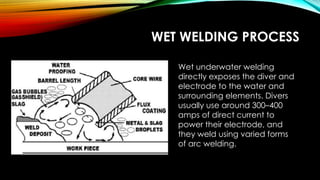

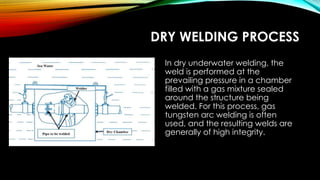

Underwater welding is a crucial technique for repairing and constructing marine structures, using special waterproof electrodes developed in 1946. It includes two main processes: wet welding, which is directly exposed to water, and dry welding, performed in a sealed chamber, each with distinct applications and requirements. Future developments focus on automation and advanced welding techniques for improved efficiency and effectiveness in underwater projects.