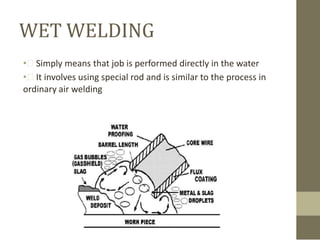

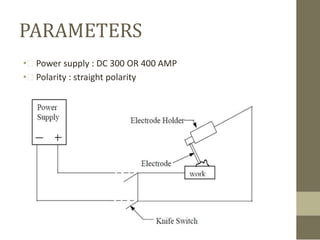

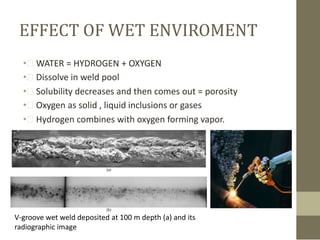

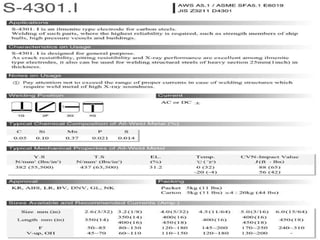

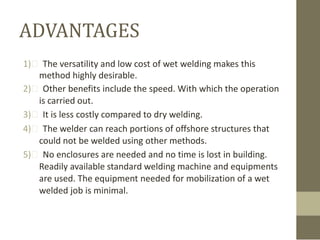

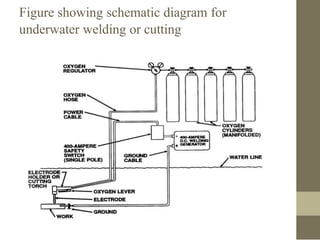

The document discusses underwater welding, detailing its history, methods (wet and dry), advantages, and challenges encountered during operations. It highlights the significance of underwater welding in repairing offshore structures and the need for advanced techniques to improve weld quality, particularly in deep water. Recent developments include automation in welding processes and alternative techniques such as friction and explosive welding.