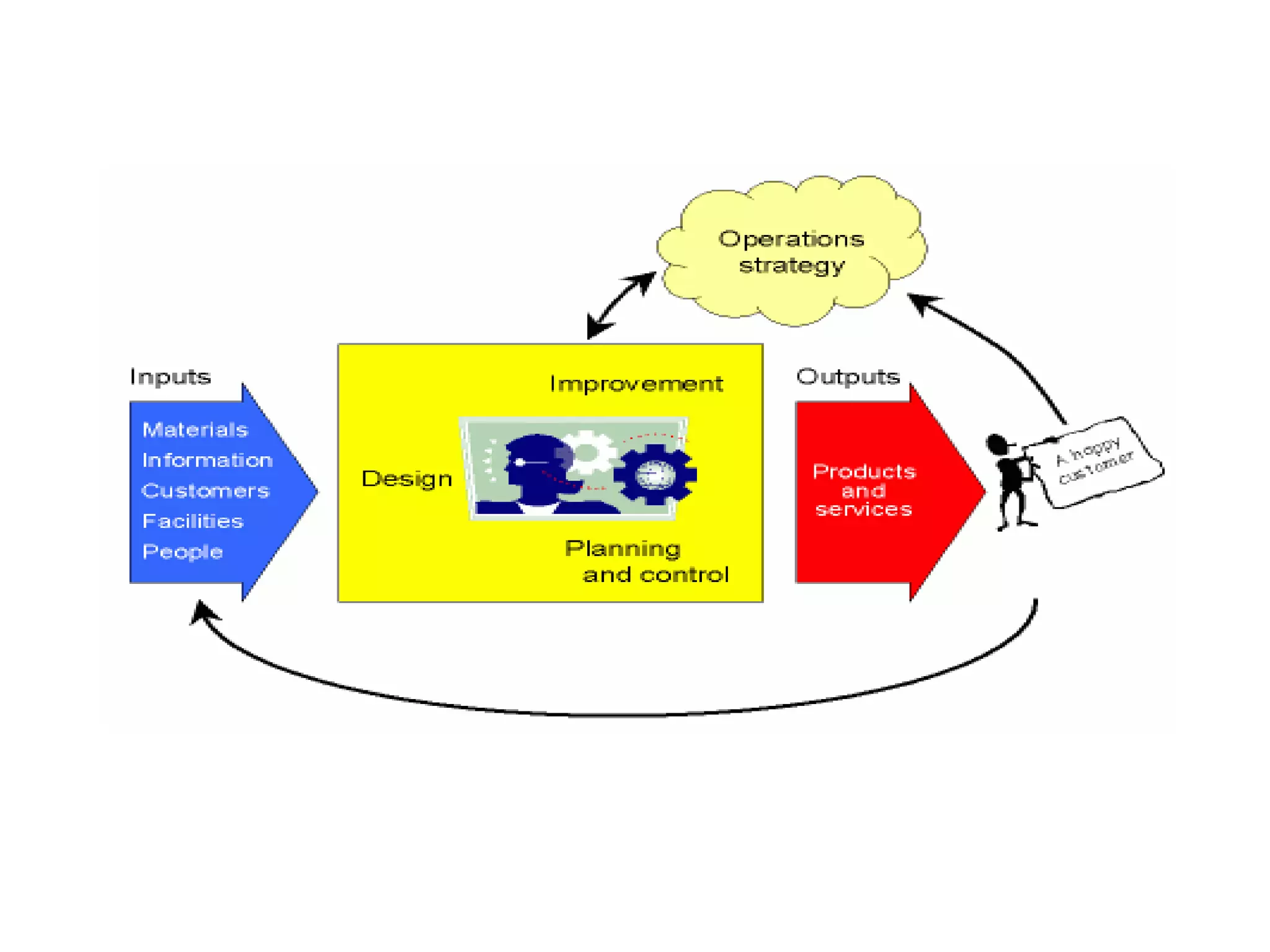

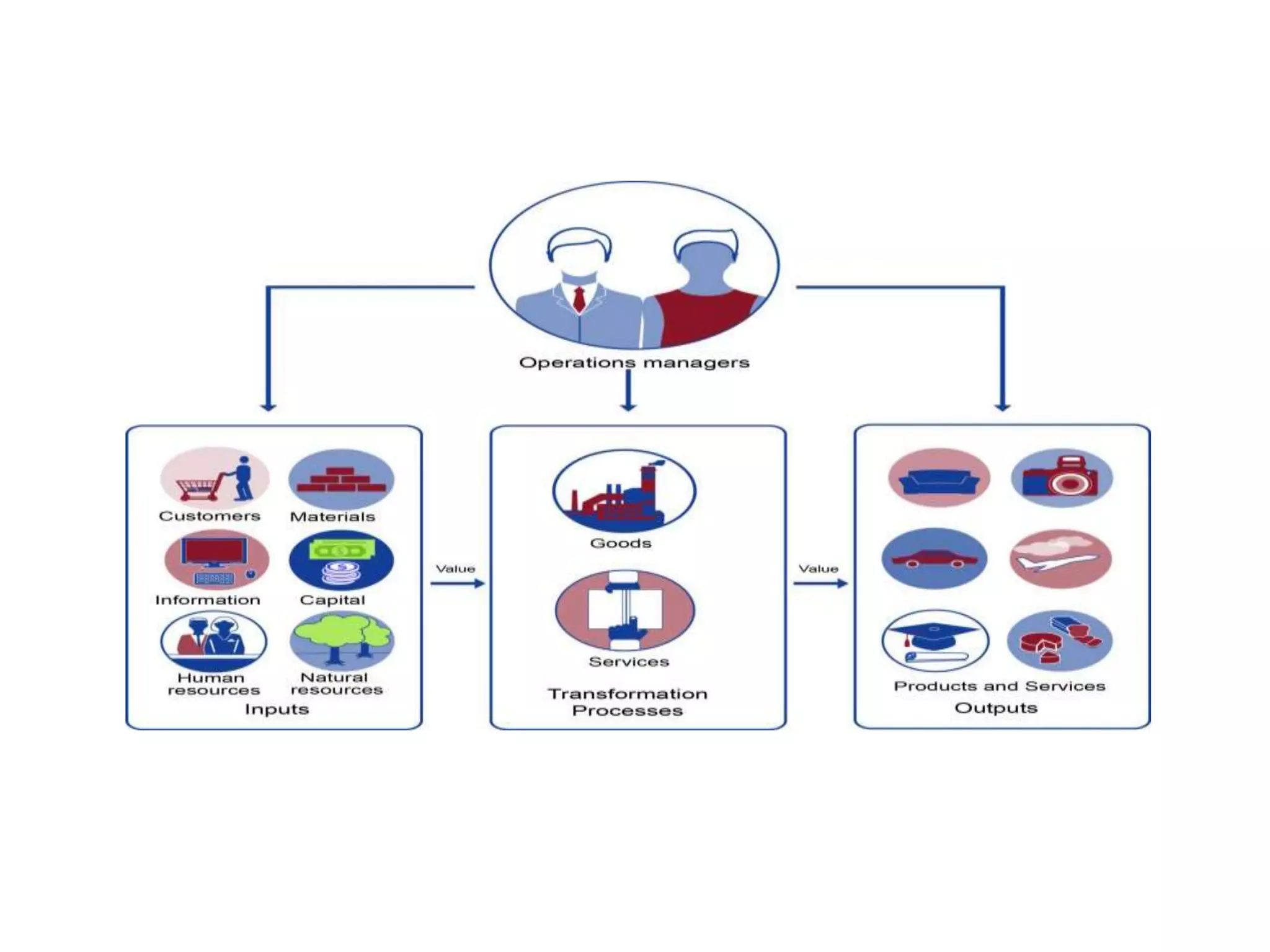

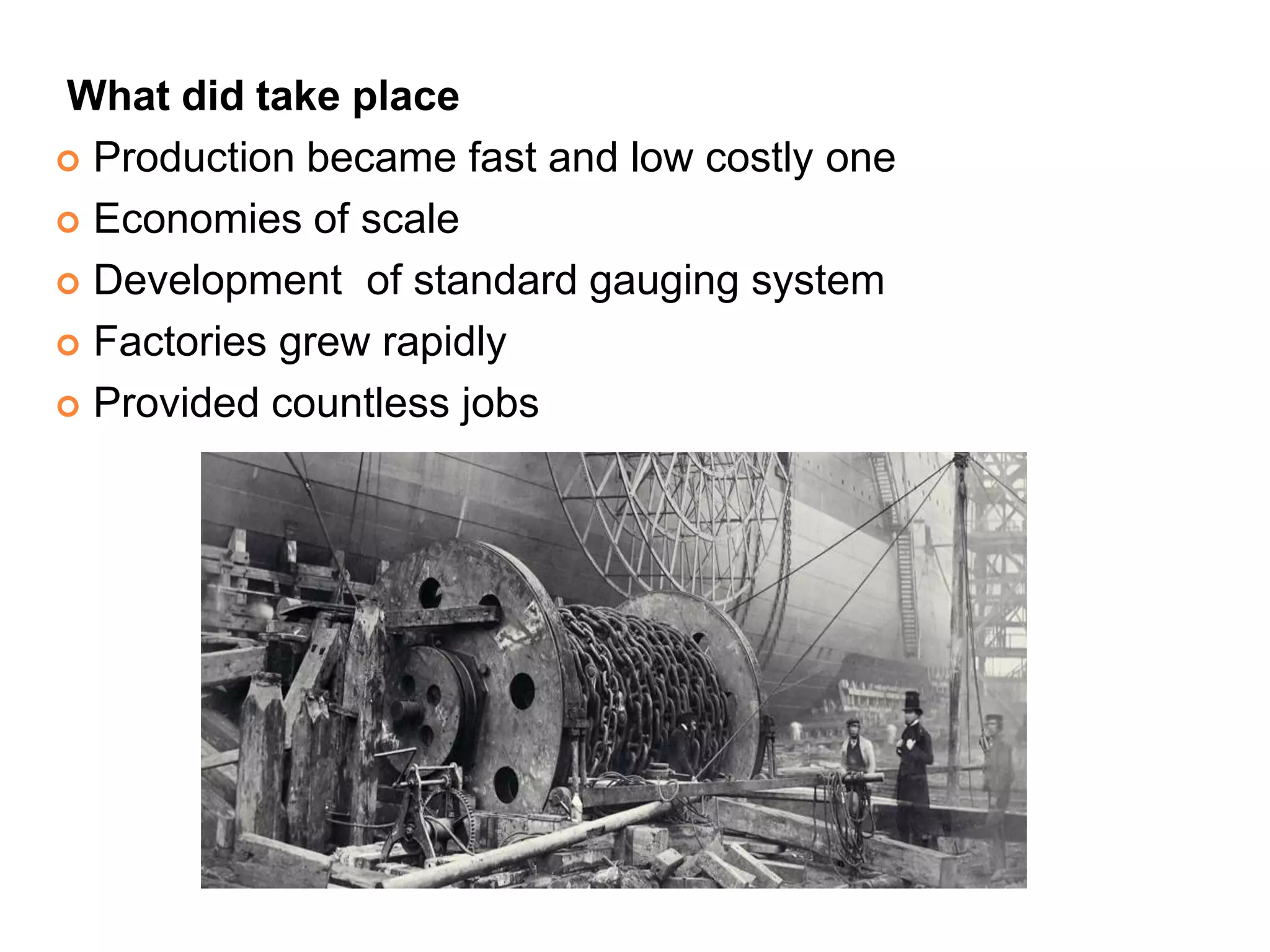

