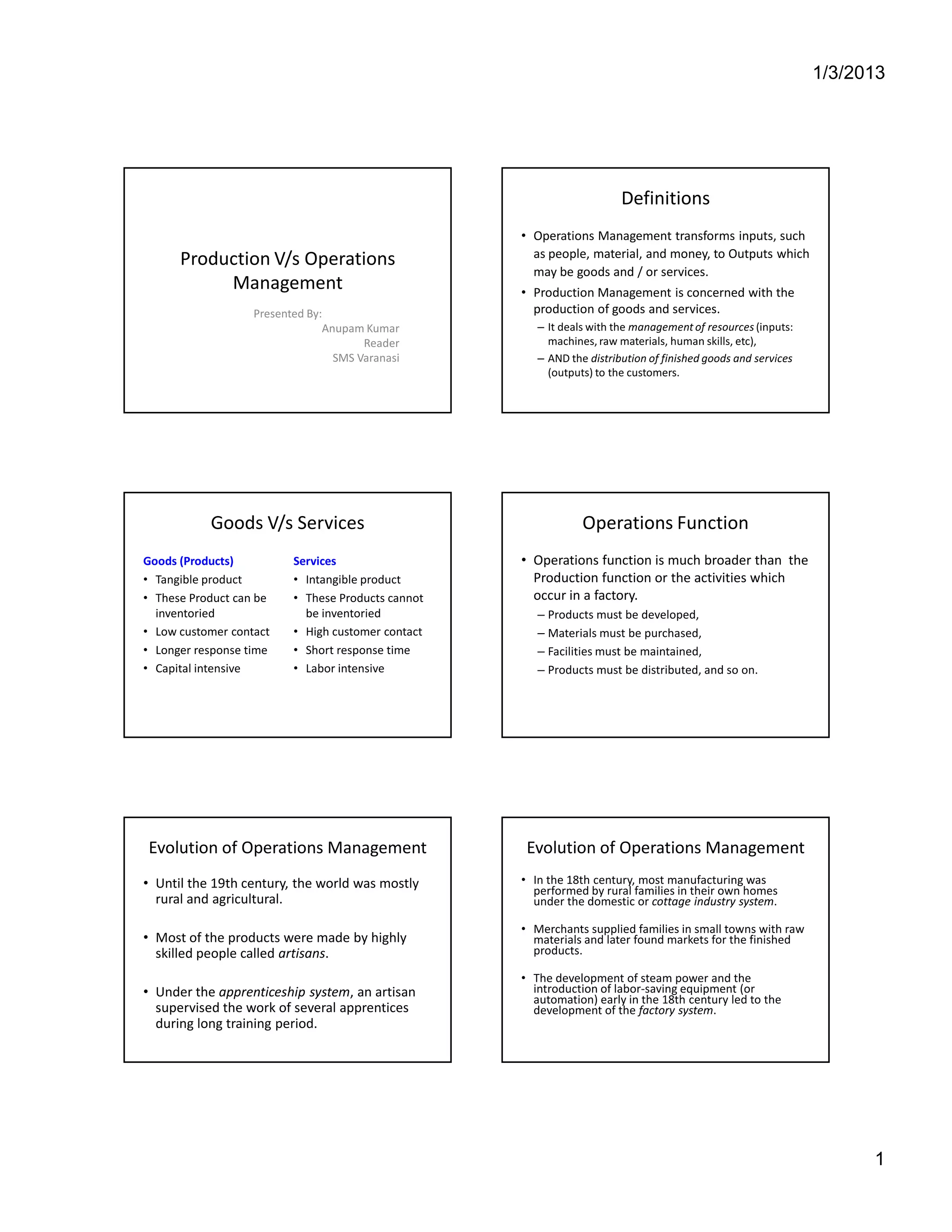

Operations management transforms inputs like people, materials, and money into outputs like goods and services. Production management specifically deals with producing goods and services by managing resources and distributing finished products. Over time, operations management has evolved from individual artisans to large factories using specialized labor and automation. Frederick Taylor introduced scientific management approaches to minimize costs. Later studies showed the importance of psychological factors in worker motivation. Today, operations management utilizes quantitative models, statistics, information technology, and computer systems to efficiently manage complex operations.