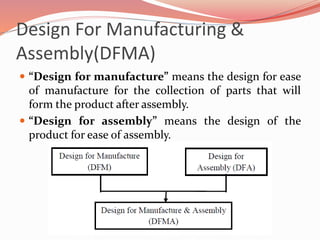

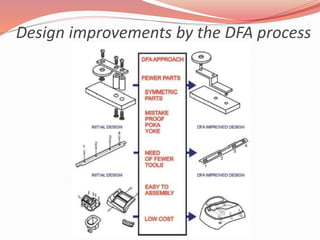

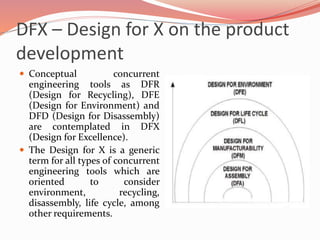

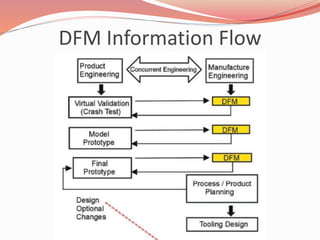

Concurrent engineering is a simultaneous approach to product design and development that accelerates time-to-market while reducing costs and enhancing quality through collaboration across multidisciplinary teams. It includes methodologies such as design for manufacturing and assembly, which focus on improving manufacturability and assembly efficiency through optimized designs. The application of these principles in industries, particularly automotive, yields notable benefits including reduced production costs, improved logistics, and increased productivity.