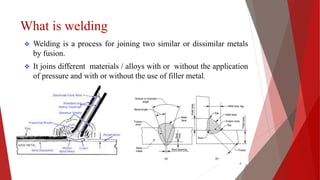

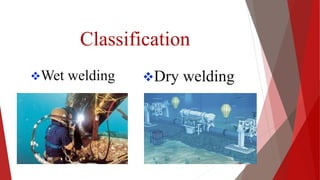

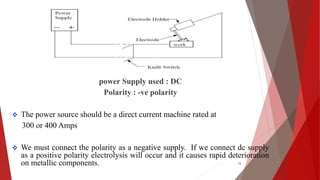

Underwater welding, first introduced by the British Admiralty, is a crucial method for repairing structures beneath water, utilizing electrical arcs for joining metals. The process includes wet welding, performed directly in water, and dry welding, which occurs in a controlled gas environment. Despite its efficiency and necessity for high-pressure applications, underwater welding poses risks such as electric shock and gas explosions, requiring strict safety precautions.