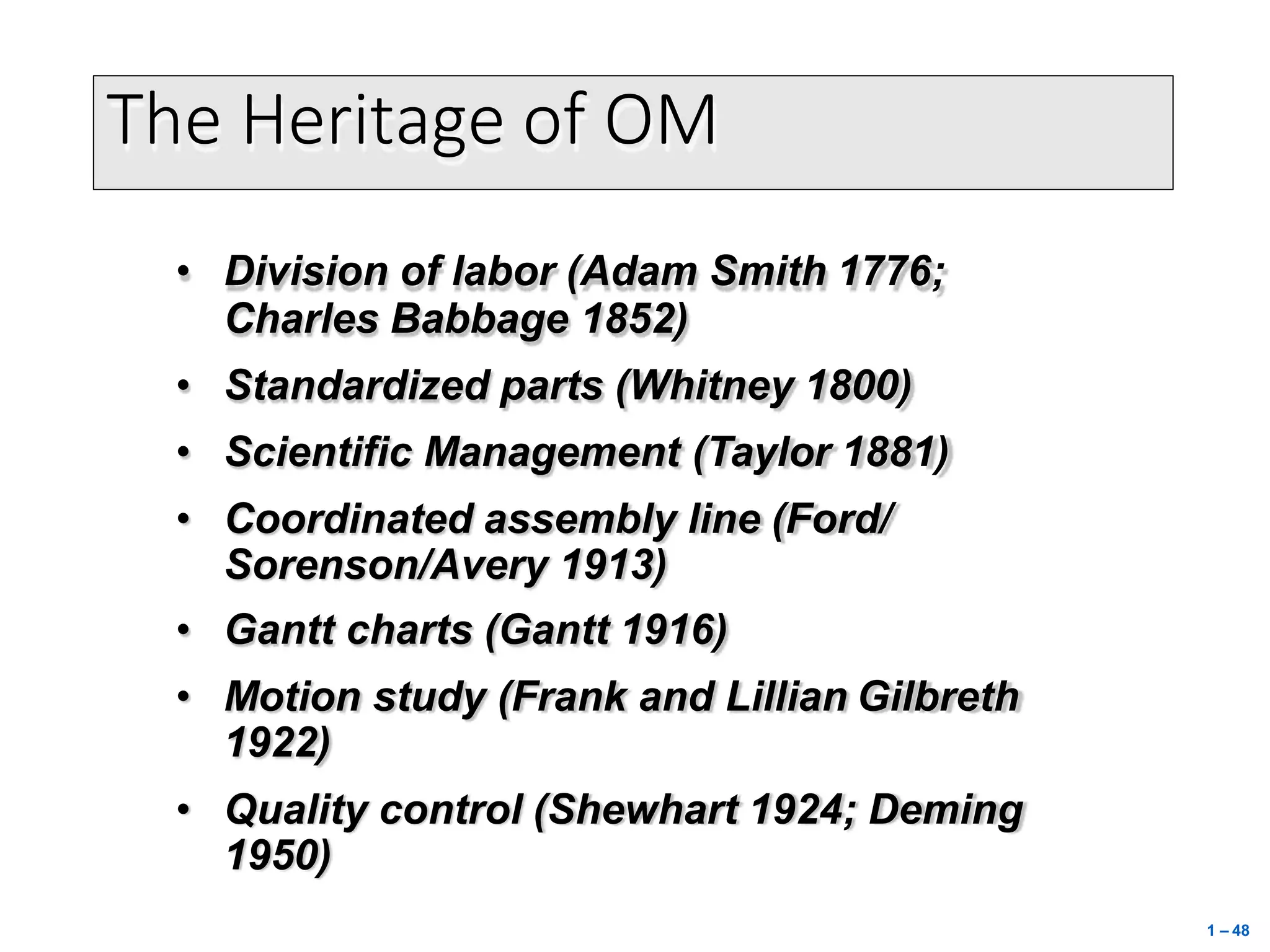

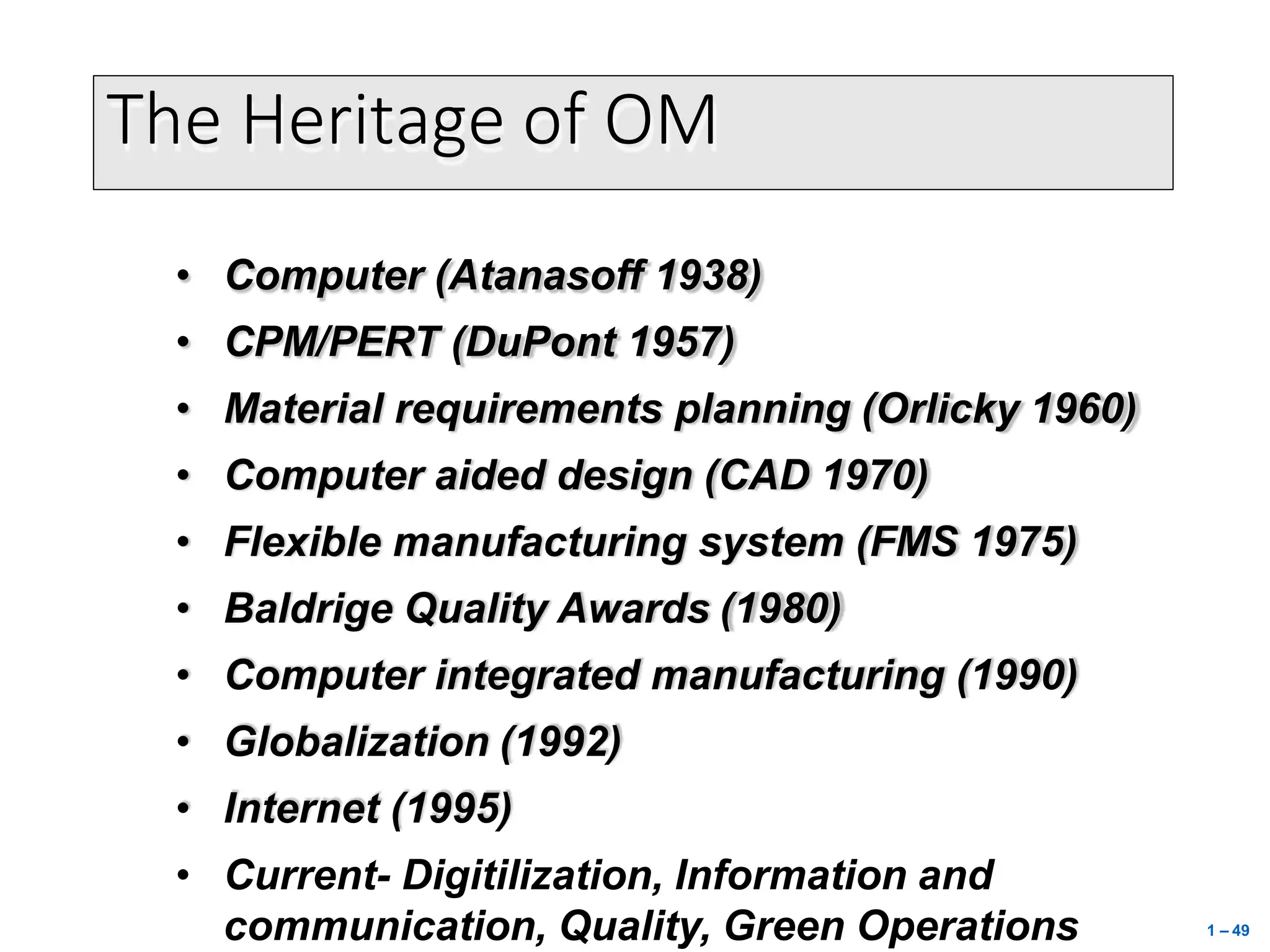

