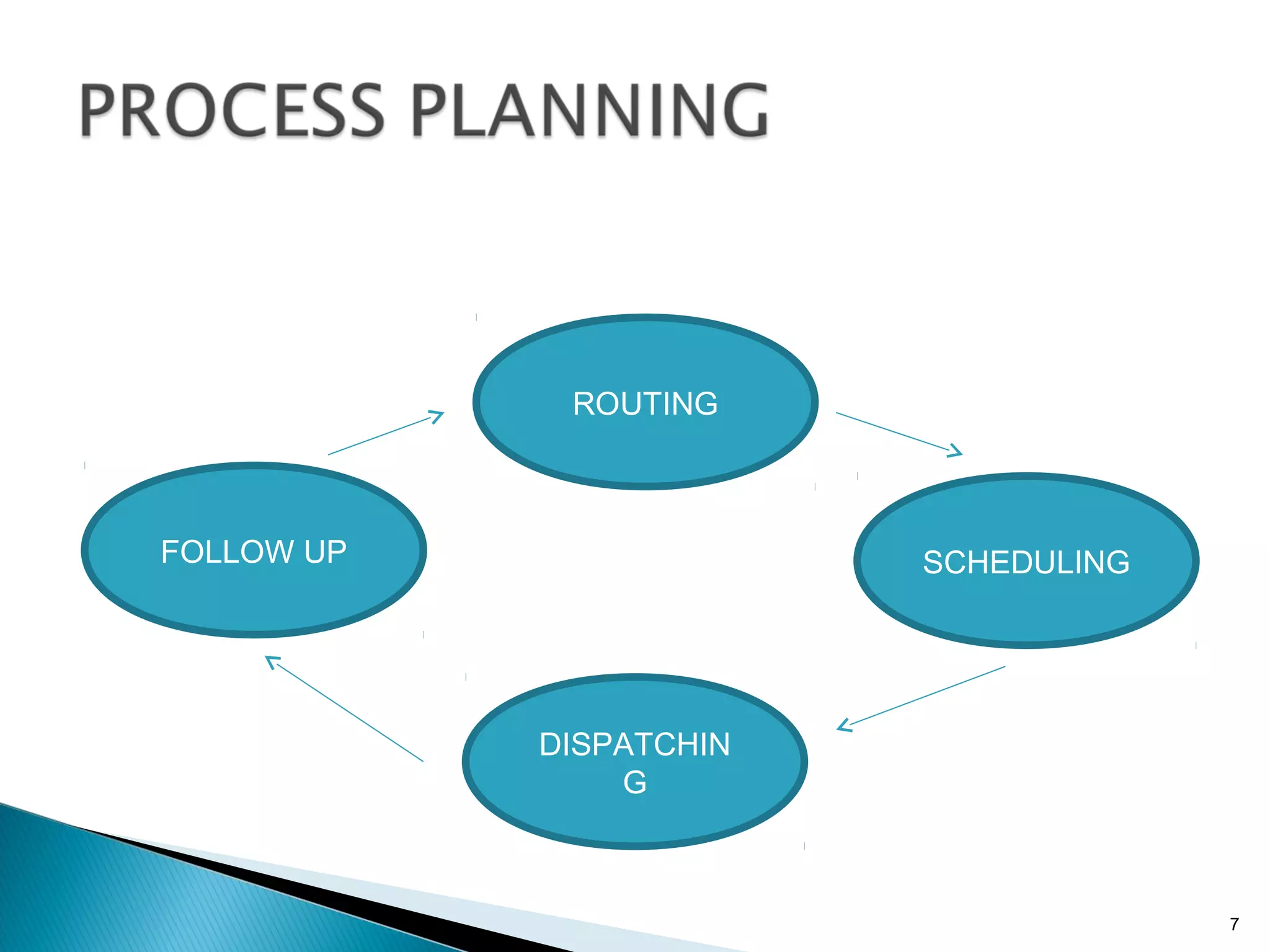

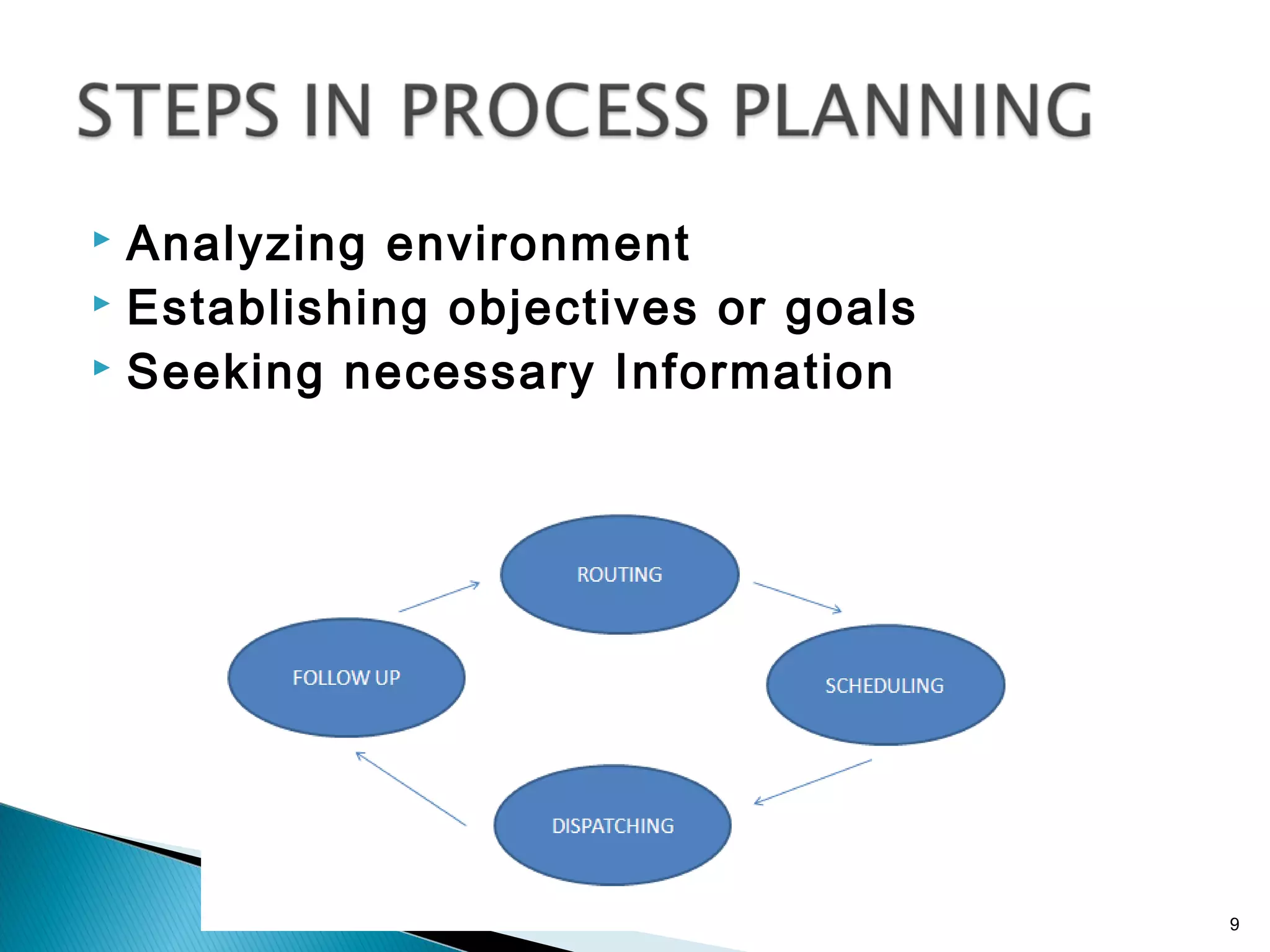

This document discusses product planning, value, customer satisfaction, logistics processes, and economic batch quantity modeling. It notes that product planning identifies market requirements to define a product's features and serves as the basis for pricing, distribution, and promotion decisions. It also defines value as the ratio of function to cost, which can be increased by improving function or reducing costs. Additionally, it lists factors that can lead to customer dissatisfaction and outlines key considerations for logistics like products, processes, capacity, orders, and resources. Finally, it provides background on economic batch quantity modeling including assumptions, variables, and the formula for calculating optimal batch size.