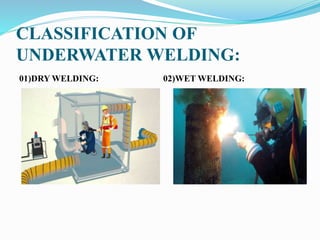

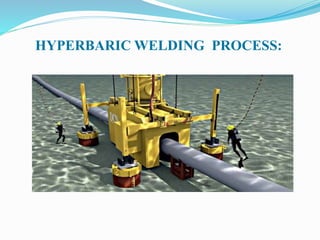

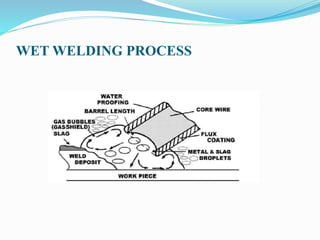

This document provides an overview of underwater welding, including its classification into dry and wet welding. Dry welding uses a sealed chamber filled with gas, while wet welding is done directly in water using special electrodes. The document discusses the applications, environmental factors, inspection methods, risks, and potential areas of future development for underwater welding. These include automation, new techniques like laser welding, and using robots to reduce risks to human divers.