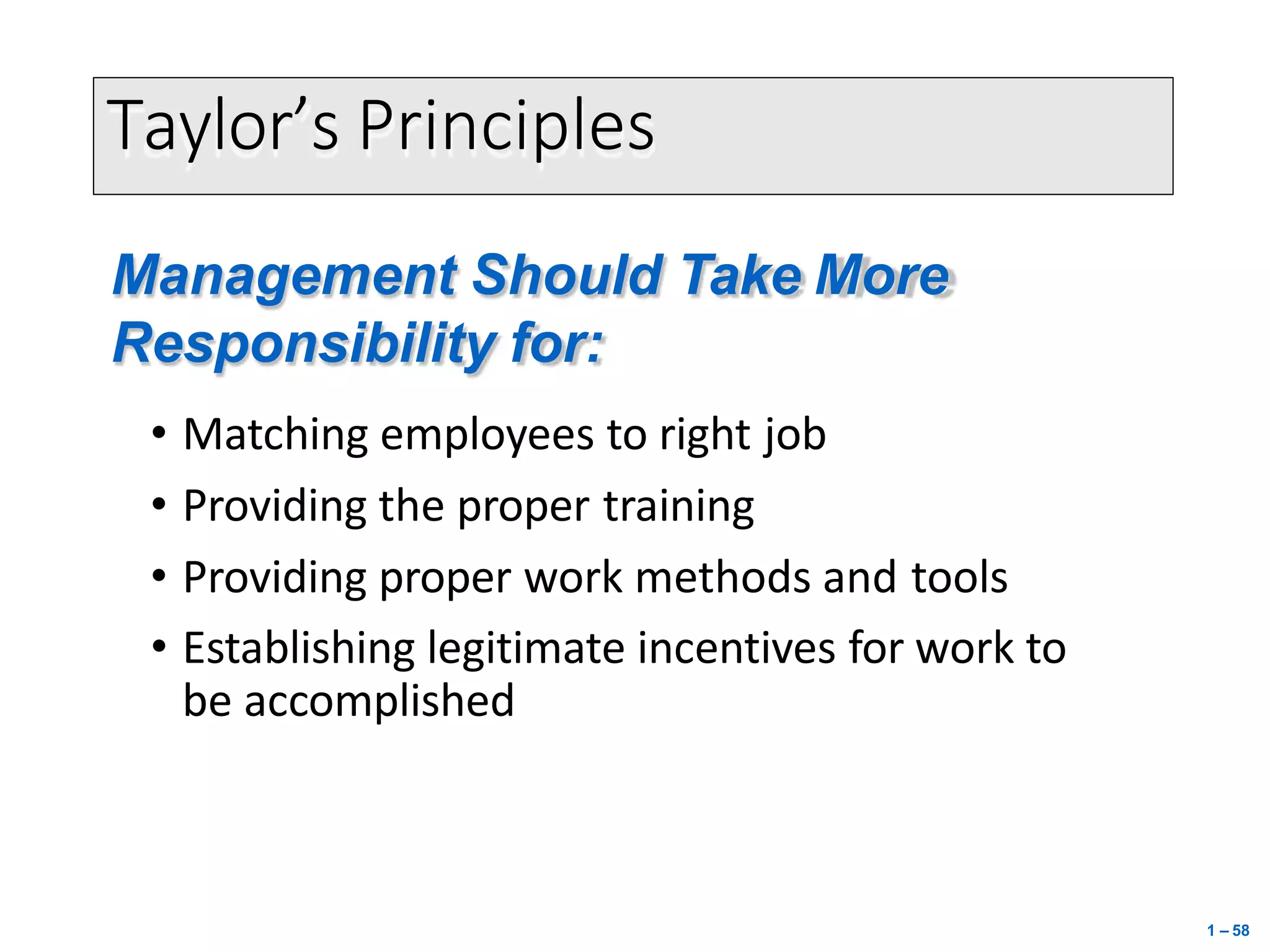

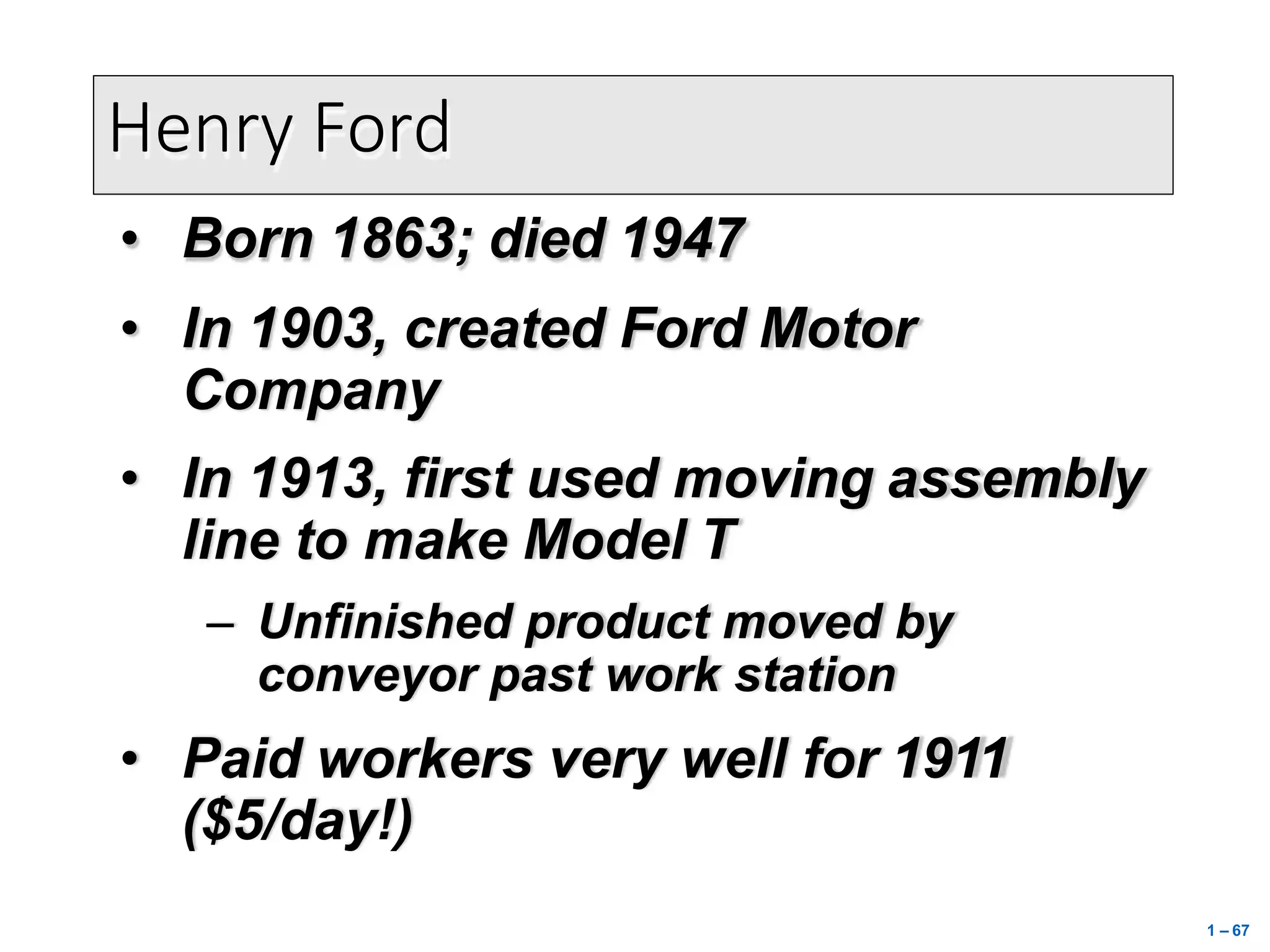

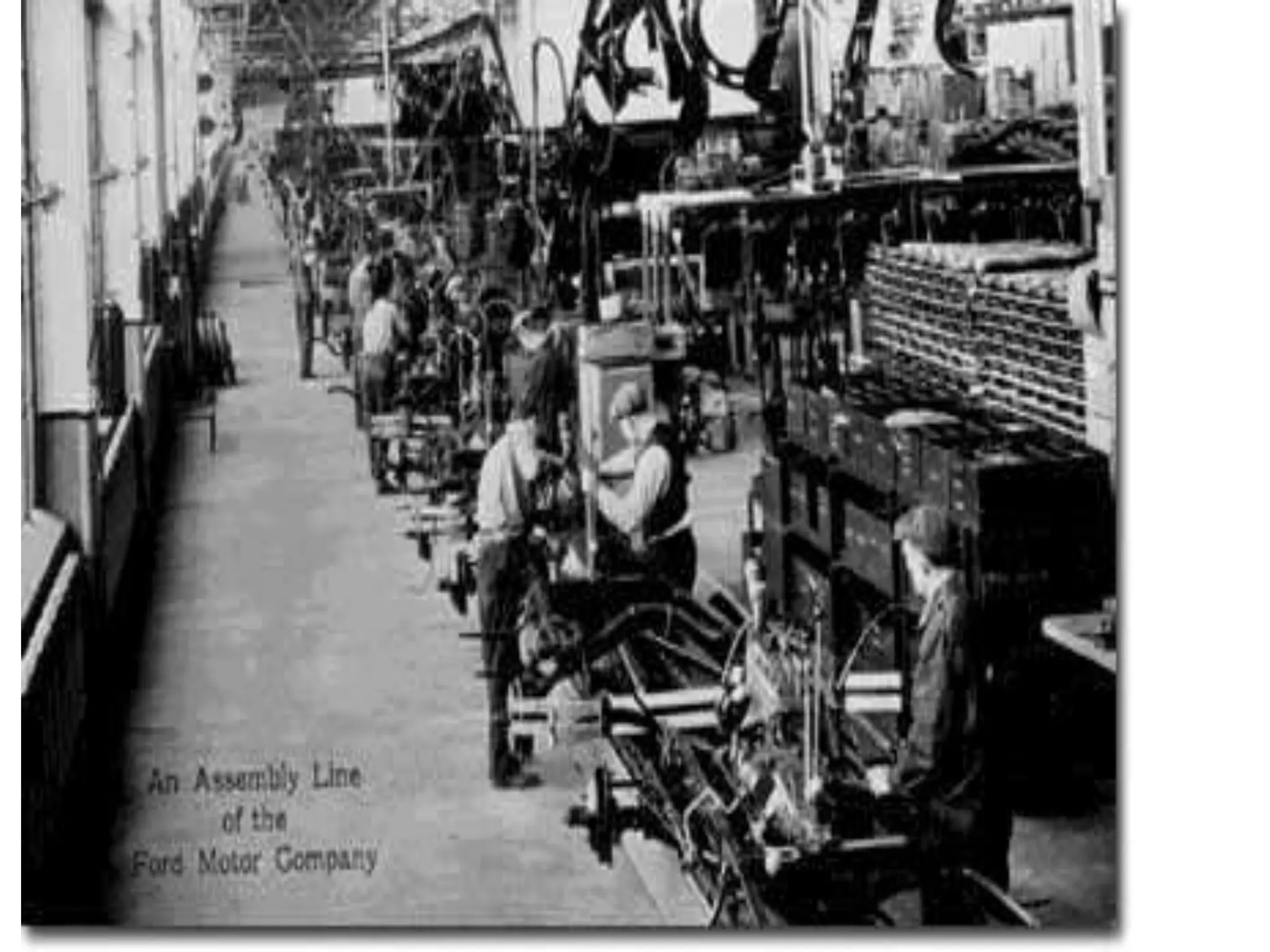

