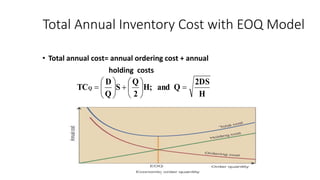

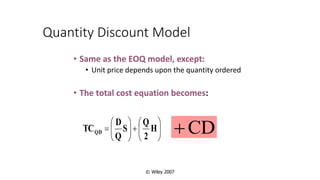

The document discusses inventory models and concepts. It defines inventory as resources set aside for future use. It discusses the importance of inventory control for organizational success and different types of inventories. It describes basic inventory decision problems like how much and when to replenish inventory. It introduces the Economic Order Quantity (EOQ) model and Economic Production Quantity (EPQ) model for determining optimal order quantities and minimizing total inventory costs.