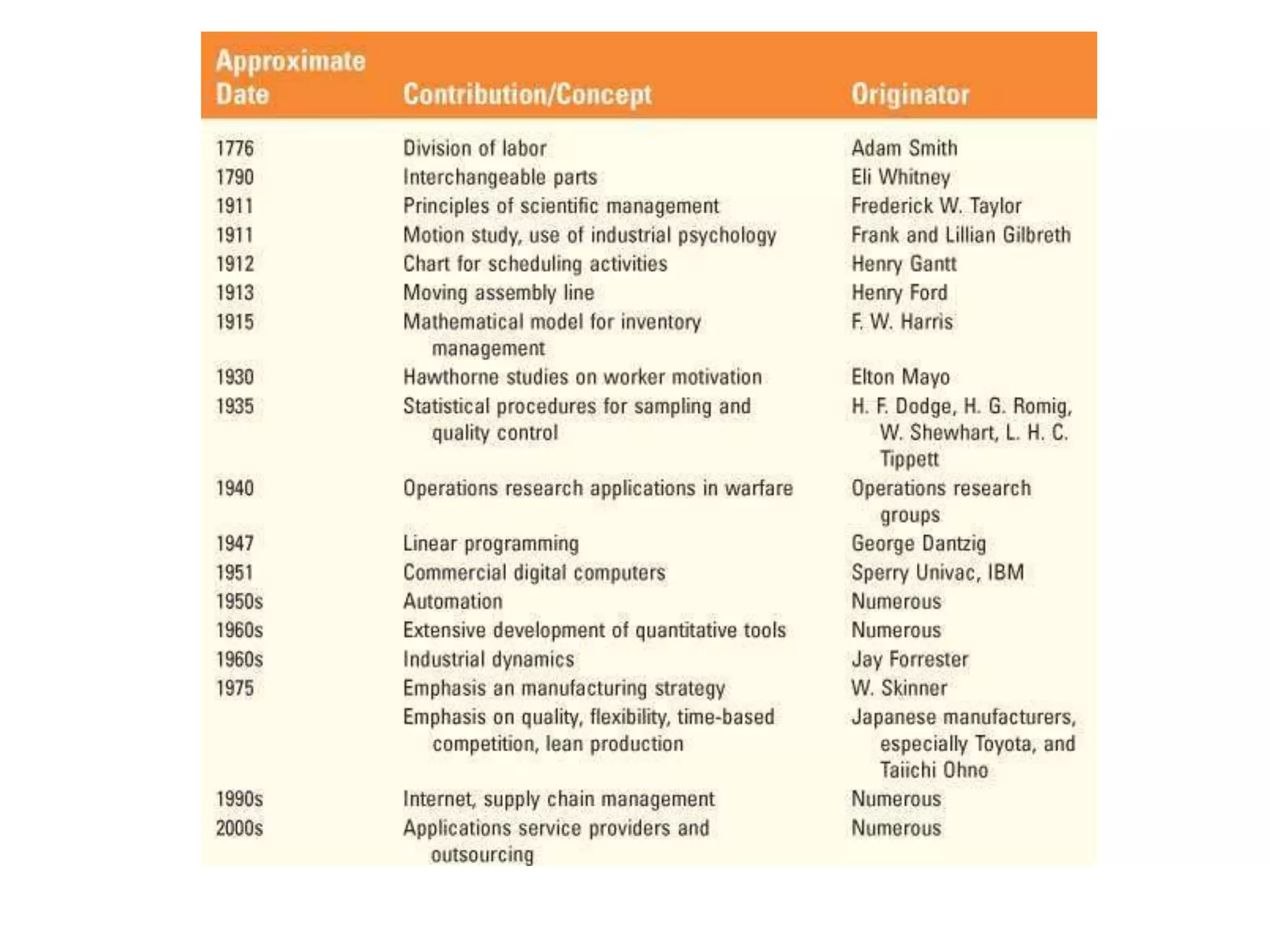

Frederick Taylor was a pioneer in scientific management who applied engineering principles to operations management. The document discusses Taylor's contributions and provides context on the evolution of operations management from early thinkers like Adam Smith to modern concepts. It also summarizes key events like Eli Whitney's invention of interchangeable parts and the assembly line innovations of Henry Ford. Overall the document provides a high-level history of the field of operations management from its origins to the present day.